Spring-type automatic spraying conjoined nozzle

An automatic spraying, spring-type technology, applied in the direction of spraying device, etc., can solve the problems of inconvenient operation, laborious, low efficiency, etc., and achieve the effect of efficient spraying operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

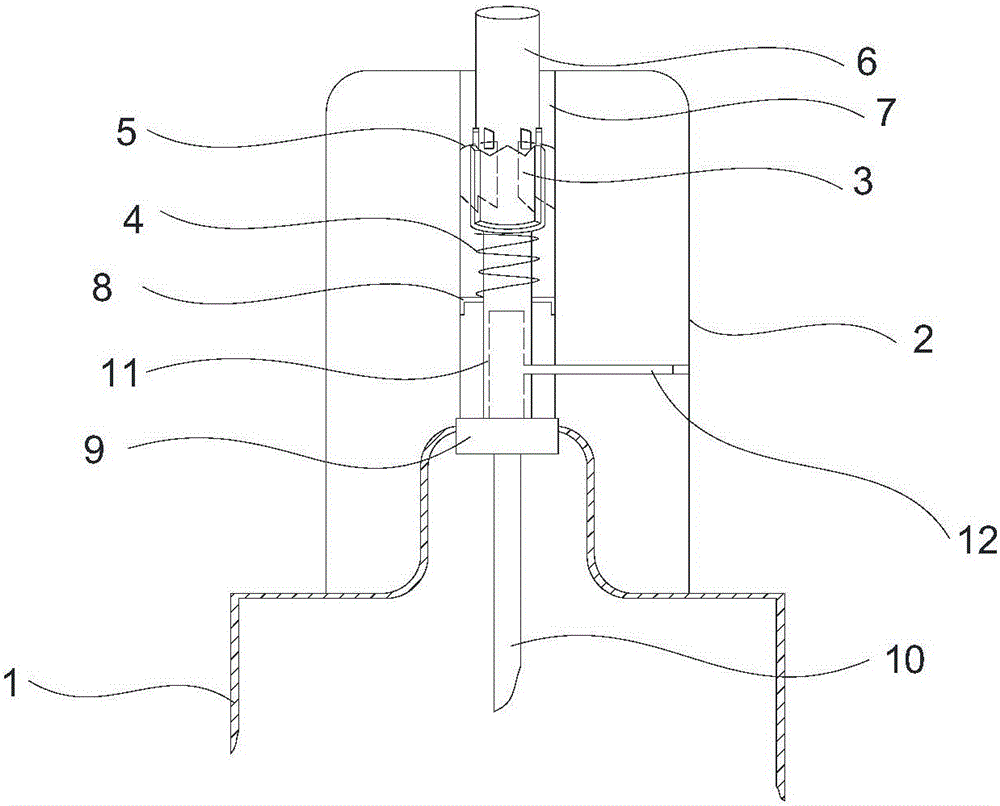

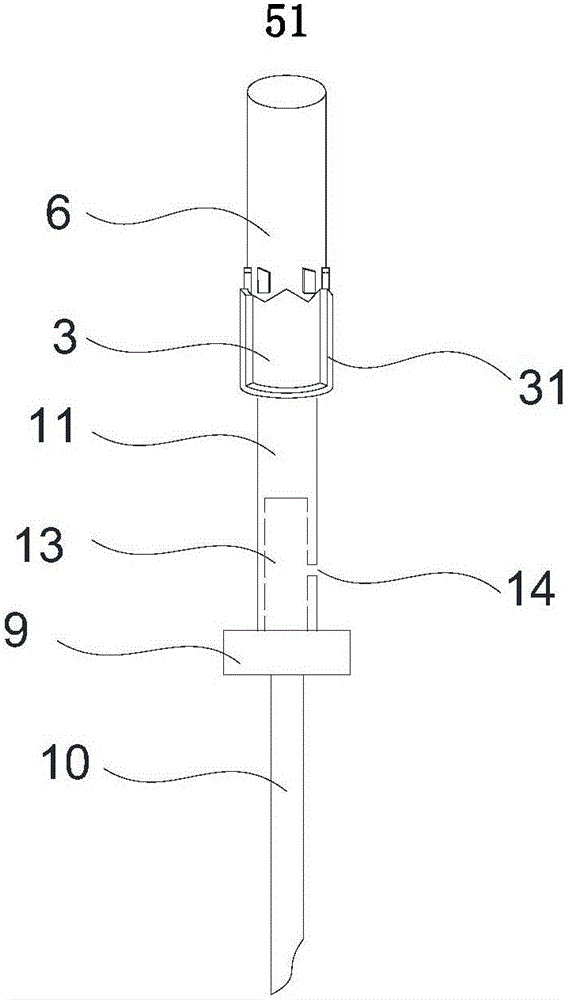

[0014] Such as Figure 1-3 As shown, the spring type automatic spraying one-piece nozzle includes a valve cover 2, an aerosol valve and a telescopic mechanism.

