Preparation of novel cigarette sweet material and application method thereof

A technology for sweetening materials and cigarettes, applied in applications, tobacco, and e-liquid filter elements, etc., can solve problems such as low sweetness concentration, poor sweetness quality, and obvious side effects, and achieve low raw material costs and simple and easy preparation processes , Improve the effect of aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] Example 1: A preparation method of a new type of cigarette sweetness material, characterized in that the specific steps are as follows: 100g montmorillonite is immersed in a 0.1mol / l hydrochloric acid solution for 2h, and then placed in a shaking bed at 30°C, After shaking at 65r / min for 12h, wash with distilled water to neutrality, filter and dry, put it in a 120℃ oven for 12h; add 30g rebaudioside A, 20g mogroside and 10g methylcyclopentenol Mix the ketones thoroughly; transfer the mixed material to the coating granulator, and add 300g activated carbon for coating granulation. The coating solution is 90g high-fructose syrup with a concentration of 30%; after spraying is completed The material after the coating and granulation process is passed through an 8-mesh sieve to filter out particles with a larger diameter, and then through a 20-mesh sieve to sieve out the unshaped powder, to obtain 452 g of the new cigarette sweetness material.

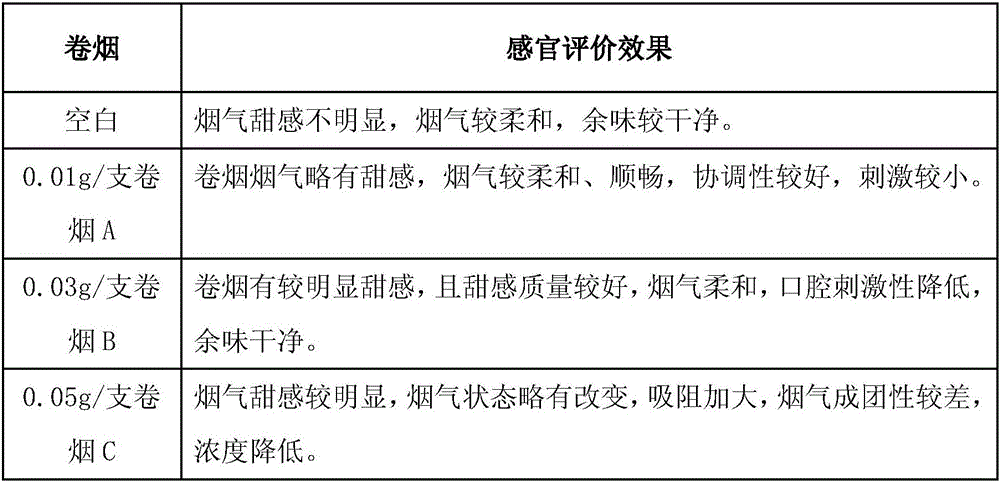

[0014] The new cigarette sweetnes...

Example Embodiment

[0015] Example 2: Put 100g of montmorillonite in a 0.06mol / l hydrochloric acid solution for 3h, then put it in a shaking bed, shake for 8h at 35℃, 70r / min, and wash with distilled water until it is neutral. After suction filtration Dry it and put it in an oven at 130°C for 10 hours; add 40g rebaudioside A, 25g mogroside and 15g methylcyclopentenol ketone, mix well; transfer the mixed material to the coating granulator , Then add 400g of activated carbon to coat and granulate, spray 200g of 40% high fructose syrup aqueous solution as the coating solution; after spraying, pass the coating and granulation process through a 7-mesh screen and filter it out The particles with a larger diameter are then passed through a 30-mesh sieve to remove the unformed powder, and 687 g of the new cigarette sweetness material is obtained.

[0016] The novel cigarette sweetness material prepared in Example 2 was uniformly added to the tow of the mouthpiece during the process of forming the cigarette ...

Example Embodiment

[0017] Example 3: Put 100g of montmorillonite in 0.2mol / l hydrochloric acid solution for 4h, then put it in a shaking bed, shake for 6h at 40℃, 80r / min, wash with distilled water to neutrality, after suction filtration Dry, put in a 150℃ oven and bake for 8 hours; add 20g rebaudioside A, 30g mogroside and 5g methylcyclopentenol ketone, mix well; transfer the mixed material to the coating granulator , And then add 160g of activated carbon for coating and granulation. The coating solution is 50g of high-fructose syrup solution with a concentration of 20%; after spraying, the material after the coating and granulation process is passed through a 10 mesh screen and filtered out The particles with a larger diameter are then sieved through a 40-mesh sieve to remove the unshaped powder to obtain 317 g of the new cigarette sweetness material.

[0018] The new cigarette sweetness material prepared in Example 3 was uniformly added to the tow of the mouthpiece during the process of forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com