An intelligent warehouse roadway robot manipulator

A technology of intelligent warehousing and manipulators, which is applied to conveyor objects, transportation and packaging, storage devices, etc., and can solve the problems of insufficient in-position accuracy, slow response, and unstable grasping of goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

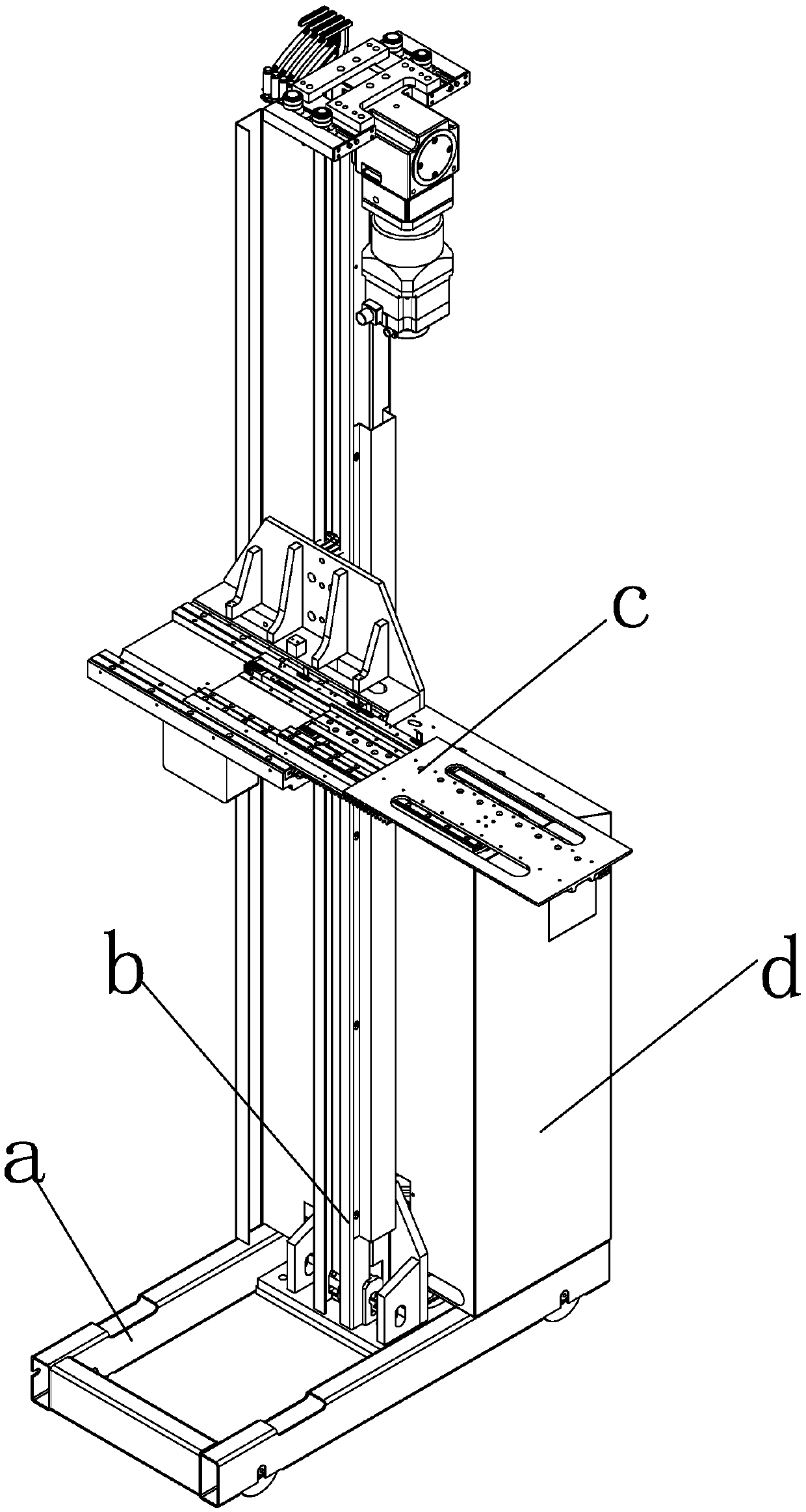

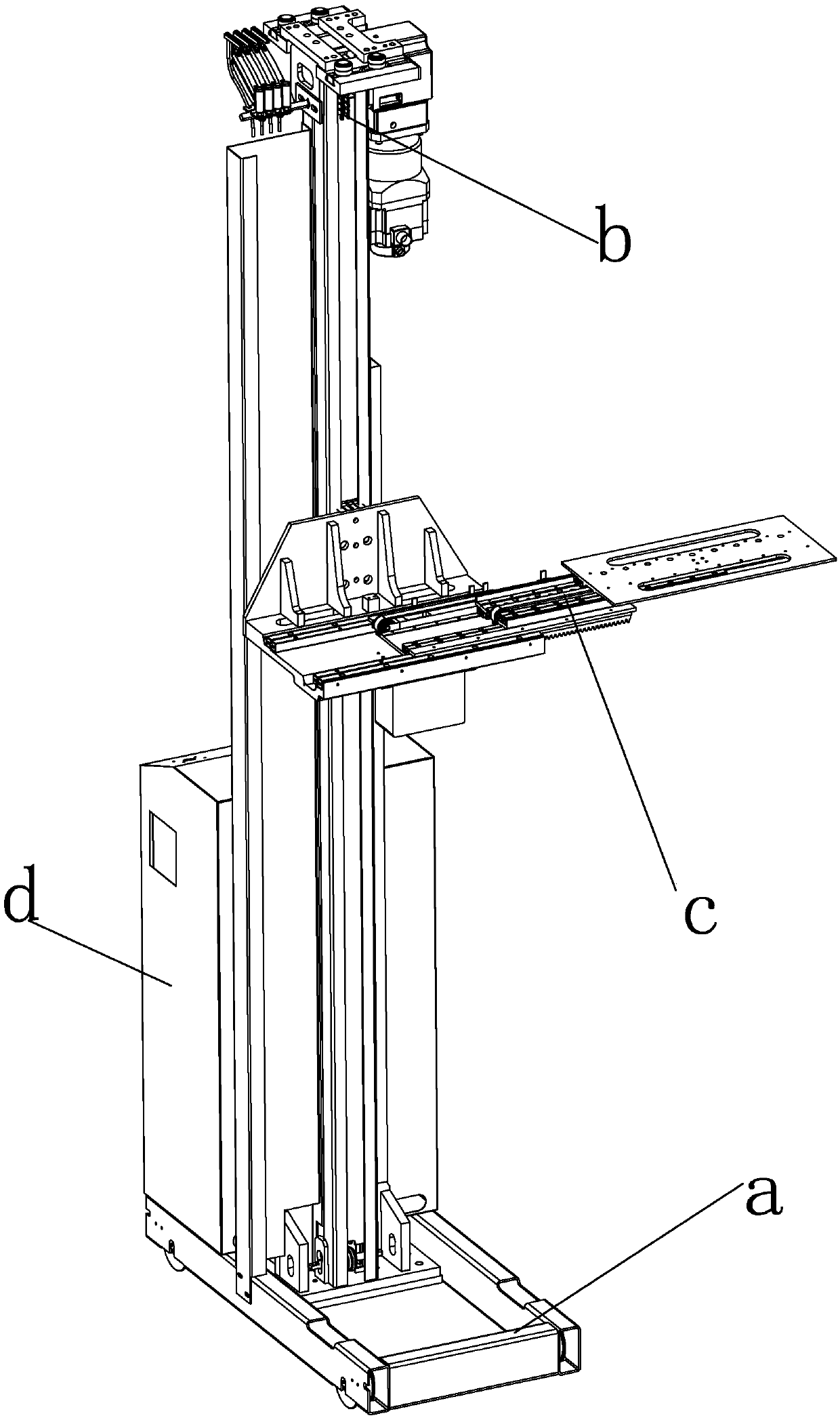

[0024] see Figures 1 to 2 , the intelligent storage roadway robot manipulator provided in this embodiment is set on the intelligent storage roadway robot (specifically, installed on the vertical lifting mechanism of the intelligent storage roadway robot) through the support mounting plate. Wherein, the intelligent warehouse roadway robot includes a horizontal moving mechanism a, a vertical lifting mechanism b, a manipulator c and an industrial computer control system power distribution cabinet d.

