Shakeproof structure of starting resistor

A technology of starting resistance and anti-vibration structure, applied in the direction of resistors, resistor components, resistor installation/support, etc., can solve the problems of aluminum shell resistance falling apart, starting resistance failure, aluminum shell resistance falling off, etc., to reduce the degree of vibration , reduce vibration and avoid the effect of internal disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described in conjunction with the following examples.

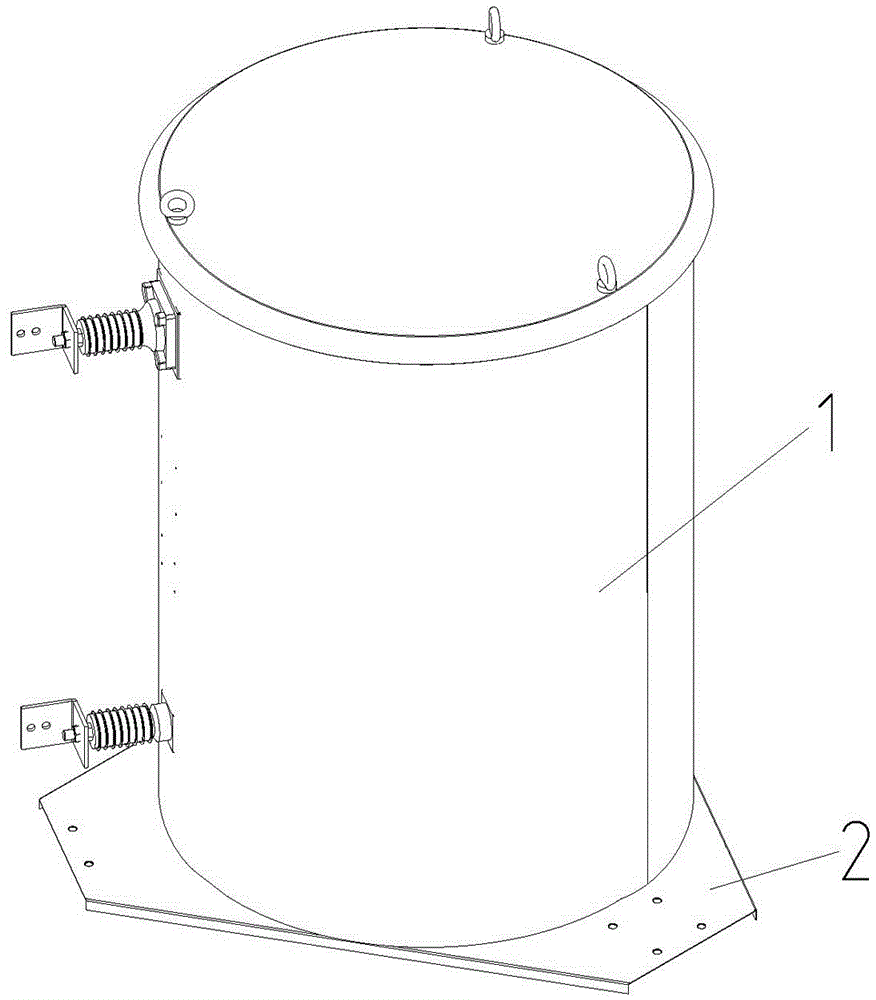

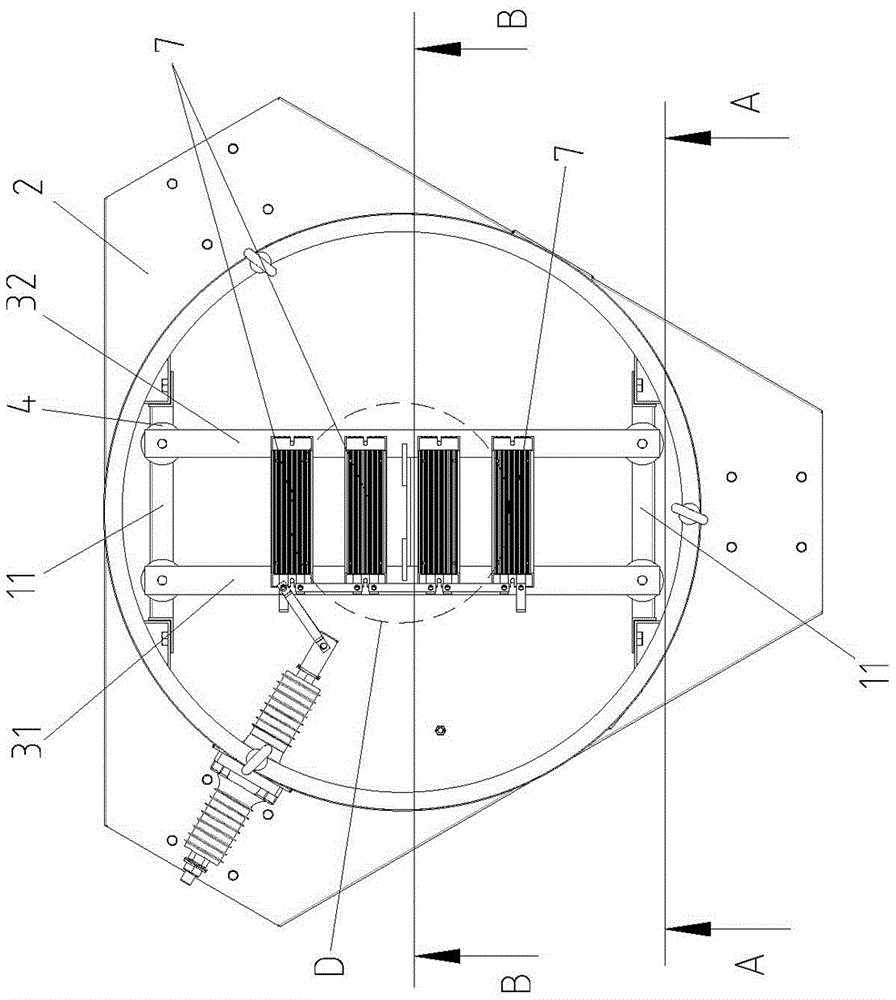

[0028] See figure 1 , figure 2 , The starting resistor has a box body 1 , and the box body 1 has a bottom plate 2 . A mounting rod 11 is fixedly connected in the box body 1 .

