Automatic centering device

A technology of automatic centering and height adjustment device, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of inaccuracy of measurement results, inaccurate data results, uneven force on wheels, etc. Improve work efficiency and measurement accuracy, data results are true and accurate, and avoid accidental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

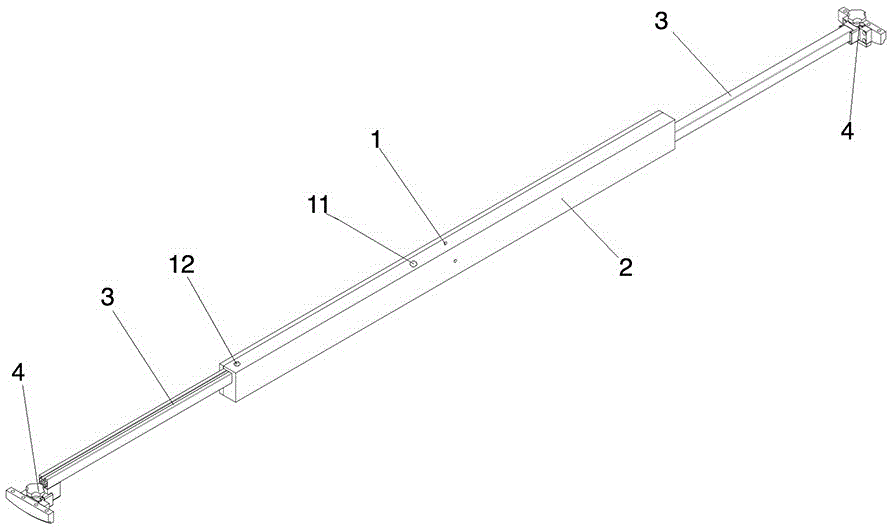

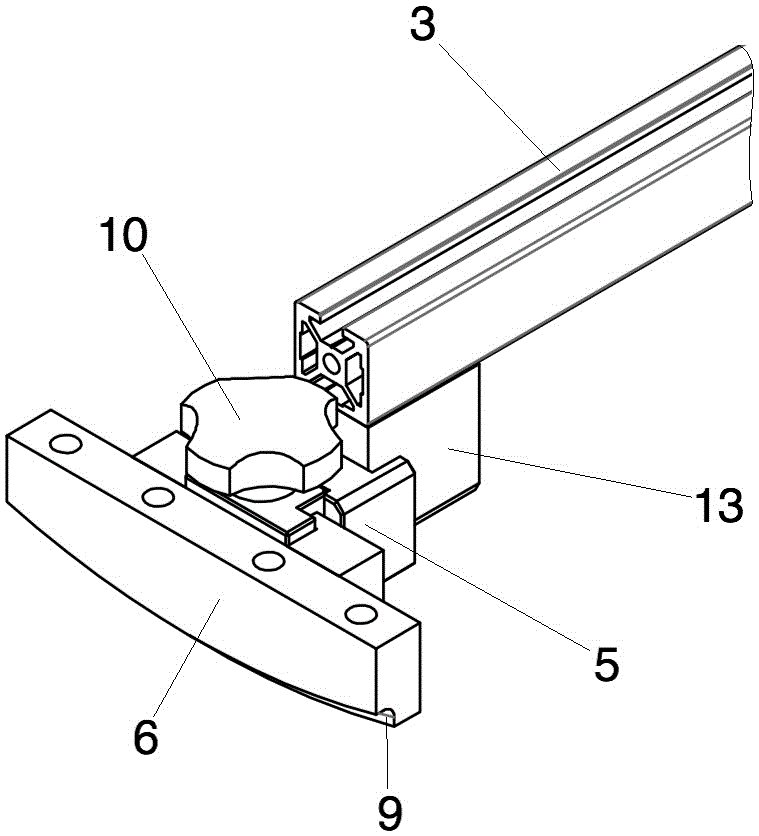

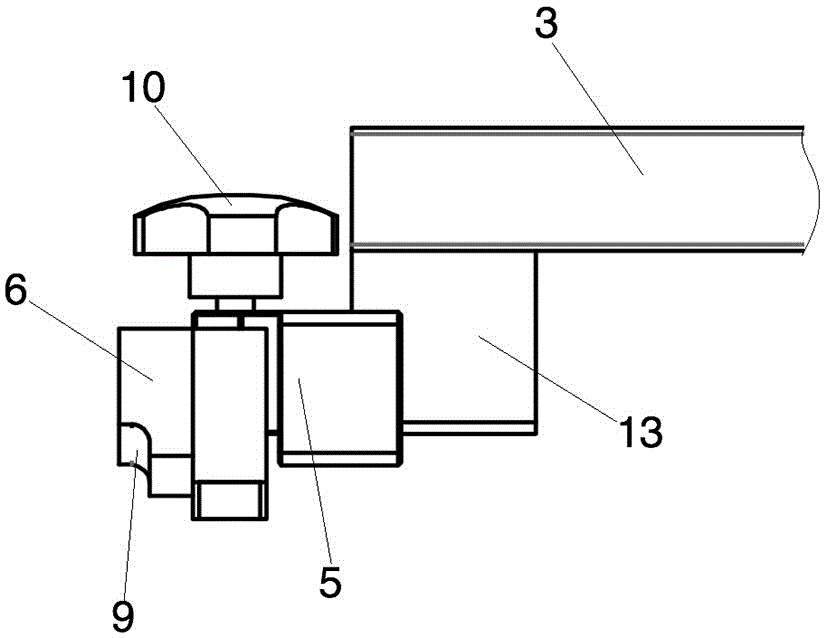

[0027] Such as figure 1 and 6 As shown: this embodiment is an automatic centering device, including a telescopic body 2 provided with a central point 1, and two telescopic rods 3 are arranged inside the telescopic body 2, and the two telescopic rods 3 are connected from two ends of the telescopic body 2 respectively. Both ends extend outward or contract inward at the same time, and the stroke lengths of the two telescopic rods 3 when extending outward or contracting inward are equal, such as Figure 2-4 As shown: a hub connection mechanism 4 is provided on the end of the telescopic rod 3, and the hub connection mechanism 4 includes a height adjustment device 5 that is slidingly connected to the end of the telescopic rod 3 and is arranged on the outer surface of the height adjustment device 5 and contacts with the wheel hub. Connected hub positioning block 6; in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com