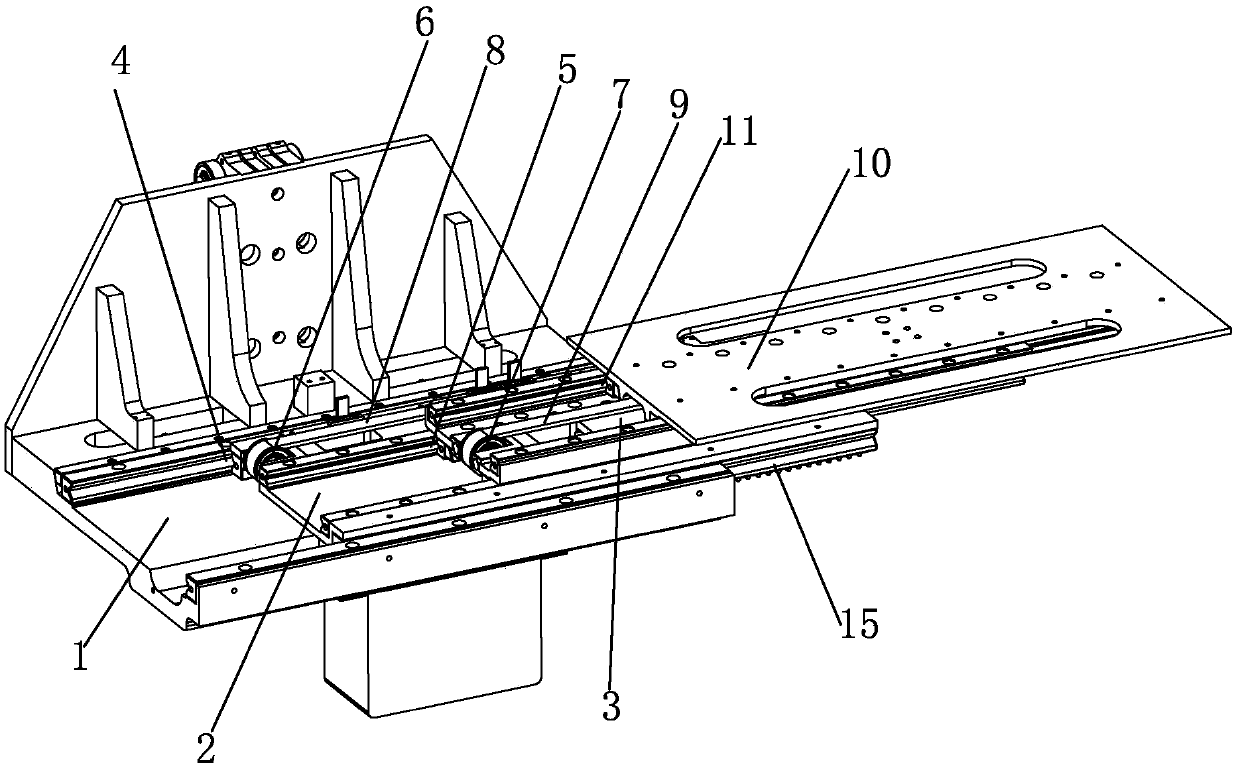

[0025] see Figures 3 to 7 , an intelligent storage roadway robot manipulator, including a driving device, a plate base 1, a first transition plate 2, a second transition plate 3, a first transition plate guide rail 4, a second transition plate guide rail 5, a first transition plate synchronous wheel set 6, The second transition plate synchronous wheel set 7, the first transition plate synchronous belt 8, the second transition plate synchronous belt 9, the fork plate 10, the fork ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com