Non-contact spring compression reset type magnetic switch

A magnetic switch, non-contact technology, applied in the field of switches and machinery, to achieve the effect of high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

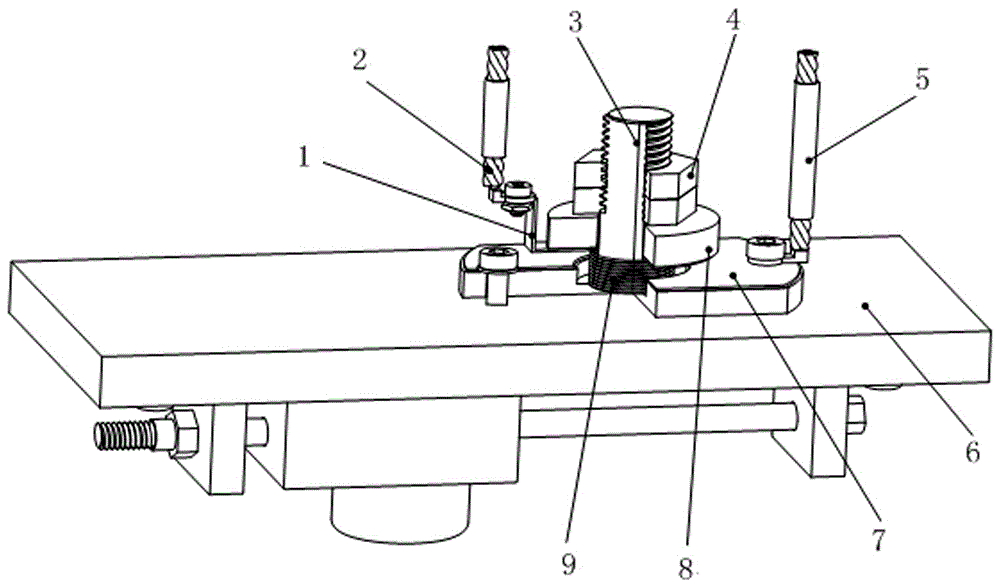

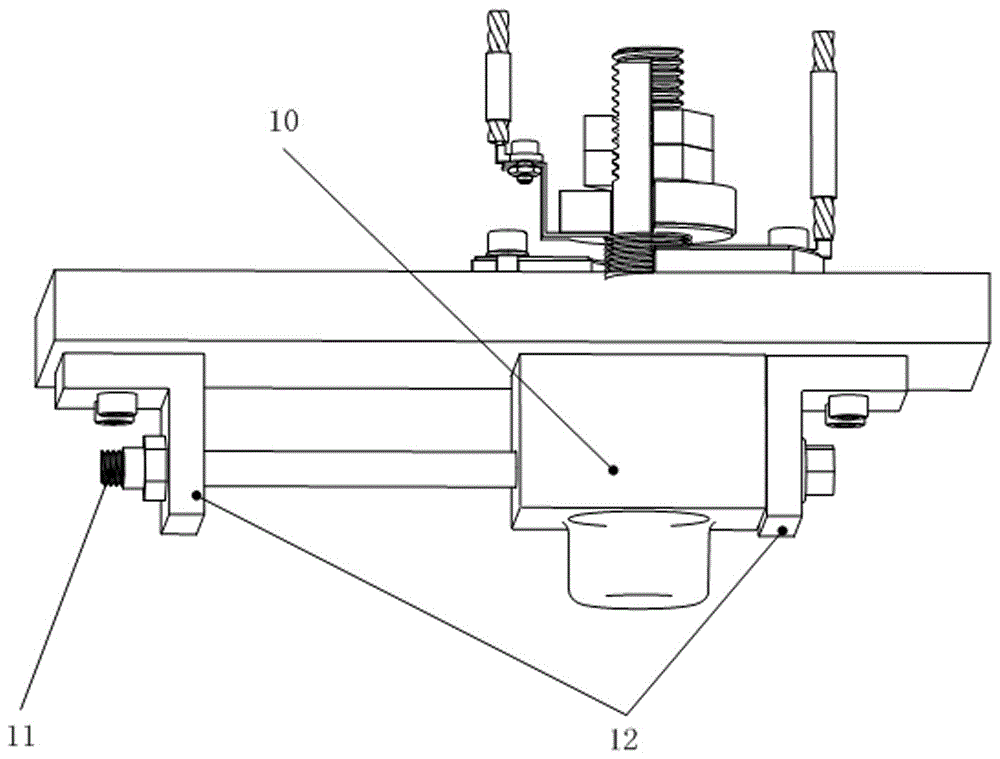

[0018] As shown in the figure, the non-contact spring compression reset type magnetic switch includes an in-cabin circuit conduction reset mechanism and an external magnetic switch outside the cabin; the in-cabin circuit conduction and reset mechanism is arranged in the inner cavity of the housing, and the in-cabin circuit The conduction reset mechanism includes a fixed shaft seat 3, a limit nut 4, a strong magnetic steel 8, a contact copper sheet 1, a conductive copper sheet 7, a compression spring 9, a contact lead wire 2 and a shaft seat lead wire 5; the fixed shaft seat 3 passes through The two screws are set in the shell, the conductive copper sheet 7 is laid on the fixed shaft seat 4, the limit nut 4, the strong magnetic steel 8, the contact copper sheet 1 and the compression spring 9 are arranged on the fixed shaft seat 3 in turn from top to bottom, The contact copper sheet 1 is connected with the contact lead wire 2 through screws, and the fixed shaft seat is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com