Gas Sensors and Sensor Devices

A gas sensor and gas technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of increased power consumption of the detection circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

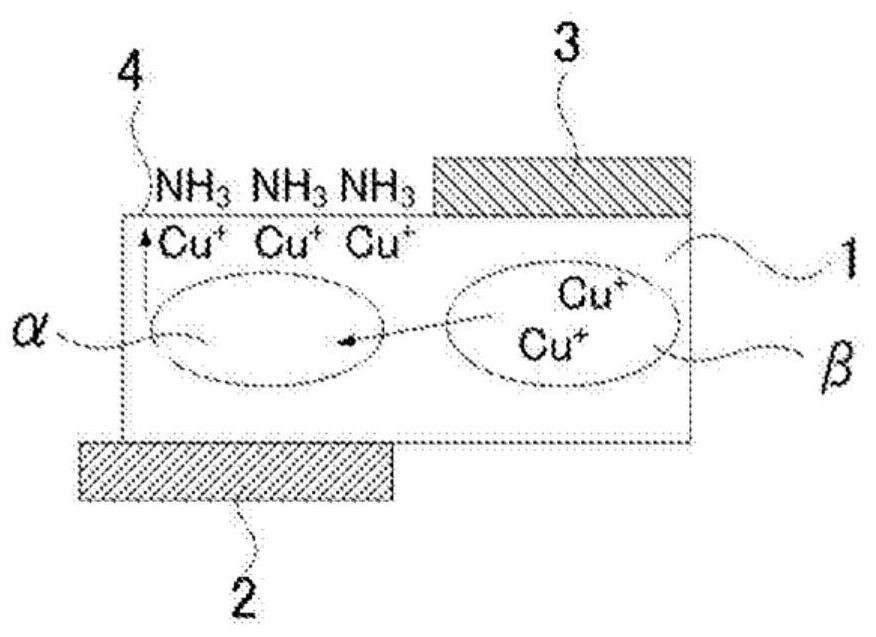

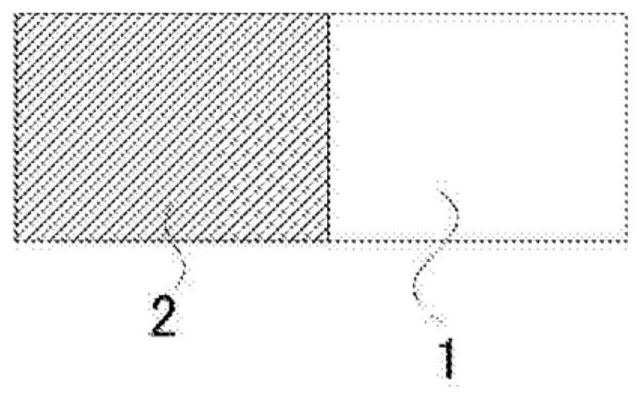

[0145] made as Figure 6A ~ Figure 6C The gas sensor shown. Specifically, the above-mentioned gas sensor was produced by the following method.

[0146]

[0147] A gold electrode (first electrode 2) with a width of 10 mm x a length of 25 mm x an average thickness of 30 nm was formed by vacuum evaporation on a silicon wafer with a thermal oxide film having an average thickness of 1 μm and a width of 12 mm x a length of 50 mm x a thickness of 0.6 mm.

[0148]

[0149] A copper layer having a width of 8 mm×length of 30 mm×an average thickness of 0.5 μm was formed using a vacuum deposition method so as to cover part of the first electrode 2 . Next, by the same method as described in "2. Experimental" of the literature (Pascal Lauque, Marc Bendahan, Jean-Luc Seguin, Kieu An Ngo, Philippe Knauth, Analytica Chimica Acta, 515, (2004), 279-284) Method A copper bromide aqueous solution was used to convert the copper in the copper layer into cuprous bromide to obtain a solid electro...

Embodiment 2

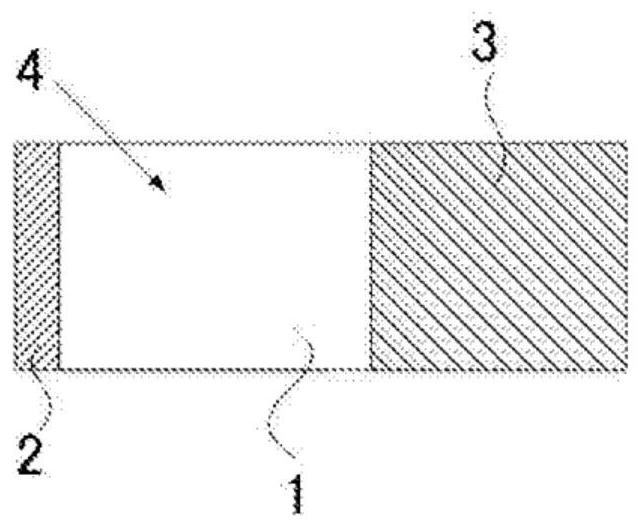

[0158] made as Figure 8A ~ Figure 8C The gas sensor shown. Specifically, the above-mentioned gas sensor was produced by the following method.

[0159]

[0160] A gold electrode (first electrode 2) with a width of 10 mm x a length of 20 mm x an average thickness of 60 nm was formed by vacuum evaporation on a silicon wafer with a thermal oxide film having an average thickness of 1 μm and a width of 12 mm x a length of 50 mm x a thickness of 0.6 mm.

[0161]

[0162] Cuprous bromide (solid electrolyte layer 1 ) of width 8 mm×length 30 mm×average thickness 200 nm was formed using radio frequency magnetron sputtering (RF magnetron sputtering) so as to cover part of the first electrode 2 .

[0163] The conditions of the radio frequency magnetron sputtering method are as follows.

[0164] ·RF power: 100W

[0165] · Sputtering gas: Ar

[0166] Sputtering gas: flow rate 30sccm

[0167] ·Air pressure: 0.5Pa

[0168]

[0169] Furthermore, if Figure 8A As shown, a gold elec...

Embodiment 3

[0179] made as Figure 10 The gas sensor shown. Specifically, the above-mentioned gas sensor was produced by the following method.

[0180]

[0181] Use vacuum evaporation method to form 2 gold electrodes (the first electrode 12 and the first electrode 12 and second electrode 13). The above-mentioned two gold electrodes were provided with a gap of 1 mm between opposing end portions.

[0182]

[0183] A copper layer having a width of 8 mm x a length of 30 mm x an average thickness of 0.5 μm was formed on the above two gold electrodes using a vacuum evaporation method. Next, by the same method as described in "2. Experimental" of the literature (Pascal Lauque, Marc Bendahan, Jean-Luc Seguin, Kieu AnNgo, Philippe Knauth, Analytica Chimica Acta, 515, (2004), 279-284) Method A copper bromide aqueous solution was used to change the copper in the above copper layer to cuprous bromide to fabricate a solid electrolyte layer 11 and obtain a sample.

[0184]

[0185] A copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com