[0015] The aerosol valve includes a valve chamber 9 , a liquid introduction pipe 10 and a valve stem 11 , and the liquid introduction pipe 10 and the valve stem 11 are located on opposite sides of the valve chamber 9 . The valve chamber 9 is fixed on the filling mouth of the aerosol can 1 , one end of the liquid introduction pipe 10 is connected to the valve chamber, and the other end is connected to the inside of the aerosol can 1 . The valve stem 11 is connected to the valve chamber 9 and has a cavity 13 inside, and the cavity 13 communicates with the valve chamber 9; the valve stem 11 is provided with a discharge port 14 communicating with the cavity 13 . Compress the valve stem 11, the valve in the valve chamber 9 opens, the aerosol in the aerosol can 1 can enter the cavity 13 of the valve stem 11 through the liq...

Embodiment 2

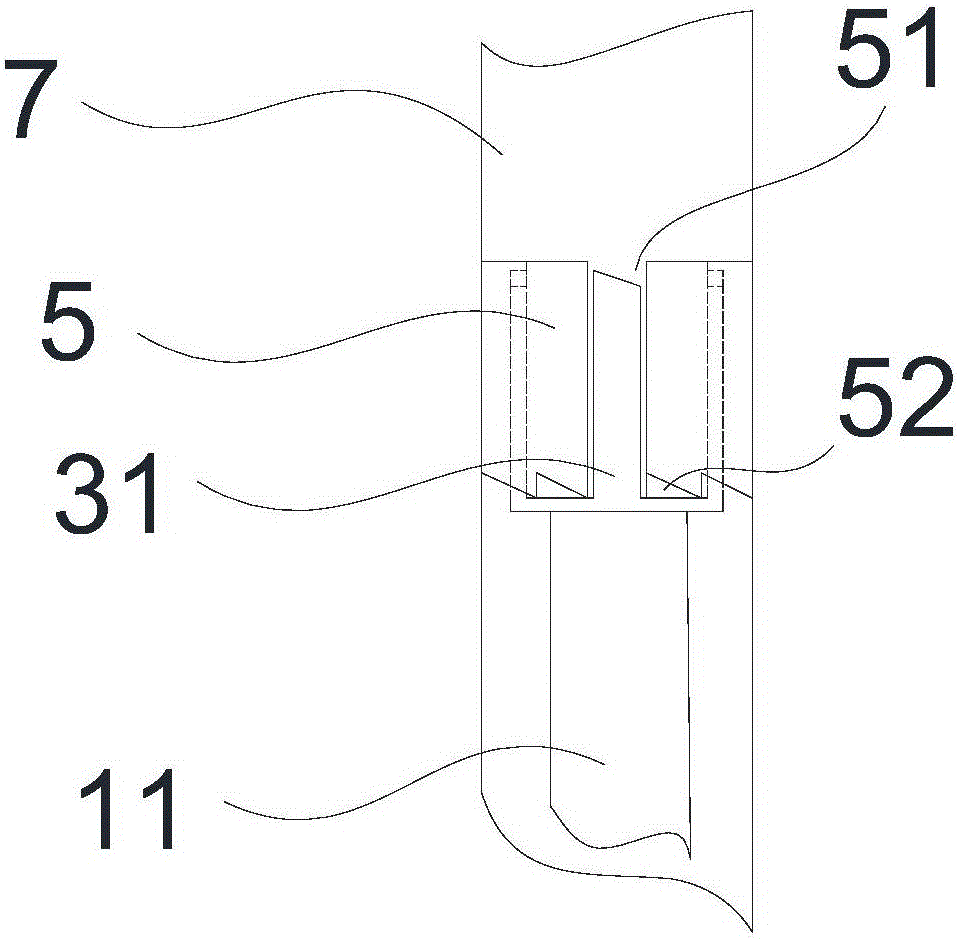

[0020] The difference between this embodiment and the spring-type automatic spraying one-piece spray head of Embodiment 1 is that the rear end of the indexing drum 3 is integrally connected with the end of the valve stem 11; The telescoping groove sleeve 5 forms deep grooves 51 and shallow grooves 52 that are staggered between the corresponding indexing claws 31, but directly forms deep grooves 51 and shallow grooves that are staggered between the corresponding indexing claws 31 on the inner wall of the accommodating channel 7 52. Other structures are the same as in Embodiment 1.

[0021] The spring-type automatic spraying one-piece nozzle of the present invention uses the spring and the ejector pin type mechanical telescopic structure to provide the driving force to drive the valve stem to achieve the cycle function of automatic spraying when pressed and automatic stop when pressed again, so that the hand-sprayed aerosol spraying can achieve automatic spraying. The effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com