Crimp connector and method of manufacturing same

A manufacturing method and connector technology, applied in contact manufacturing, welding/welding connection, connection, etc., can solve problems such as mutual opening of spring parts, size deviation of spiral structure, relative position of difficult-to-upper side plate parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

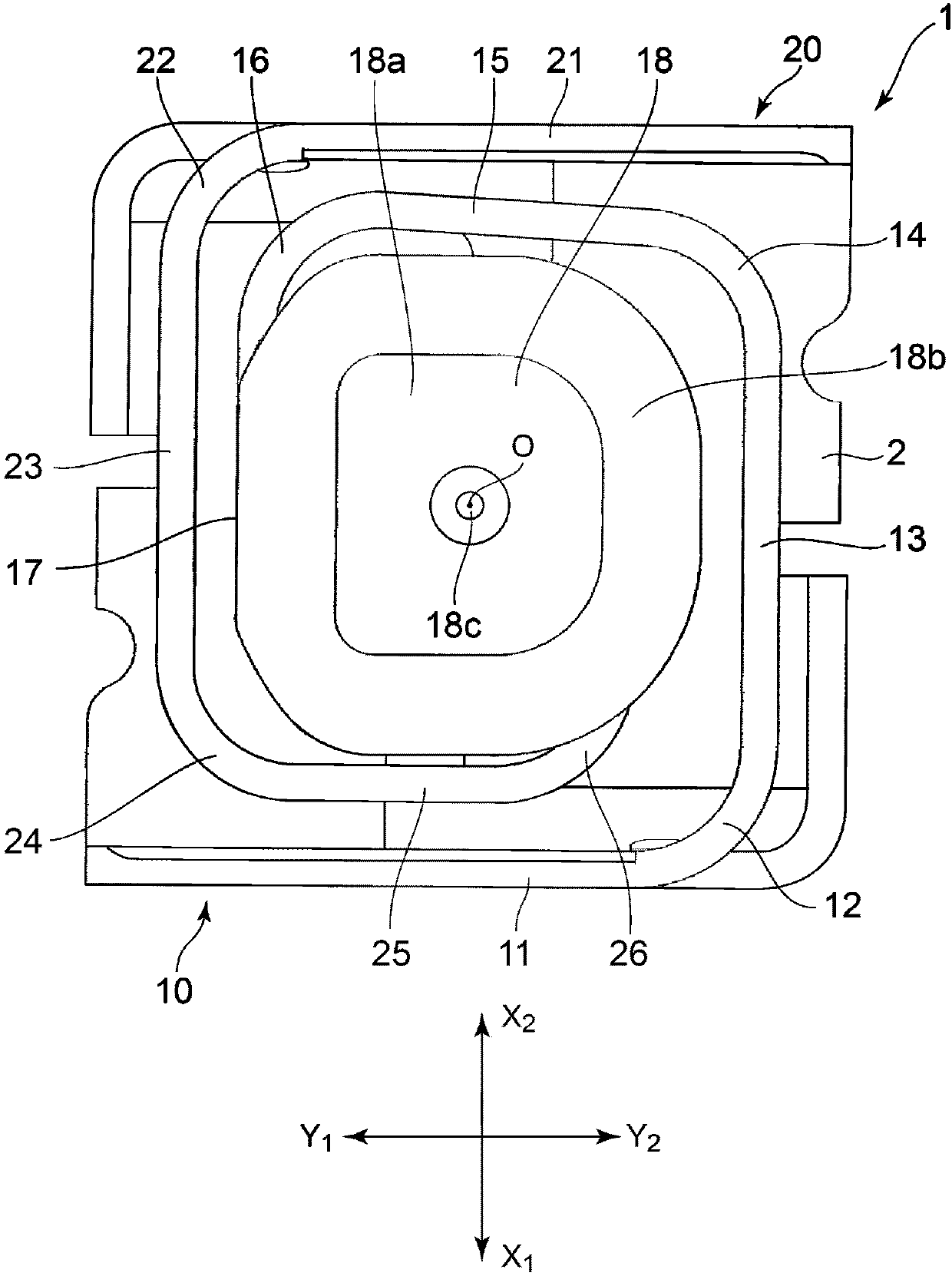

[0044] The crimp connector 1 of the embodiment of the present invention is formed by bending a conductive metal plate material by press working. The metal plate material is copper or copper alloy, and is formed of Corson alloy (Cu-Ni-Si alloy) in the embodiment.

