A kind of carbon dioxide pressure relief and fire extinguishing technology and equipment in goaf

A technology of carbon dioxide and liquid carbon dioxide, applied in mining equipment, fire prevention, mining equipment, etc., can solve problems such as unsatisfactory control effect, limited range of control area, complex process, etc. The effect of convenient installation and technical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

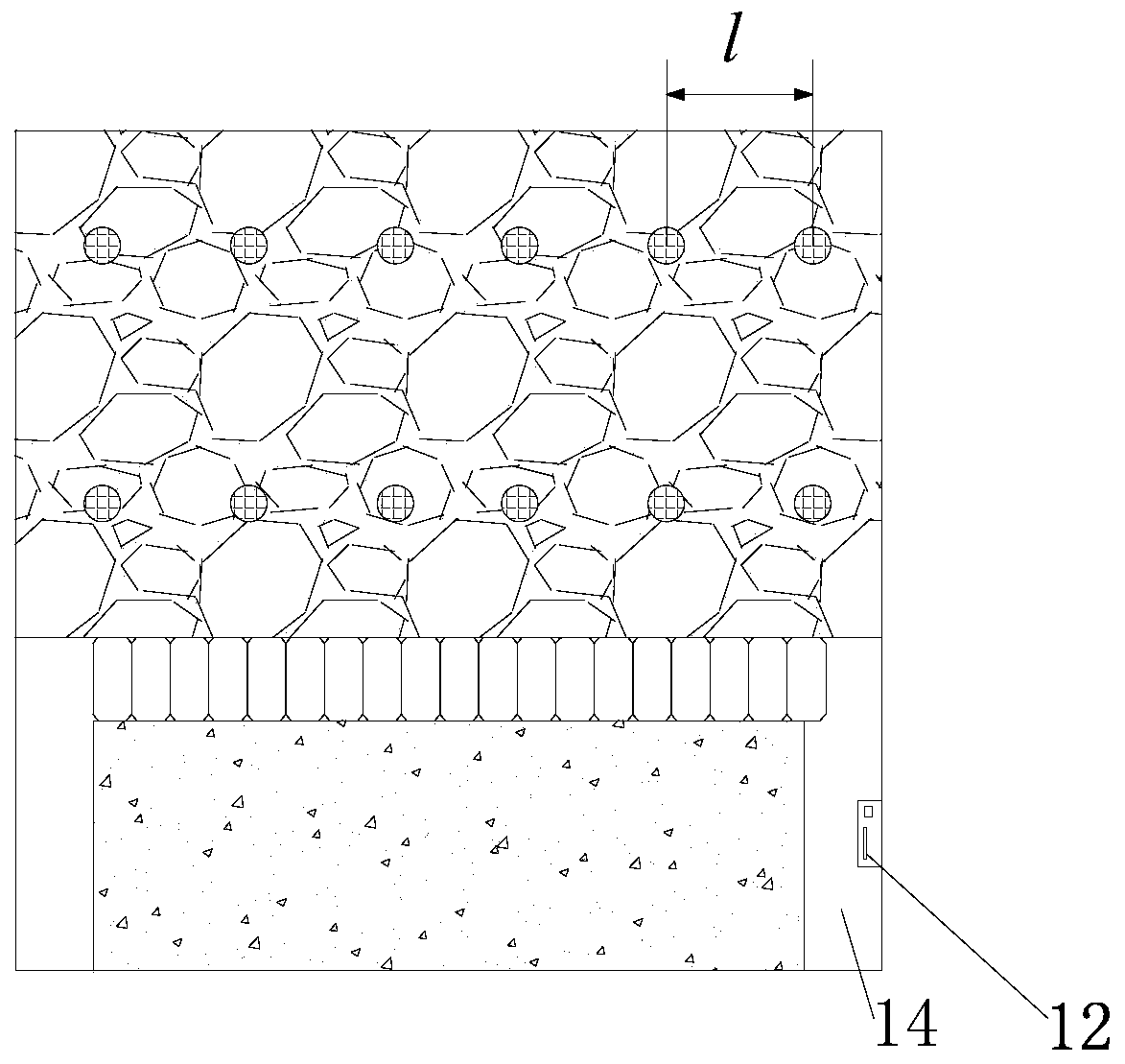

[0039] The present invention provides a technology and equipment for carbon dioxide pressure relief and fire prevention in goafs. The following drawings and examples are used to practically apply this technology with the engineering background of prevention and control of spontaneous combustion of coal left in goafs in the 1501 working face of a certain mine. The technical scheme of the present invention is further described in detail.

