Novel flange connecting structure

A connection structure and flange technology, which is applied to flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of inability to accommodate transition pipes, increase transition pipes, and large space, so as to achieve less space occupation , The structure of the transfer is compact, the effect of convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

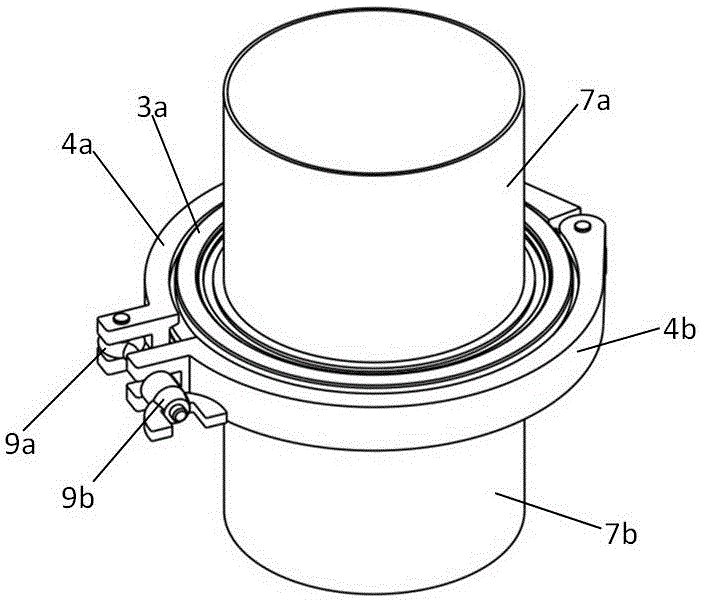

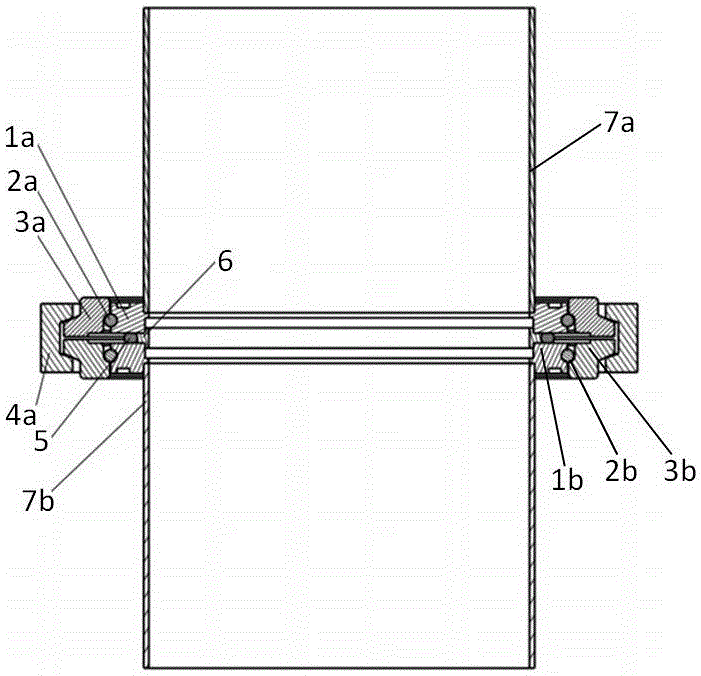

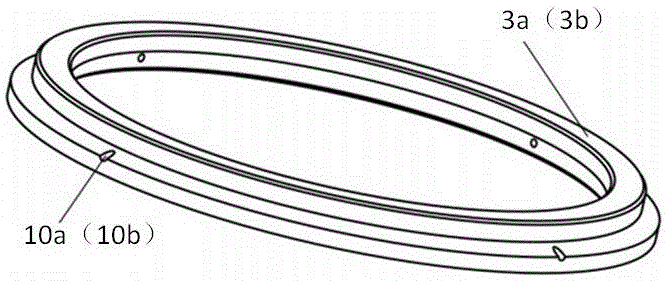

[0029] Such as Figure 1~4 As shown, a novel flange connection structure includes a coaxial upper flange neck 7a and a lower flange neck 7b, and an upper ISO-K vacuum flange 1a is provided at the outer wall of the lower end of the upper flange neck 7a. A lower ISO-K vacuum flange 1b is set on the outer wall of the upper end of the lower flange neck 7b, an upper elastic retaining ring 2a is set on the outer wall of the upper flange neck 7a, and a lower elastic retaining ring is set on the outer wall of the lower flange neck 7b. Ring 2b, the outer wall of the upper ISO-K vacuum flange 1a is provided with an upper looper quick-opening flange 3a, and the outer wall of the lower ISO-K vacuum flange 1b is provided with a lower looper quick-opening flange 3b, so The outer walls of the upper looper quick-opening flange 3a and the lower looper quick-opening flange 3b are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com