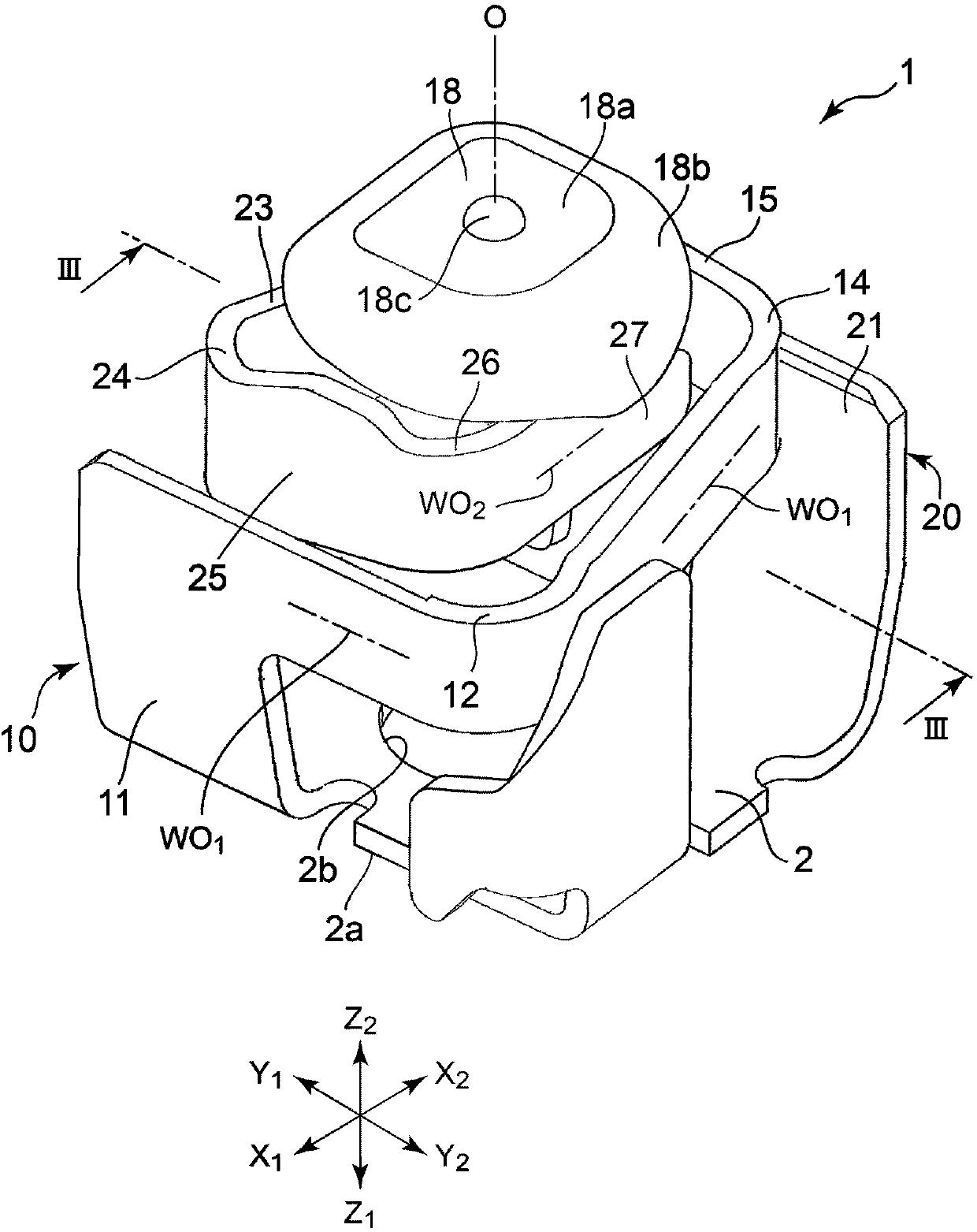

[0045] Crimp connector 1 figure 1 The dimensions in the X direction and the Y direction in the plane shape shown are respectively 2mm×2mm or less, preferably 1.5mm×1.5mm or less. figure 2 The height dimension in the Z direction in the free state where no load is applied is shown to be 1.5 mm or less, preferably about 1 mm.