[0040] At first the technical equipment included in the present invention is described as follows:

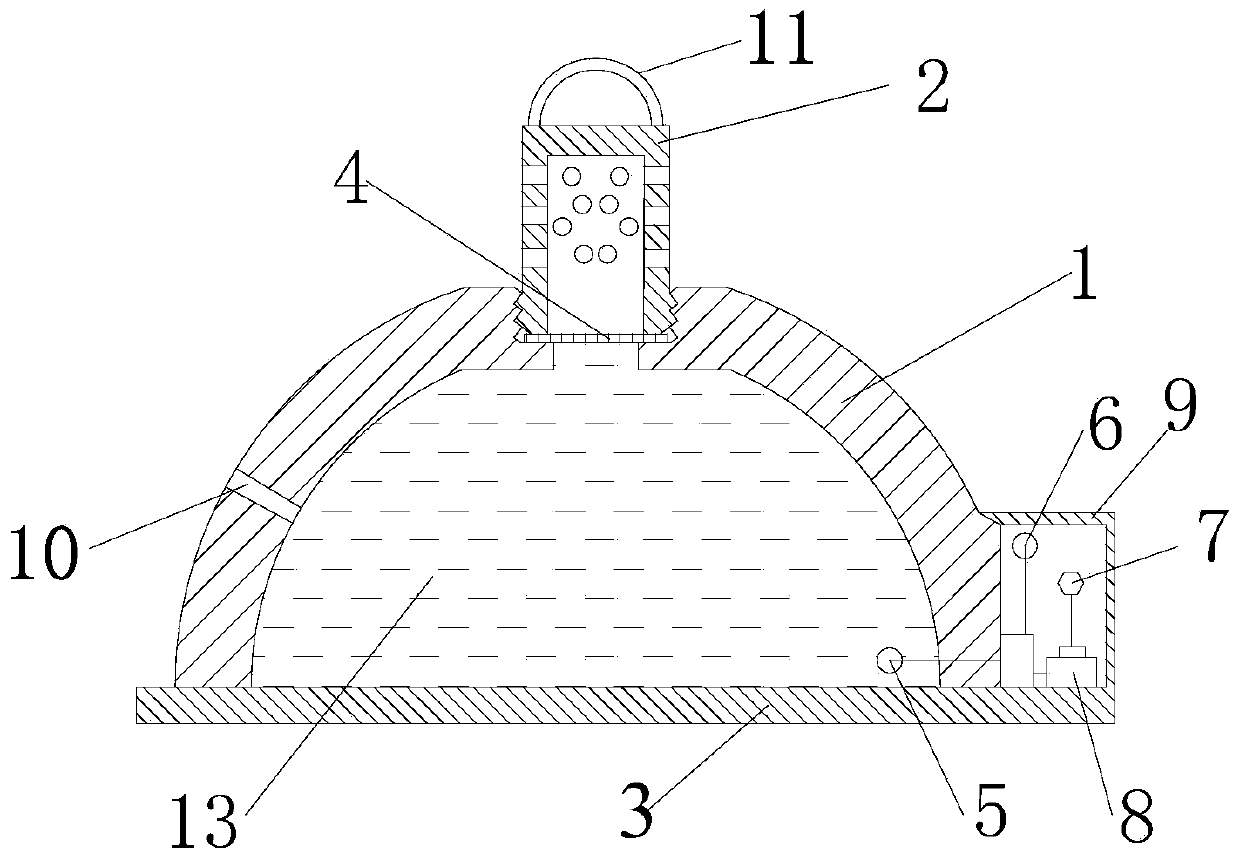

[0041] combine figure 1 As shown, a carbon dioxide pressure relief and fire prevention technology and equipment for gobs, the technical equipment mainly includes a carbon dioxide pressure relief tank.

[0042] The carbon dioxide pressure relief tank includes a tank body 1, a pressure relief head 2, a base 3, a rupture disc 4, a hydraulic sensor 5, a temperature sensor 6, a wireless signal transmitter 7, an explosion-proof power supply 8, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com