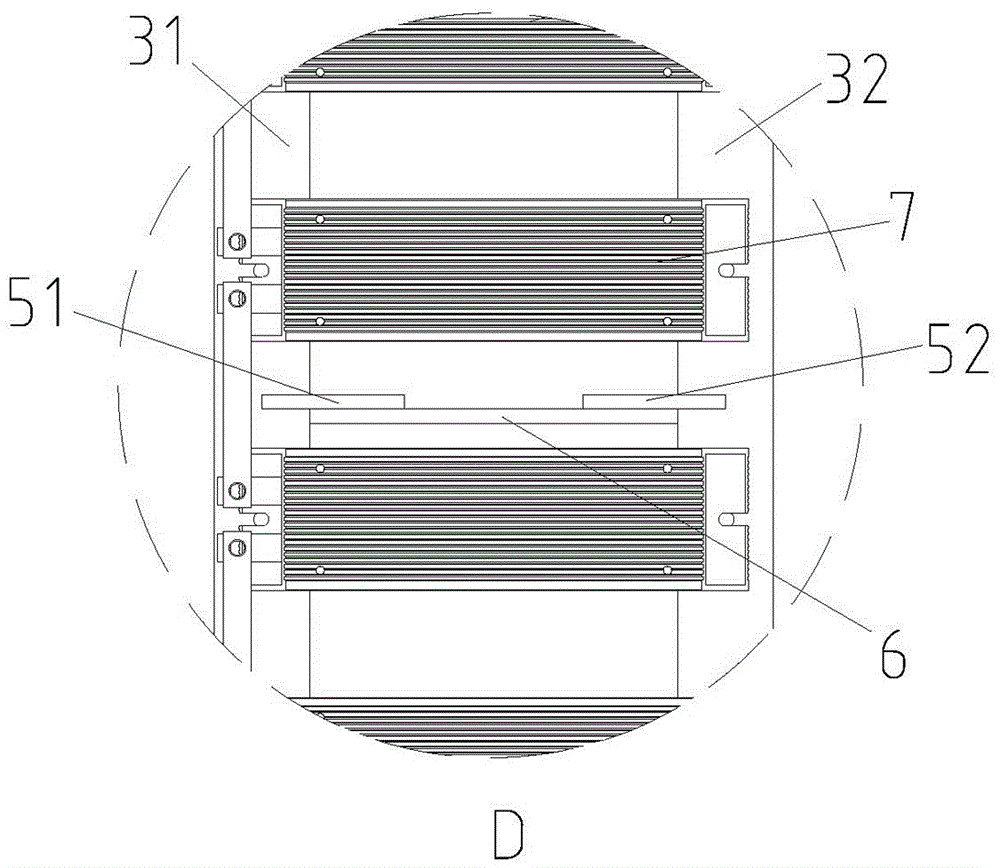

[0029] See figure 2 The shockproof structure of the starting resistor provided in this embodiment includes a first installation bar 31 and a second installation bar 32 arranged laterally at a certain distance. The respective ends of the first installation bar 31 and the second installation bar 32 are fixedly connected to the installation rod 11 to realize the fixing of the ends of the first installation bar 31 and the second installation bar 32 . The first installation strip 31 and the second installation strip 32 are respectively used for fixing the two ends of at least one flat aluminum shell resistor 7 (combined image 3 ).

[0030] combine Figure 4 , Figure 5 , the first mounting bar 31 is on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com