Sweet profile modified neotame sweetener suitable for tipping paper for cigarettes as well as preparation method and application of sweet profile modified neotame sweetener

A technology of tipping paper and sweetener for cigarettes, applied in the application, special paper, tobacco and other directions, can solve the problems of strong oral sweetness, poor coordination of smoke, influence, etc., to improve oral sweetness and aftertaste comfort The effect of enhancing the sweetness of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present disclosure provides a preparation method of a sweet profile modified neotame sweetener suitable for cigarette tipping paper, comprising the following steps:

[0034] Disperse the additive in the ethanol-water system at a temperature of 60-85°C, then add neotame under stirring and continue stirring for a period of time, and then make a powder to obtain a sweetness profile modified neotame sweetener, wherein , the additive is at least one of cyclodextrin, sodium carboxymethylcellulose, sodium alginate, guar gum, agar, carrageenan, mannitol and maltitol, and the sweetness profile modified neotame sweetener The mass percentage of neotame is 40.55-70.85%, and the mass percentage of the additive is 29.15-59.45%.

[0035] The purpose of continuing to stir after adding neotame to the system is to fully disperse and dissolve neotame, and the stirring time can be flexibly selected according to actual needs, which is not further limited in this disclosure.

[0036] In...

Embodiment 1

[0048] Raw materials include neotame, cyclodextrin, sodium carboxymethylcellulose and mannitol, the mass percentage of neotame is 45.00%, and the total mass percentage of cyclodextrin, sodium carboxymethylcellulose and mannitol is 55%, the mass ratio of cyclodextrin, sodium carboxymethylcellulose and mannitol is 2:4:4.

[0049] Disperse cyclodextrin, sodium carboxymethylcellulose and mannitol in the ethanol-water system (volume ratio 3:7), set the temperature of the system at 80°C, slowly add neotame to it under stirring, and continue stirring to disperse uniform, and then adopt the method of spray drying to obtain the sweetness profile modified neotame sweetener.

[0050] Dissolving and dispersing the sweetness profile modified neotame sweetener in the tipping paper varnish, and transferring it to the base paper of the tipping paper through gravure printing and other processes to obtain the sweetness tipping paper I, the content of neotame on the tipping paper It was 206.5 μ...

Embodiment 2

[0052] The raw materials include neotame, guar gum and mannitol, the mass percentage of neotame is 55.00%, the total mass percentage of guar gum and mannitol is 45%, and the mass percentage of guar gum and mannitol is The ratio is 3:7.

[0053] Disperse guar gum and mannitol in the ethanol-water system (volume ratio is 2:8), set the system temperature to 70°C, slowly add neotame to it while stirring, continue to stir and disperse evenly, and then spray Drying method to obtain sweetness profile modified neotame sweetener.

[0054] The sweetness profile modified neotame sweetener is dissolved and dispersed in the tipping paper varnish, and transferred to the base paper of the tipping paper through gravure printing and other processes to obtain the sweetness tipping paper II, the content of neotame on the tipping paper It was 235.4 μg / g.

