Novel assembling mechanism of radio-frequency coaxial connector

A radio frequency coaxial and connector technology, applied in the direction of two-part connection device, connection, fixed/insulated contact member, etc., can solve the problems of signal interruption, easy breakage of core wire, complicated and difficult search, etc., to prevent external pulling The effect of moving and connecting firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

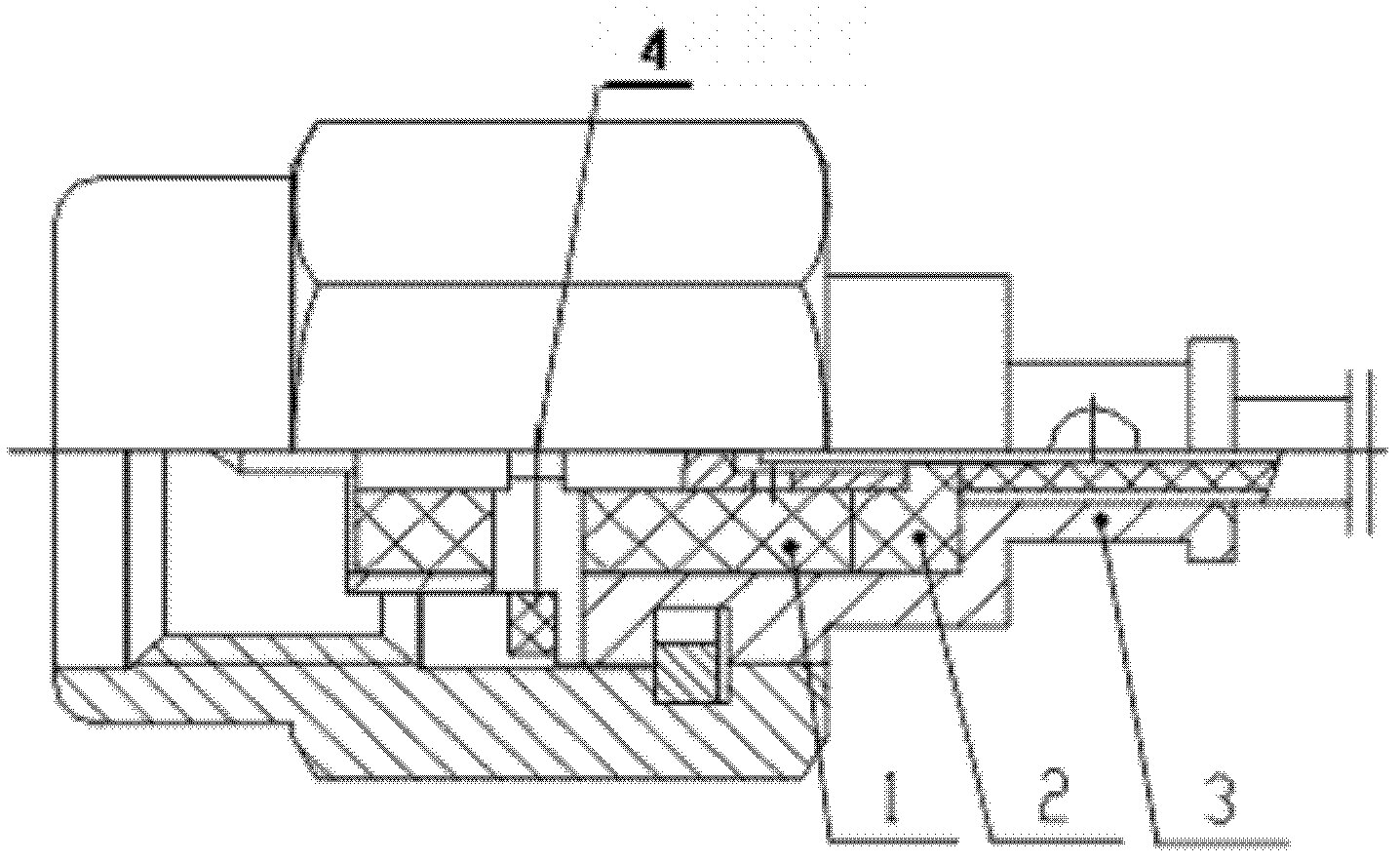

[0014] As shown in Figure 2, a new type of mounting mechanism for a radio frequency coaxial connector of the present invention includes an inner conductor, an outer conductor 3, and a first insulator 1 arranged in the outer conductor 3 and adjacent to the first insulator 1 and placed The second insulator 2 outside the first insulator 1, the first insulator 1 is arranged inside the second insulator 2, the inner conductor, the first insulator 1 and the inner hole of the outer conductor 3 are overlapped to form a filling port 4, and the filling port 4 is formed. The filling port 4 adopts epoxy resin filling and packaging mechanism. The size of the inner hole of the second insulator 2 is equal to the size of the thin cable core wire, which is used to straighten the core wire to ensure that the core wire does not move axially. The outer conductor 3 and the thin cable The shielding layer of the cable adopts a welding mechanism.

[0015] The installation principle of a new type of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com