Motor-car propelling type ejector

A catapult, propulsion technology, applied in the direction of launch/drag transmission, etc., can solve the problems of difficult control, pressure drop, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

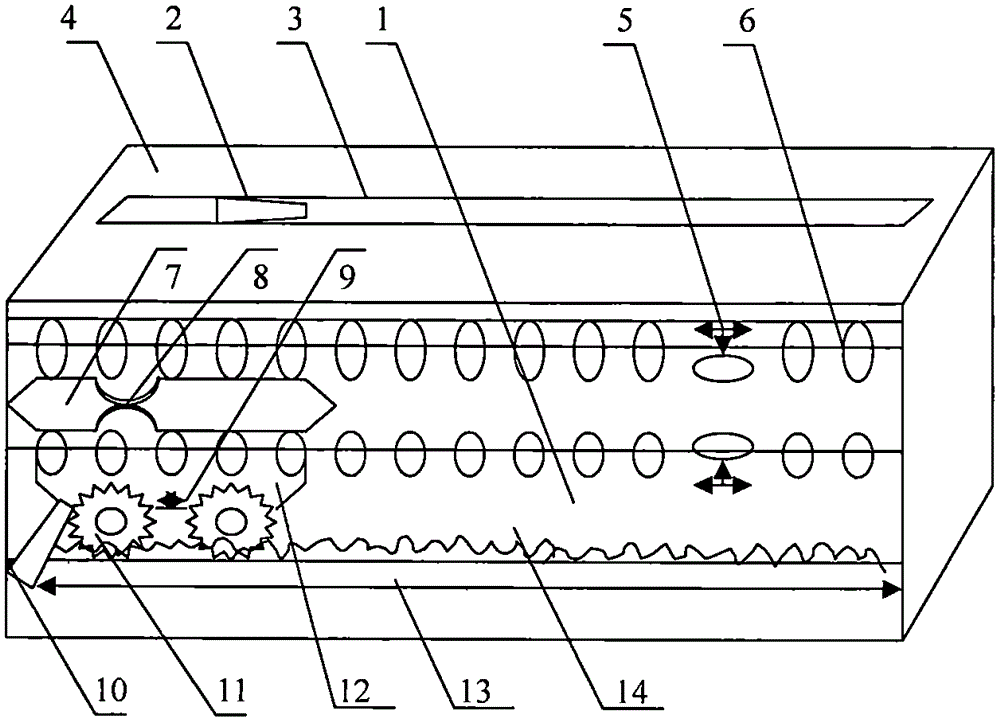

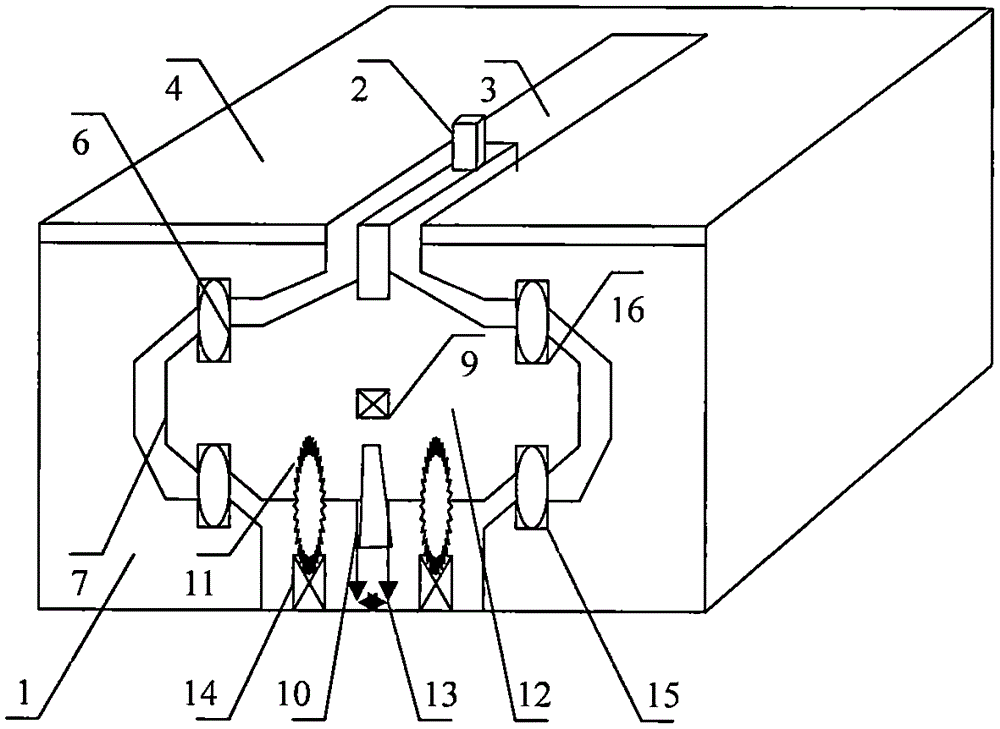

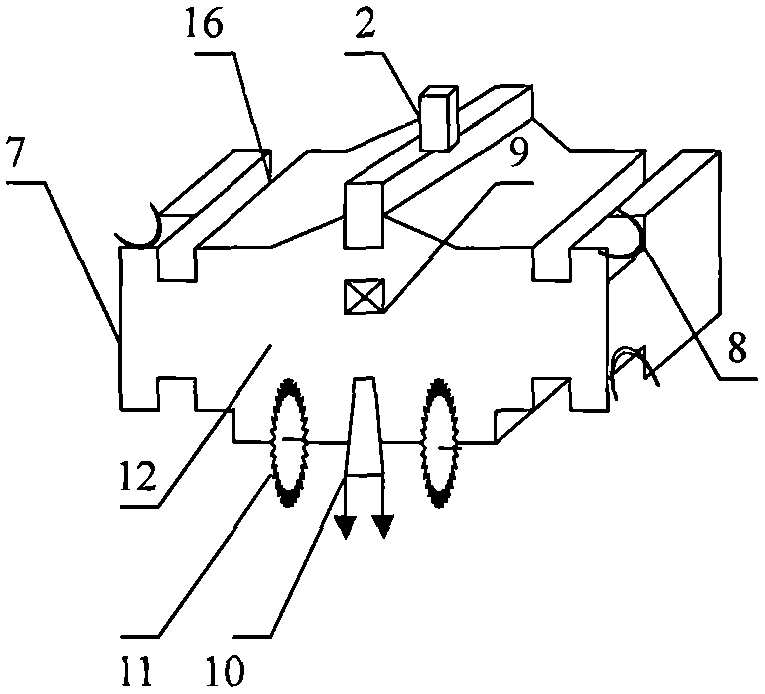

[0021] figure 1 As shown in the propulsion type catapult of a motor vehicle, an ejection chamber 1 is set in the hull, and two sets of sliding wheels 6 and brakes 5 are arranged in the ceiling and wall panels on both sides of the ejection chamber 1. The runway deck 4 is set, and the pulley groove 3 is set in the runway deck 4; two motor car tracks 14 with gear teeth are arranged on the bottom plate of the ejection chamber 1, and the horizontal lines of the teeth on the two motor car tracks 14 must be kept absolutely aligned with each other On a horizontal line, a motor car 12 is set on the motor car track 14, and a motor wheel 11 is arranged in the motor car 12: a sliding wing plate 7 is set on the motor car 12, and a brake hole 8 is set in the front and back of the sliding wing plate 7, and the sliding wing The plate 7 is arranged in the middle of the sliding wheel 6, the motor 9 is arranged in the motor car 12, the pantograph 10 is arranged at the rear end of the motor car 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com