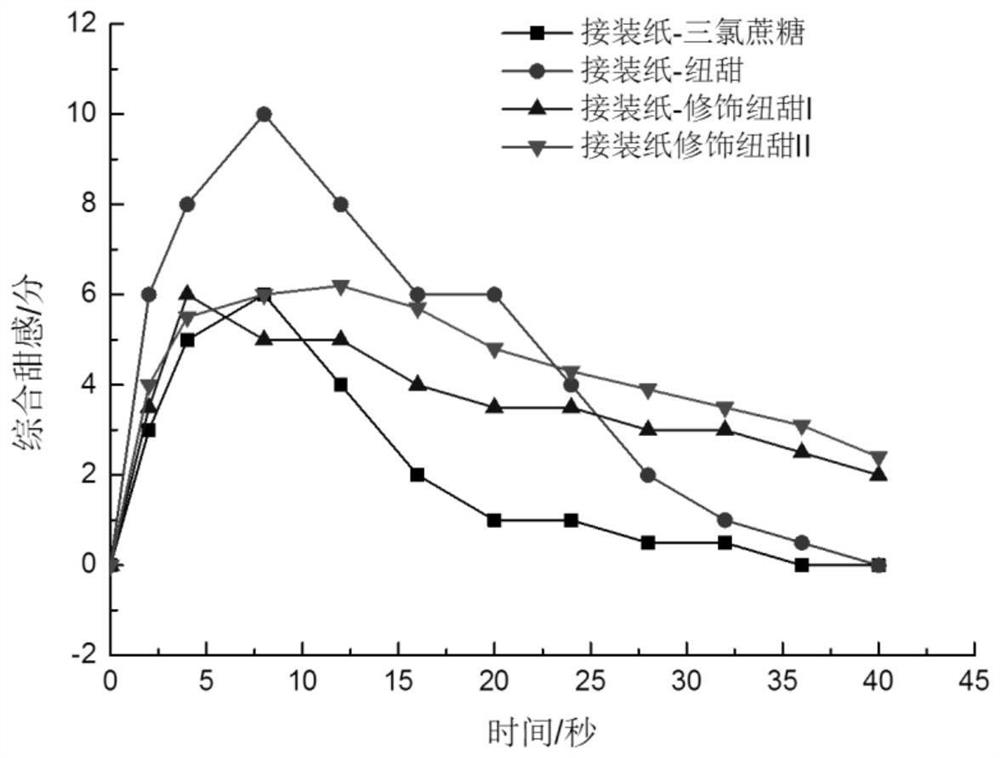

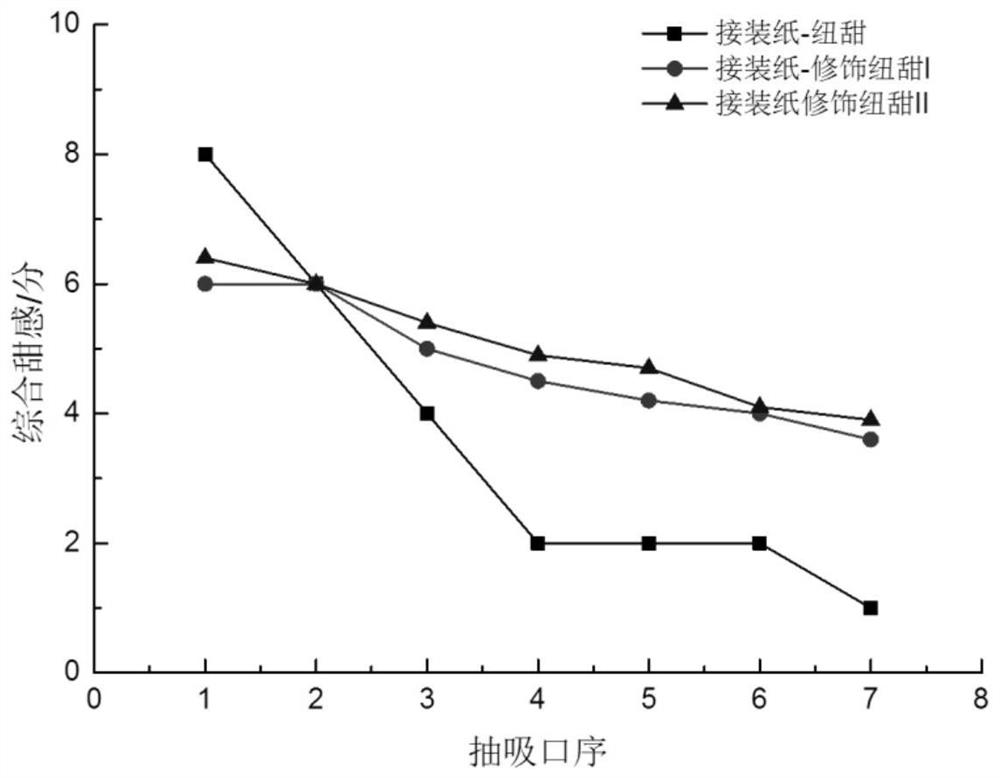

[0055] Using the cigarette sensory evaluation method, comprehensively evaluate the sweetness of the smoke and the aftertaste in the mouth. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com