Automatic drilling device for sphygmomanometer case

A drilling device and sphygmomanometer technology, applied in boring/drilling, drilling/drilling equipment, metal processing equipment, etc., can solve the problems of high labor intensity, low processing efficiency, affecting processing accuracy, etc. Avoid disassembly and re-clamping, improve production efficiency, suitable for mass production results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

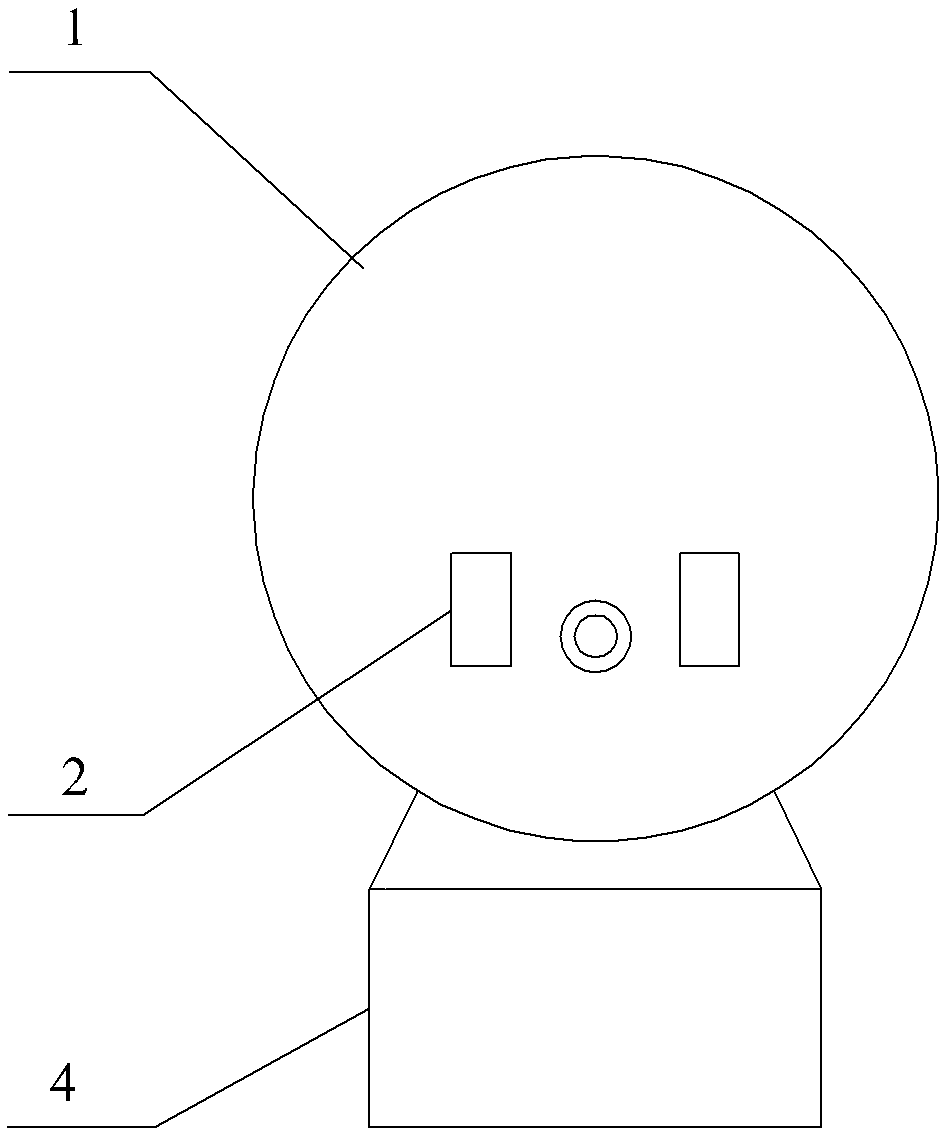

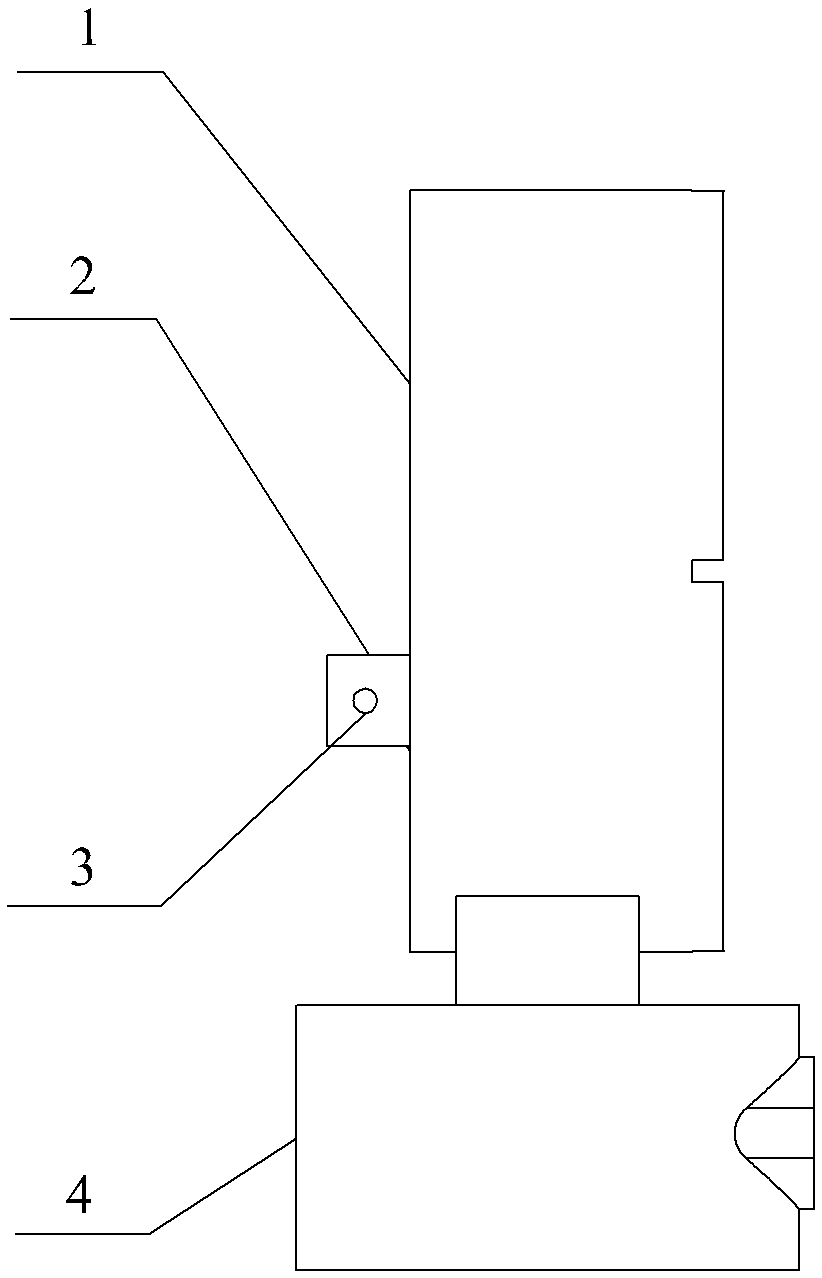

