Crimp connector and manufacturing method thereof

A manufacturing method and connector technology, which is applied in the direction of contact manufacturing, welding/welding connection, connection, etc., can solve problems such as the relative position of the flat plate part on the difficult upper side, the size deviation of the spiral structure, and the mutual opening of the spring parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The crimp connector 1 according to the embodiment of the present invention is formed by bending a conductive metal plate by press working. The metal plate is copper or a copper alloy, and is formed of Corson alloy (Cu—Ni—Si alloy) in the embodiment.

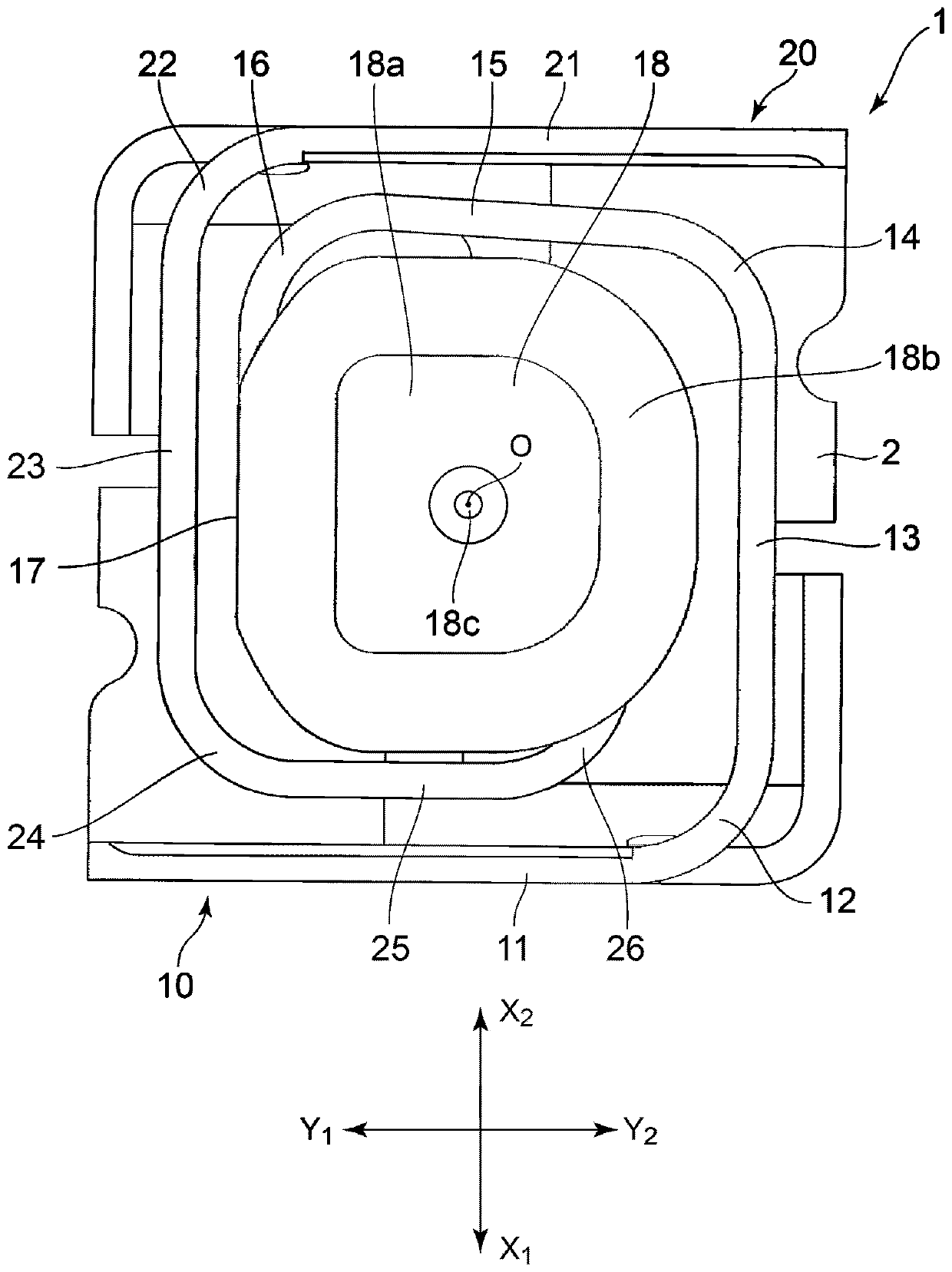

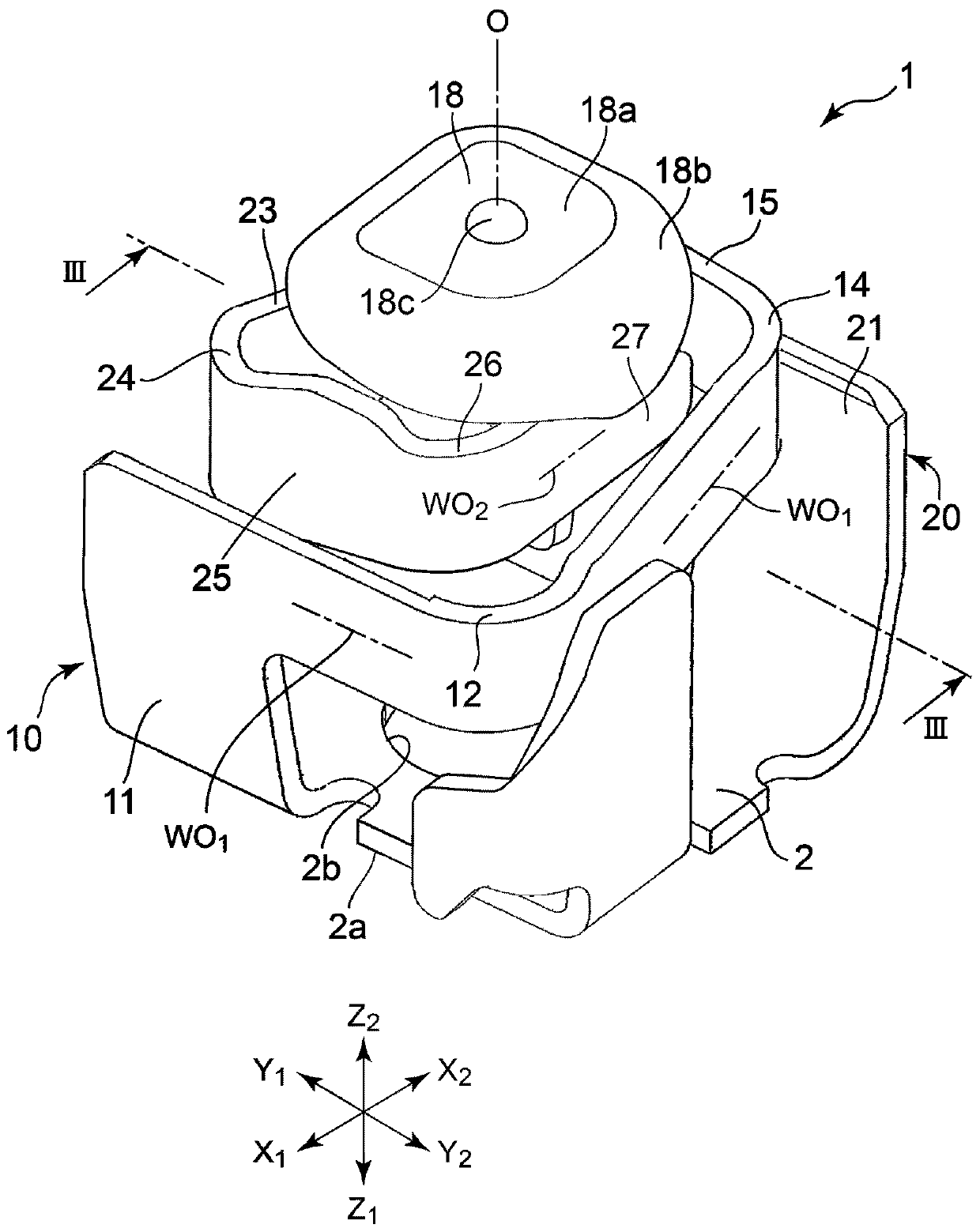

[0045] Crimp Connector 1's figure 1 The dimensions of the X-direction and the Y-direction in the shown planar shape are respectively 2 mm × 2 mm or less, preferably 1.5 mm × 1.5 mm or less. figure 2 The height dimension in the Z direction in the free state with no load applied is 1.5 mm or less, preferably about 1 mm.