[0046] This crimping connector 1 is used for connecting parts between circuit boards, connecting parts between circuit boards and electronic components such as ICs, or circuit boards and wiring cables (flexible wiring cables) by mounting a plurality of them on a circuit board. 的连接部, etc.

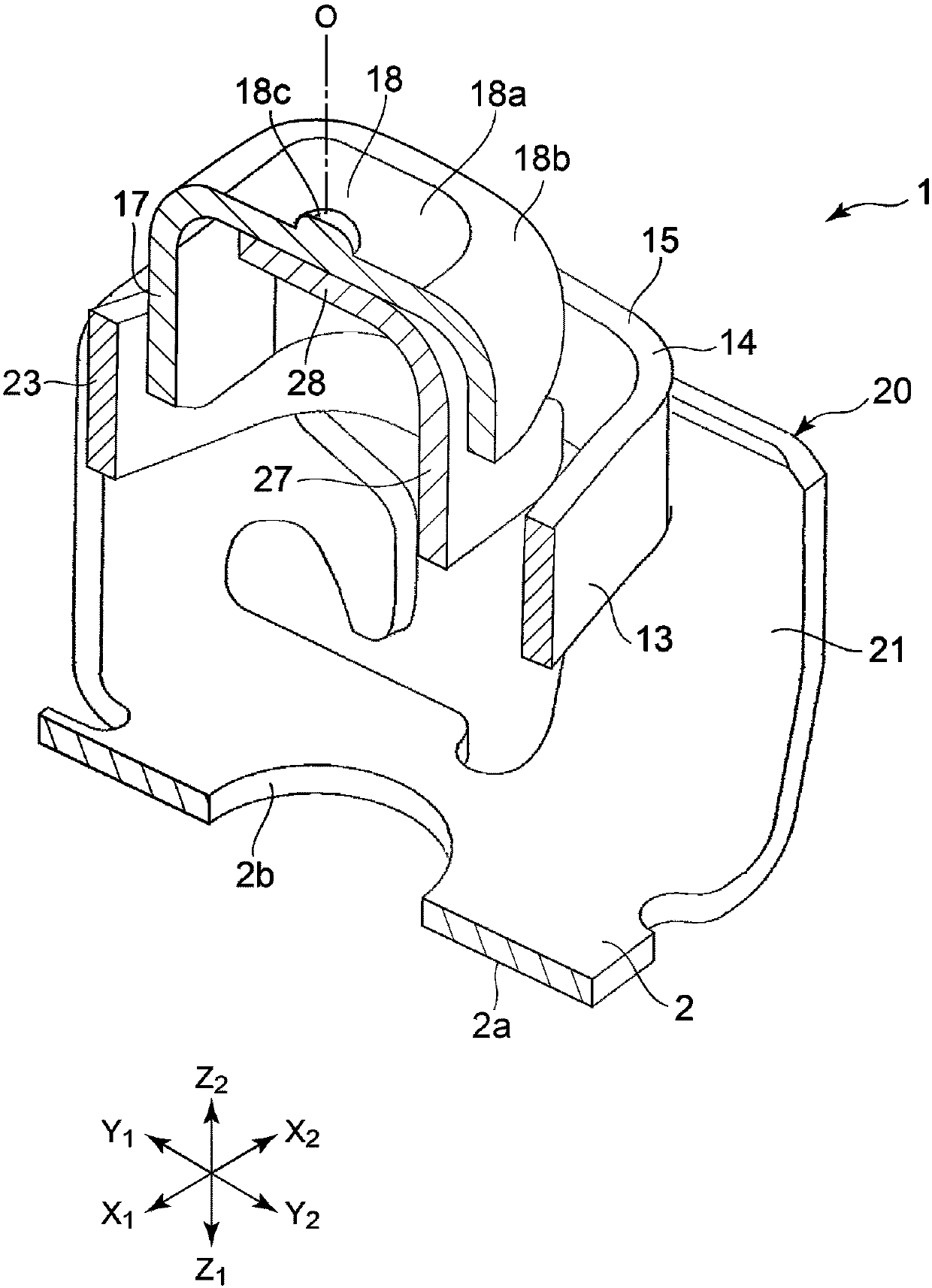

[0047] in figure 2 with image 3 Shown in is the crimp connector 1 in a free state where no load is applied. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com