Rail vehicle end sleeper outside structure

A rail vehicle and external structure technology, applied in the direction of railway car body components, chassis, traction devices, etc., can solve the problems of large welding volume, inconvenient assembly, unfavorable interface installation, etc., to achieve enhanced stability and reliability, and convenient installation , the effect that the structure is easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

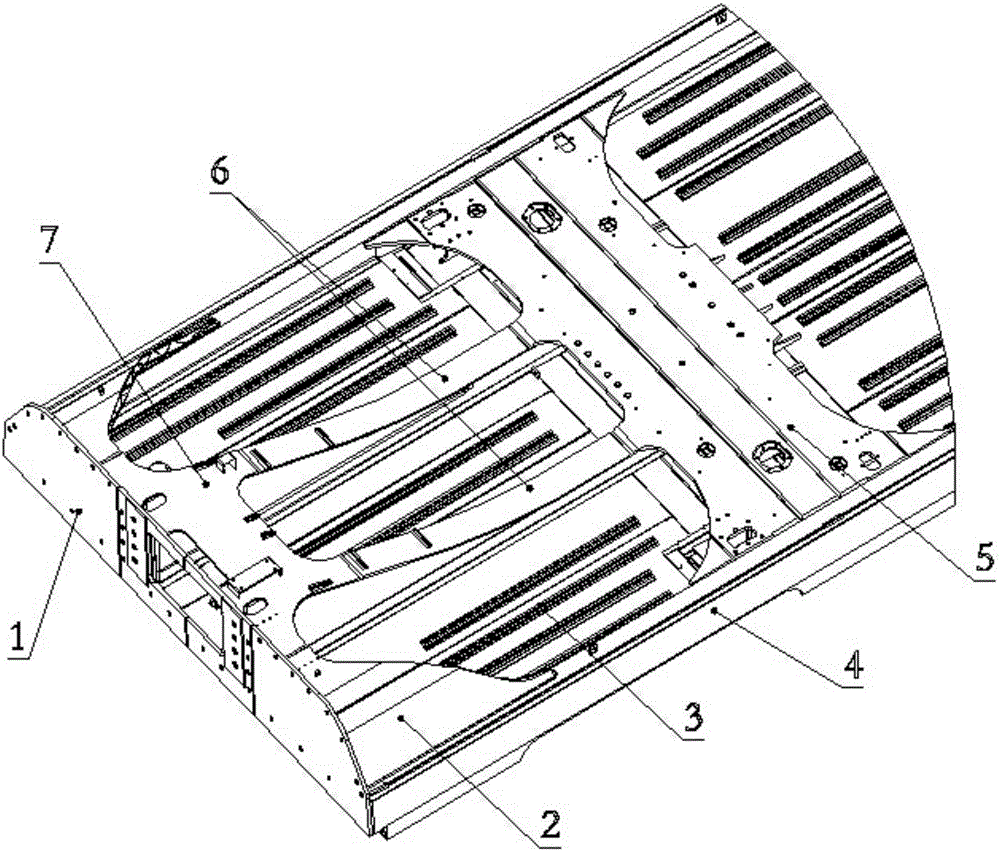

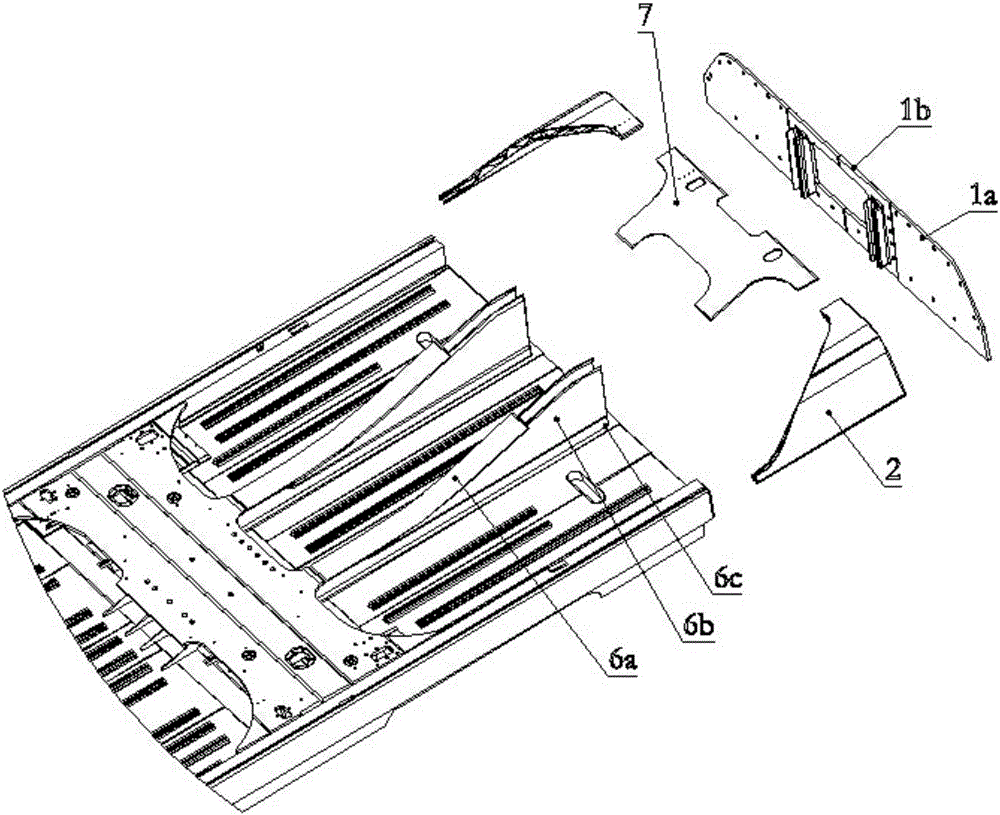

[0018] figure 1 , figure 2 The outer pillow structure at the end of the rail vehicle shown includes a coupler mounting seat 1, a corbel 5, a traction beam 6, a support plate 2, and an aluminum floor 3. One side of the coupler mounting seat 1 is provided with an aluminum floor 3, and the two sides of the aluminum floor 3 are connected. Underframe side beam 4, underframe side beam 4 is connected with coupler mounting seat 1, corbel 5 and several traction beams 6 are arranged on aluminum floor 3, one end of each traction beam 6 is connected with corbel 5, each traction beam 6 The other end is connected to the coupler mounting seat 1 through the traction beam transition plate 7, both ends of the traction beam transition plate 7 are connected to the underframe side beam 4 through the support plate 2, and one side of the support plate 2 is connected to the coupler mounting seat 1.

[0019] The draw beam 6 has a radian and is arranged from high to low. The high end of the draw beam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap