Hoisting device for large-tonnage live wire

A live wire, large-tonnage technology, applied in the direction of lifting devices, overhead lines/cable equipment, etc., can solve the problems of insulating materials such as weak bending resistance, torsion resistance, difficulty in ensuring the mechanical strength of insulating materials, and unsatisfactory allowable loads of tools. , to achieve the effect of good promotion and reference, eliminating hidden dangers of equipment, and reducing the risk of high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

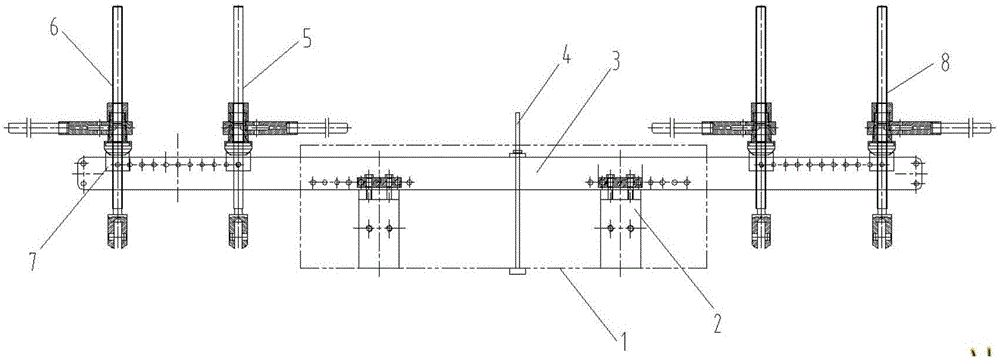

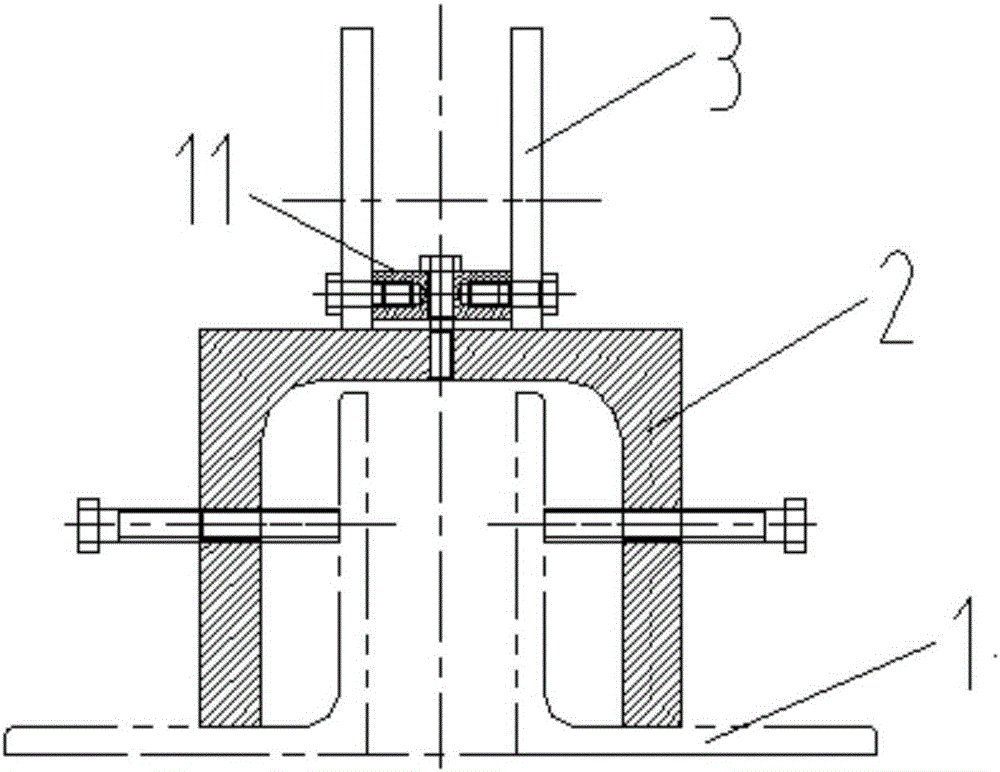

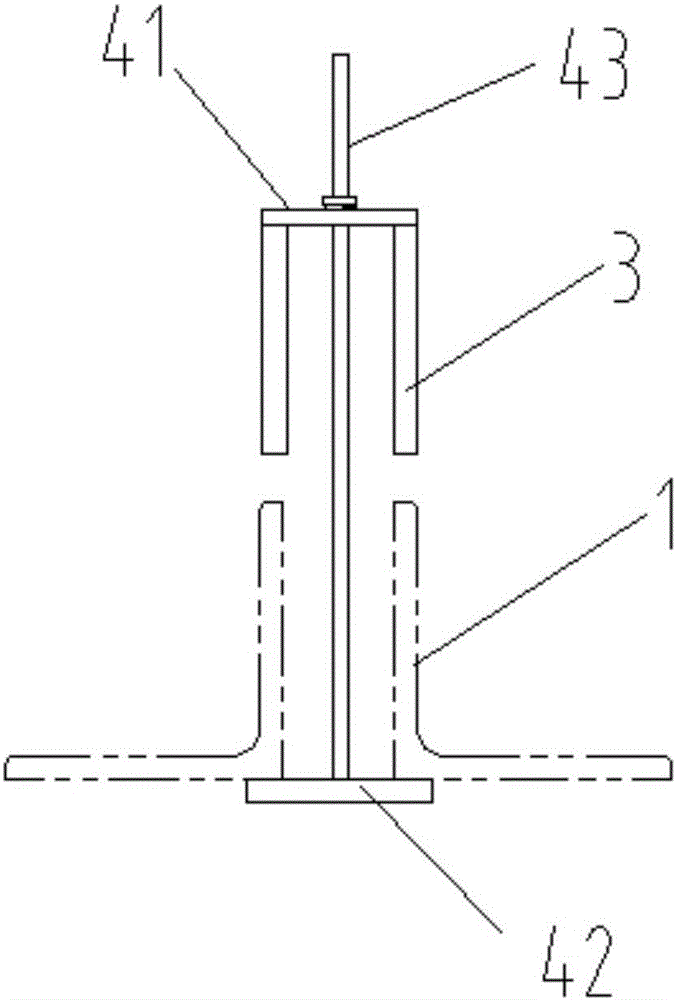

[0036] combine Figure 1 to Figure 6 As shown, a lifting device for a large-tonnage live wire includes a lifting cross arm 3, a leveling bracket 2, a reinforcing device 4 and a lifting device. Wherein, the lifting cross arm 3 includes two high-strength aluminum alloy plates with a thickness of 150 mm, and the middle of the two aluminum alloy plates is formed by fixing and combining with the aluminum alloy plates on both sides with bolts through a plurality of fixing plates 11 with a width of 150 mm. There are two leveling brackets 2 and they are respectively located on both sides of the middle section of the lifting cross arm 3. The top of the leveling bracket 2 is a flat U-shaped groove structure. The two sides of the lower part of the leveling bracket 2 are symmetrically provided with screw holes. The lower part of the leveling support 2 is fixed on the angle steel 1 of the iron tower cross arm to ensure that the uneven iron tower cross arm head is in a horizontal state, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com