[0046] This crimp connector 1 is used for a connection between circuit boards, a connection between a circuit board and an electronic component such as an IC, or a circuit board and a wiring cable (flexible wiring cable) by mounting a plurality of them on a circuit board. the connection part, etc.

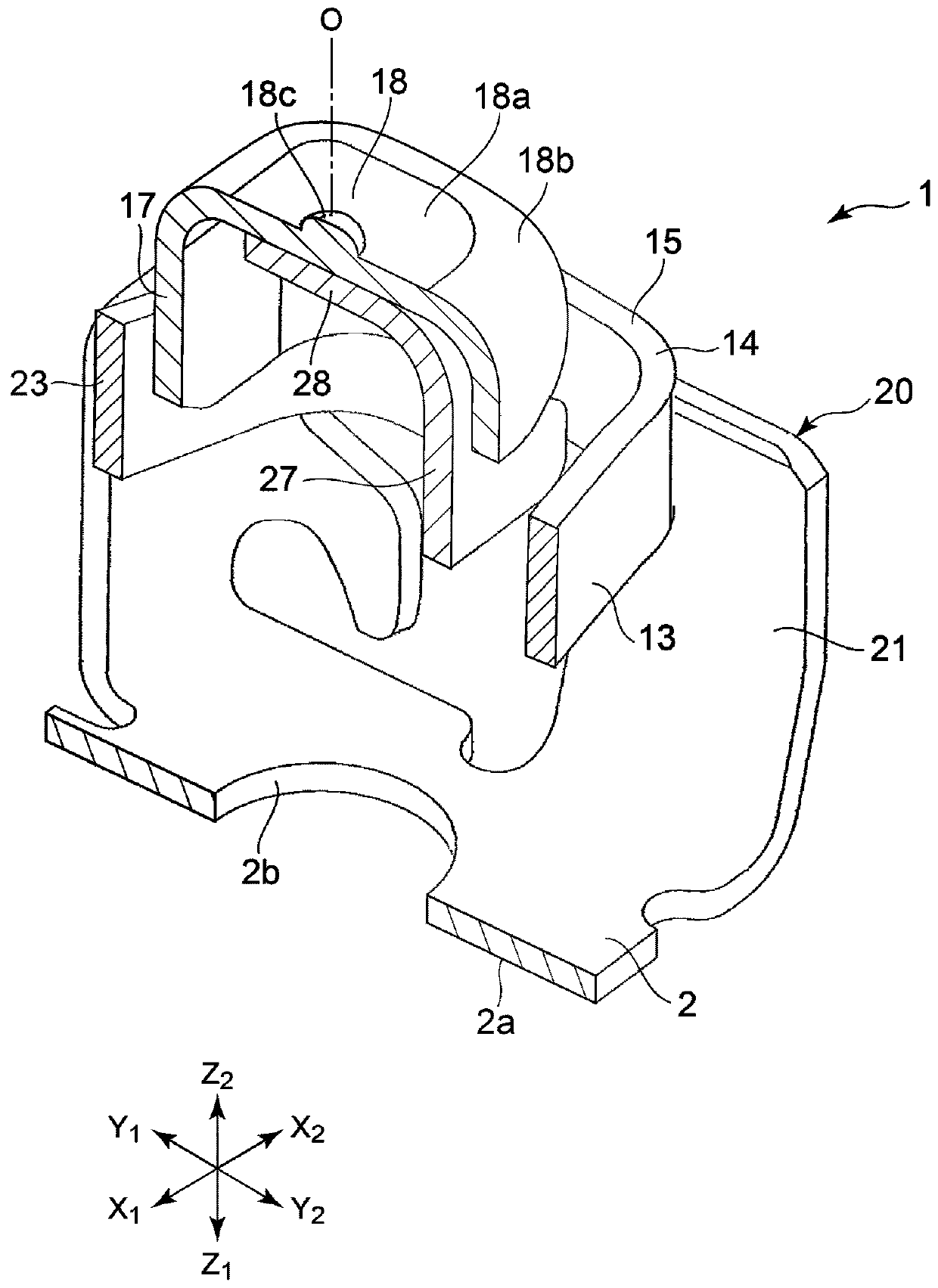

[0047] exist figure 2 and image 3 shows the crimp connector 1 in a free state with no load applied. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com