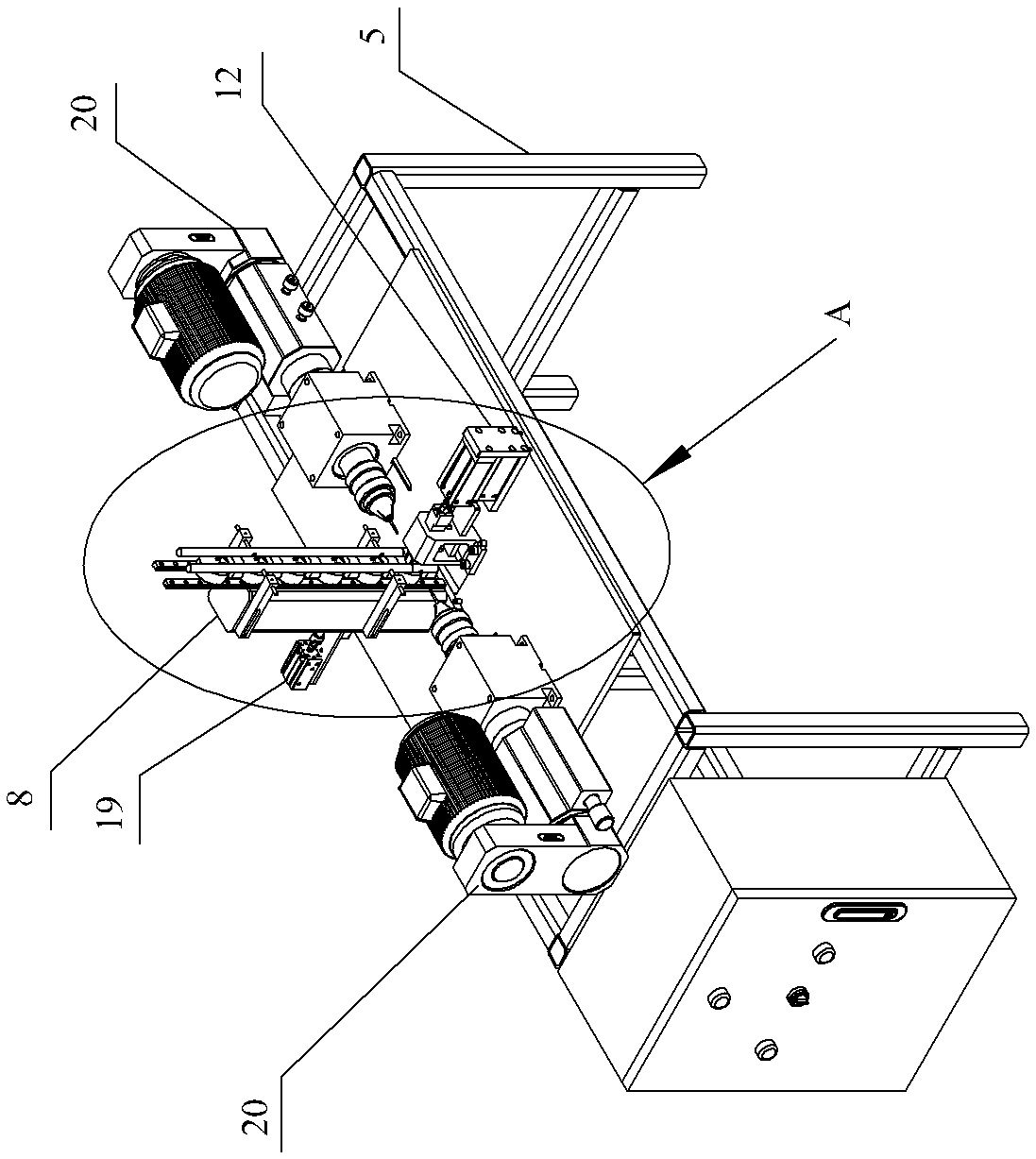

[0017] See Figure 1-7 , a kind of sphygmomanometer case automatic drilling device of the present invention, it comprises frame 5, two drilling machines 20 and PLC control system, the top surface of frame 5 is fixedly connected with support 8, and the front end of support 8 is provided with Vertically arranged workpiece limiting groove, the upper end and the lower end of the workpiece limiting groove are respectively the workpiece inlet and the workpiece outlet. Slide and leave the workpiece limit groove from the workpiece outlet; image 3 Six sphygmomanometer watch cases can be accommodated in the workpiece limiting groove at the same time.

[0018] A guide support frame 11 and a first cylinder fixing bracket 12 are installed in sequence on the frame 5 directly in front of the workpiece limiting groove, and the first cylinder fixing bracket 12 is equipped with a first cylinder 13 and a second cylinder 14 arranged up and down. The first cylinder 13 and the second cylinder 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com