Chemical mechanical polishing device and method

A chemical machinery and polishing device technology, applied in grinding devices, grinding/polishing equipment, grinding machine tools, etc., can solve the problems of low accuracy of polishing layer thickness, large errors, and reduced measurement precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Hereinafter, a chemical mechanical polishing device 9 according to an embodiment of the present invention and a polishing head 100 used in the chemical mechanical polishing device 9 will be described in detail with reference to the accompanying drawings. However, in describing the present invention, in order to clarify the gist of the present invention, a detailed description of known functions or structures will be omitted.

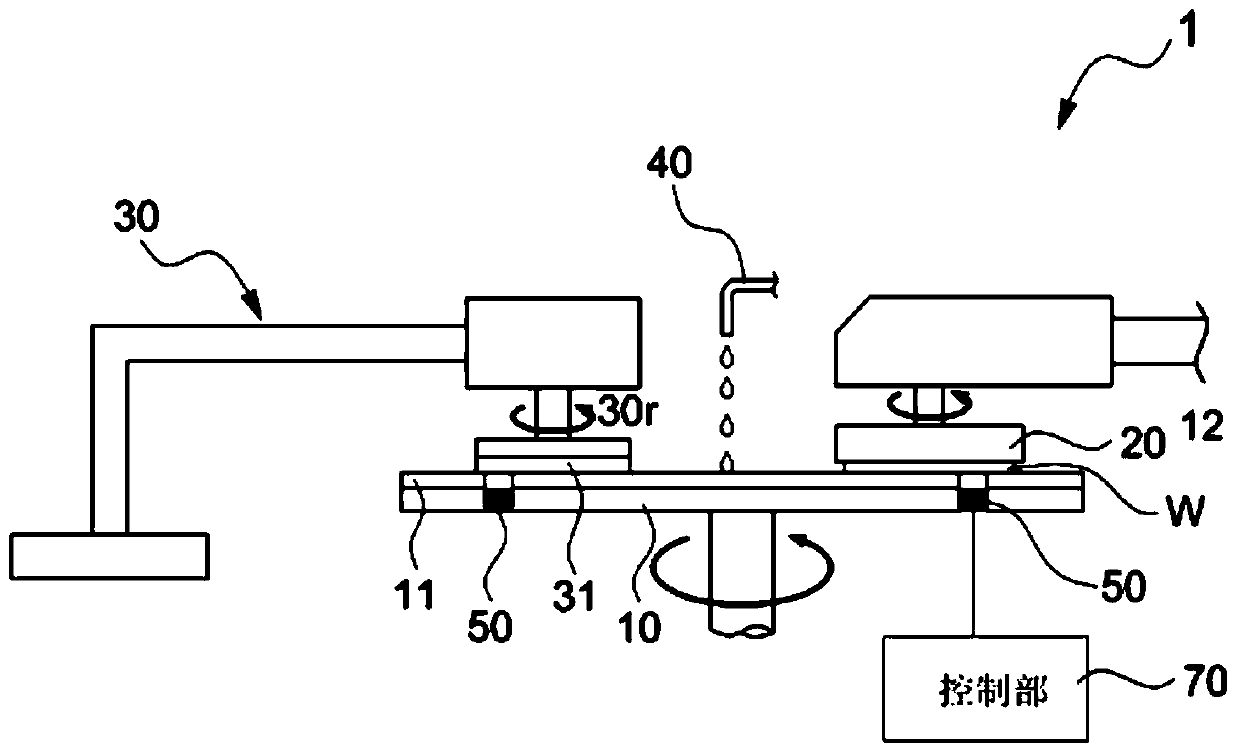

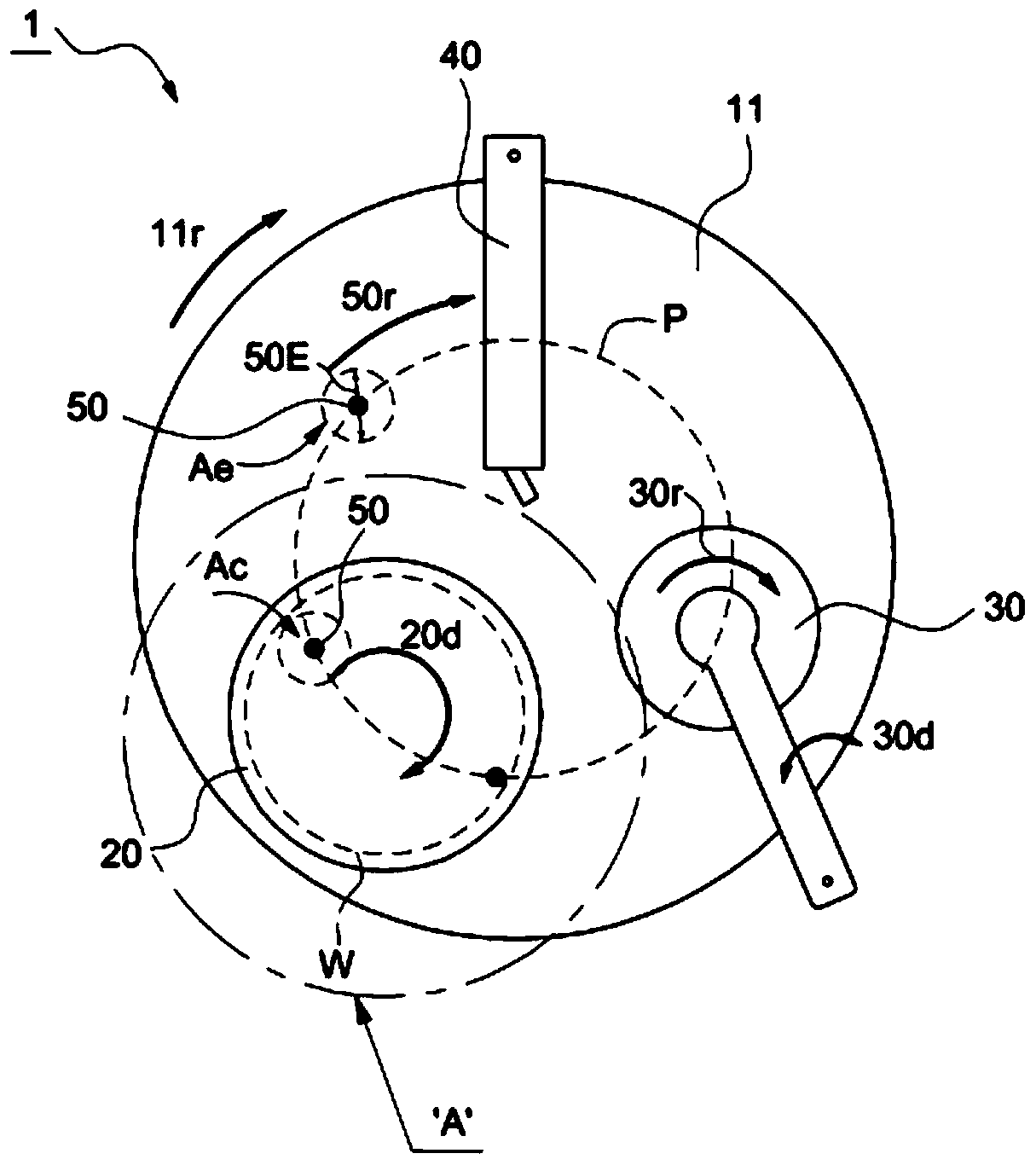

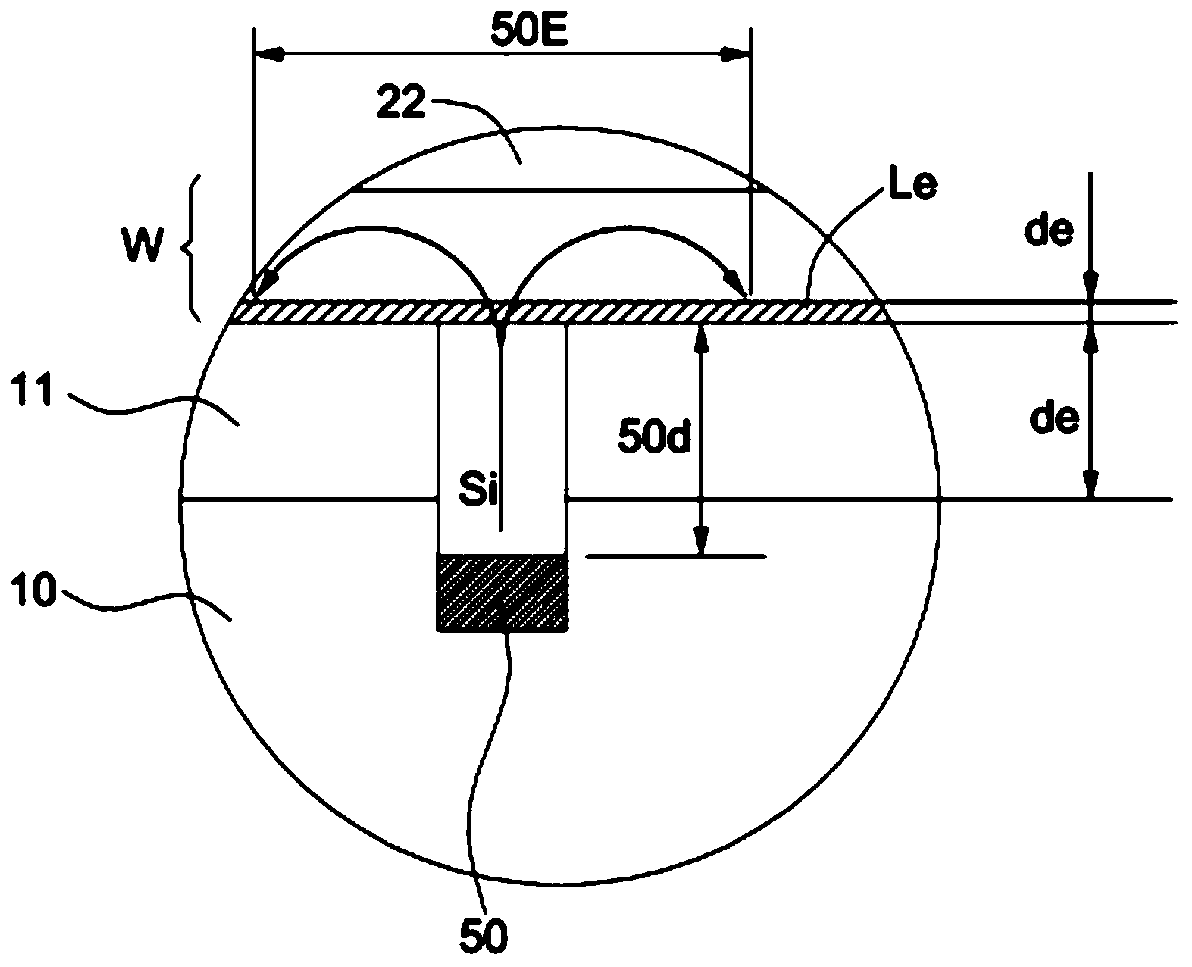

[0071] A chemical mechanical polishing device 9 according to an embodiment of the present invention includes: a polishing plate 10 covered by a polishing pad 11 that contacts the polishing surface of the wafer W; , and make the wafer W rotate; the eddy current sensor 50 applies an eddy current to detect the thickness of the polishing layer of the wafer W and receives an output signal from the polishing layer; and the control unit 90 applies an alternating current to the eddy current sensor 50, and from The output signal received by the eddy curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com