Devices, transmissions and universal mechanical couplings for forces of different magnitudes and directions

A transmission and coupling technology, applied in the direction of transmission, mechanical equipment, engine components, etc., can solve problems such as instability and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

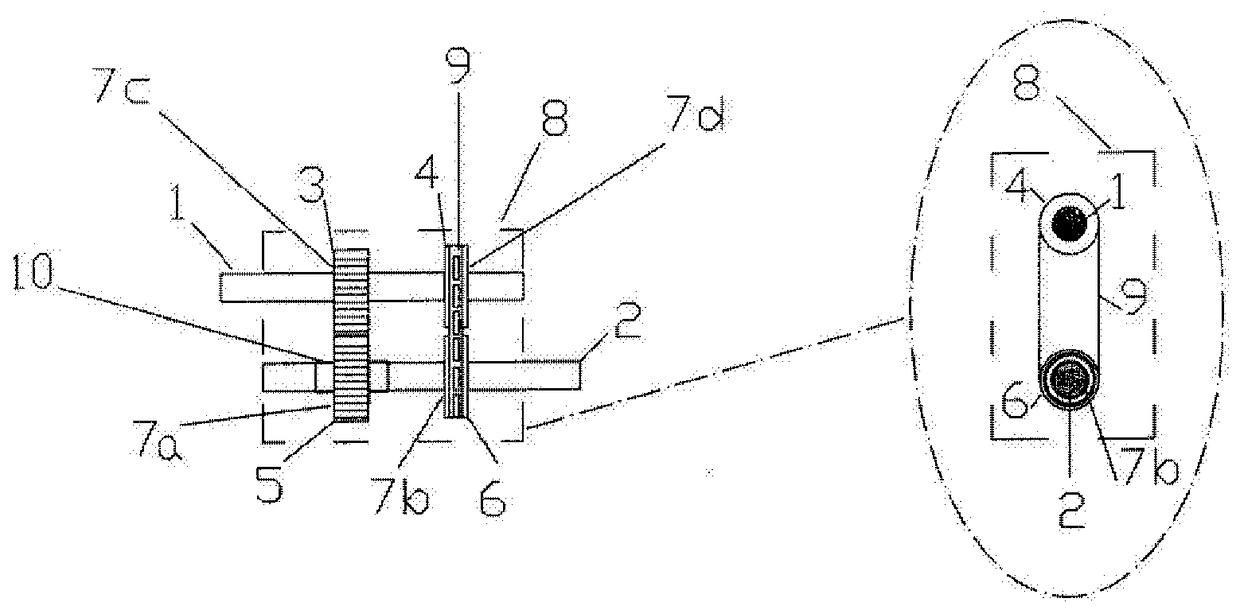

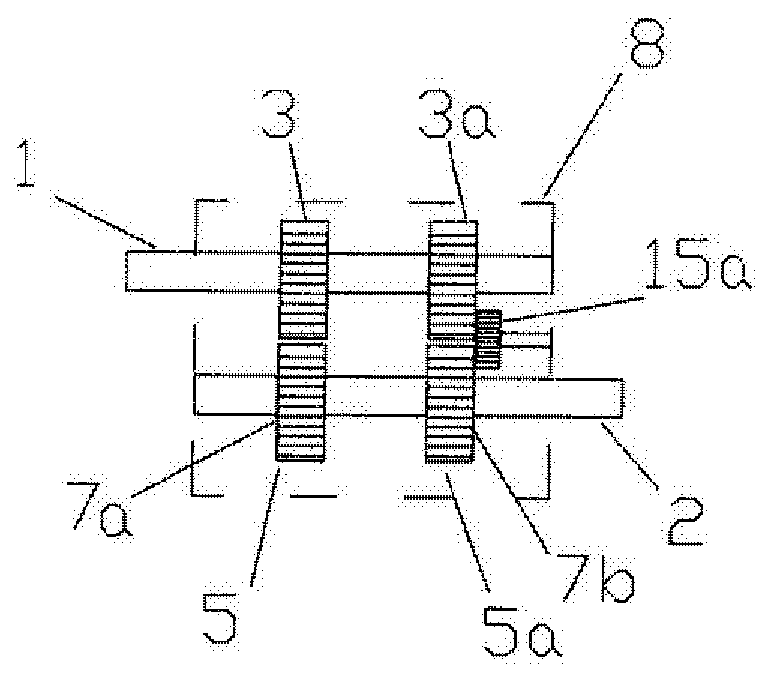

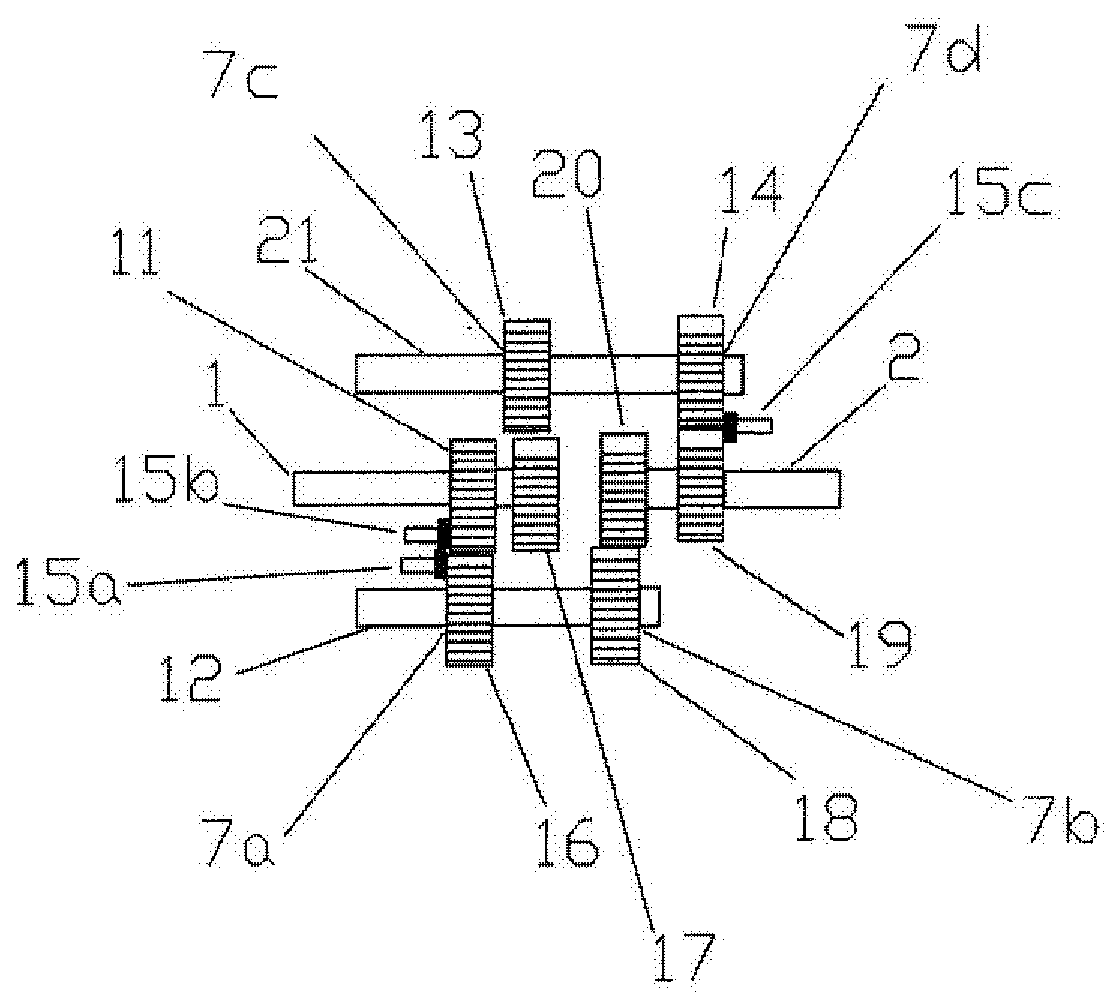

[0021] Example Description ( figure 1 )

[0022] This example shows the most basic way of forming an object. This consists of constructing the coupling unit by a hybrid connection between the two shafts 1 , 2 without using a rotary inverter.

[0023] From the input shaft 1 to the output shaft 2 are placed transmission devices 3 and 5 and transmission devices 4 , 9 and 6 .

[0024] For further details on this embodiment: two elements are placed in the input shaft 1 suitable for transmitting the motion occurring in said shaft 1, in this case the cog 3 or gear, and at the minimum required distance A pulley or another cog or pinion 4 is located on the input shaft 1 .

[0025] A cog 5 and another cog with pinion 6 are placed on the output shaft 2 to which a rotary or one-way drive is coupled, in this case by two free wheels 7a and 7b Institutional composition. These unidirectional rotary or drive mechanisms 7a and 7b are placed so that they both exert a force on the shaft on w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com