Automobile hub bearing unit sealing ring sealing performance testing machine

A technology of automobile wheel hub and sealing performance, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, which can solve the problems of sealing ring failure and achieve the effect of relative rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

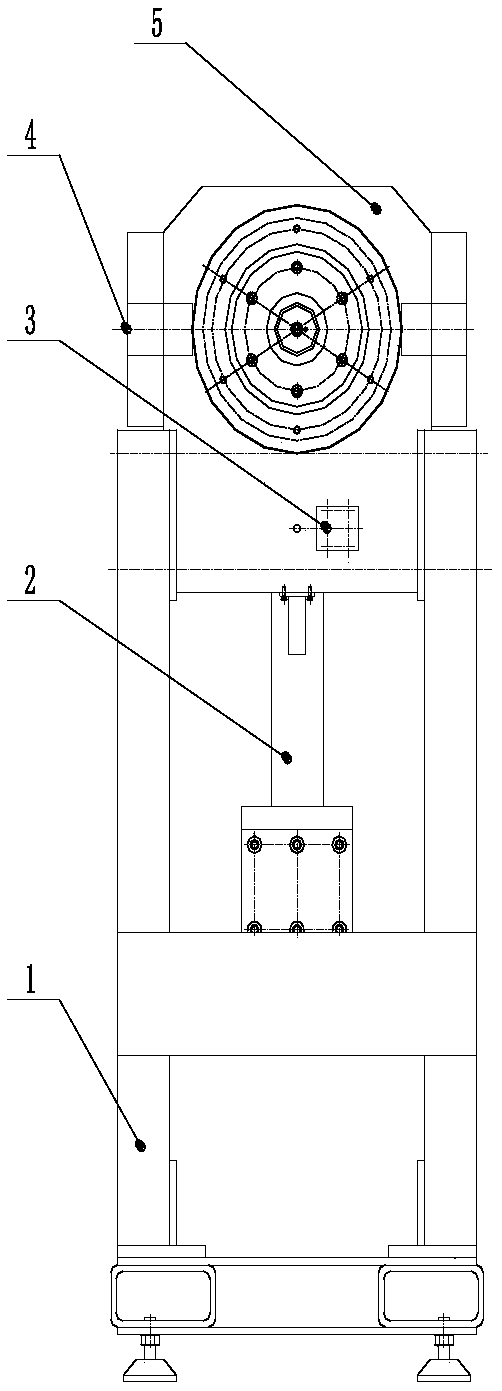

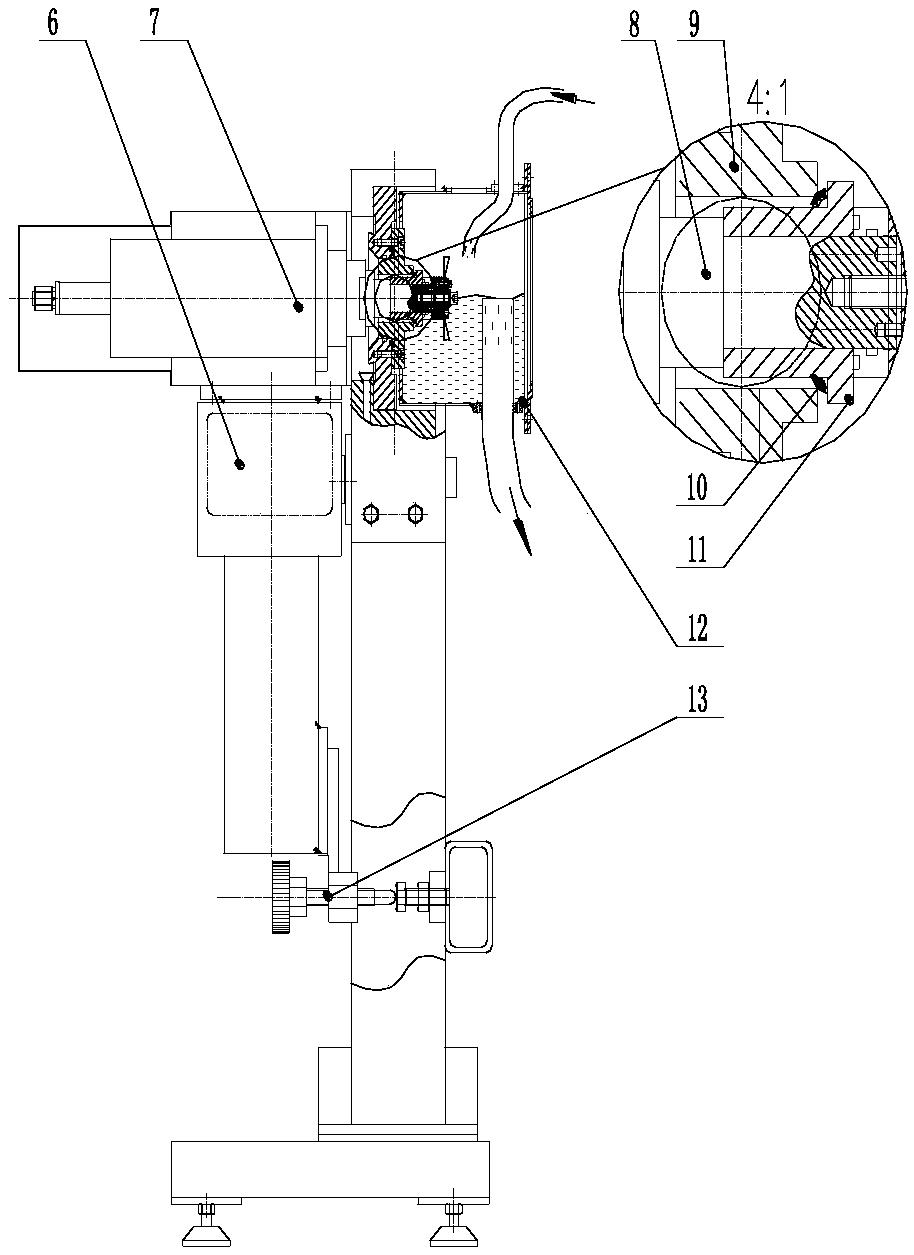

[0025] refer to figure 1 and figure 2 , the automobile hub bearing unit sealing ring sealing performance testing machine, including a frame, also includes a main shaft component installed on the frame 1, a simulated bearing component, an inclination adjustment mechanism and a mud pool 12 filled with test intervention mud;

[0026] The main shaft part includes a motor 7 and a main shaft 8, the motor 7 and the main shaft 8 are connected in transmission, and the main shaft 8 can swing around the rotating shaft 4 on the main body above the frame 1;

[0027] The simulated bearing component includes a simulated outer ring 9, a sealing ring 10 and a simulated inner ring 11, the simulated outer ring 9 is installed on the main body 5, and the simulated inner ring 11 is installed on the main shaft 8, and the simulated inner ring 11 rotates with the main shaft 8; the relative position of the simulated outer ring 9 and the simulated inner ring 11 is determined, and the simulated outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com