Capacitor vapor deposition negative pressure gold plating device and gold plating method

A vapor deposition and capacitor technology, which is applied in the direction of capacitors, capacitor manufacturing, laminated capacitors, etc., can solve the problems of limited spray gun coverage, long travel of conductive materials, and changes, so as to achieve better molding effects, improve electrical conductivity, and shape The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

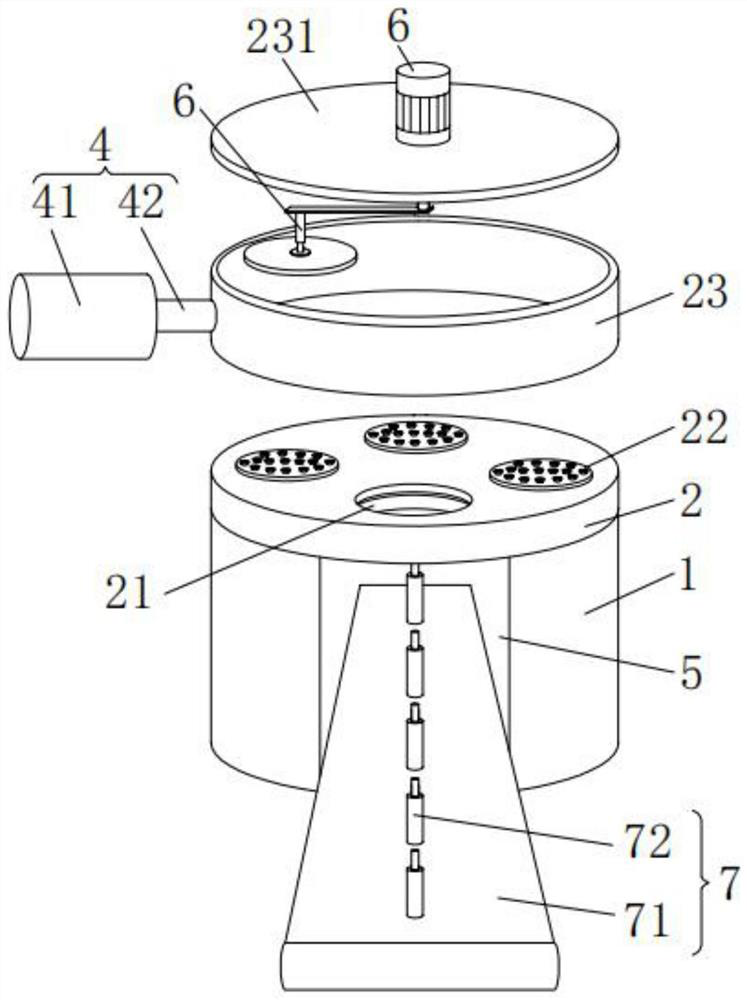

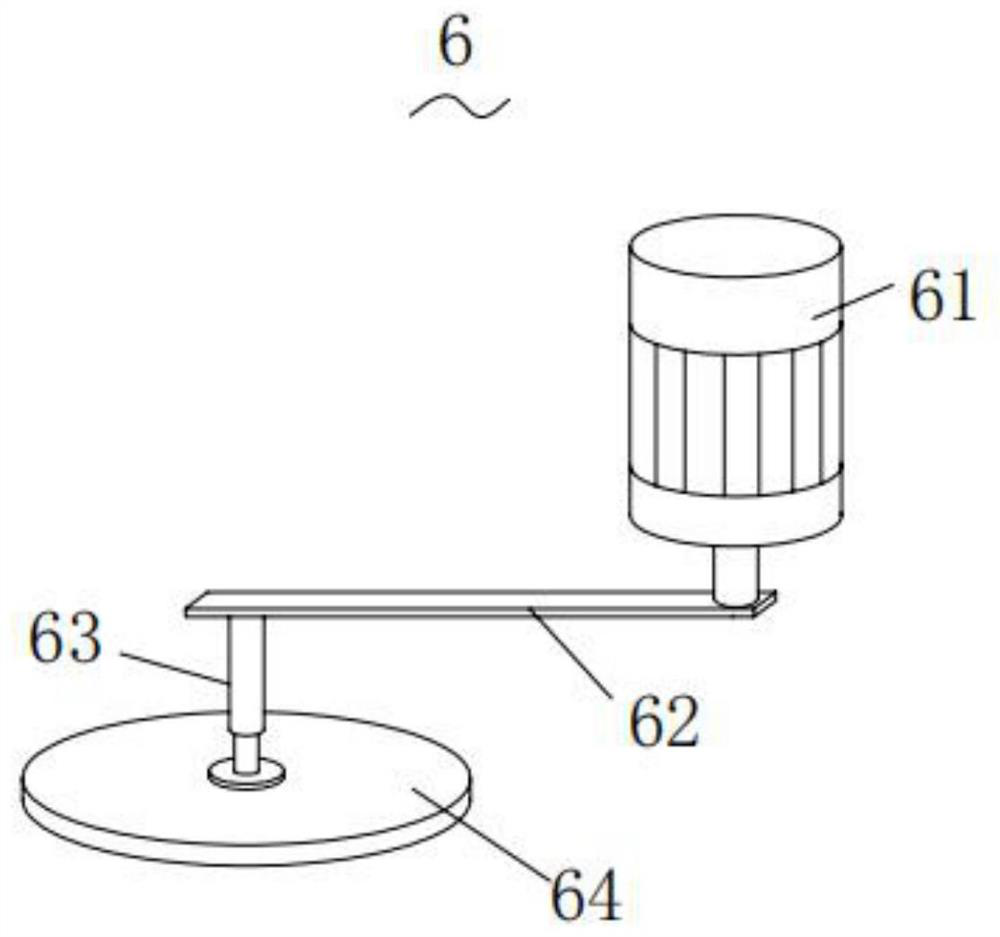

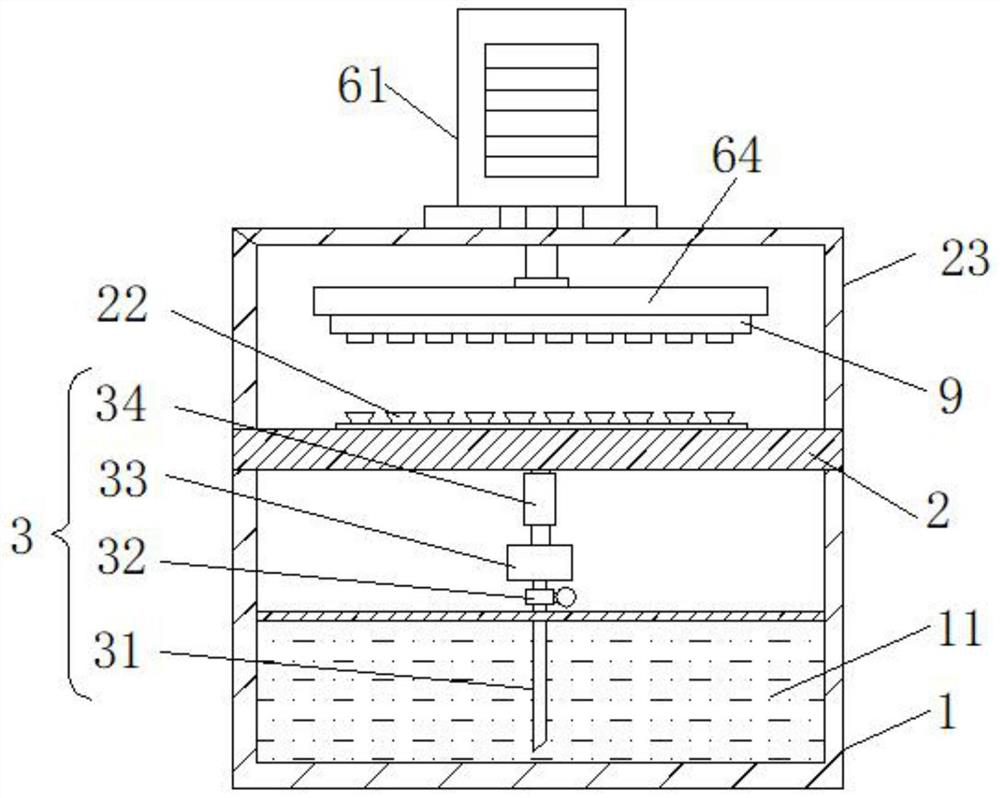

[0042]The capacitor vapor deposition negative pressure gold plating device includes a tank body 1; the inner bottom of the tank body 1 is provided with a molten material storage chamber 11 with a sealed structure; the top of the tank body 1 is provided with a circular hollow structure operating seat 2, The surface of the operating seat 2 is provided with a sealing cover 23; the outside of the sealing cover 23 is connected to a vacuum mechanism 4; the sealing cover 23 is a processing area for depositing gold plating, and the vacuum mechanism 4 is used to pump the inside of the sealing cover 23 to a vacuum state;

[0043] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com