A non-metallic aerodynamic structural surface static test loading device

A static test and loading device technology, applied in the test field, can solve problems such as easy collapse, large error, and influence on the surface strength of the test piece

Inactive Publication Date: 2011-11-30

CHINA AIR TO AIR MISSILE INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the aerodynamic structural surface of non-metallic materials such as composite materials does not allow any damage to it, it cannot be used

Second, if the method of pasting the canvas sheet is adopted, it will affect the surface strength of the specimen, and the test cannot be completed in most cases

Its disadvantages are: the load distribution system is unstable and easy to collapse; when the stress surface is deformed

, the error between the load value transmitted by the force rod 2 and the theoretical value is large

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

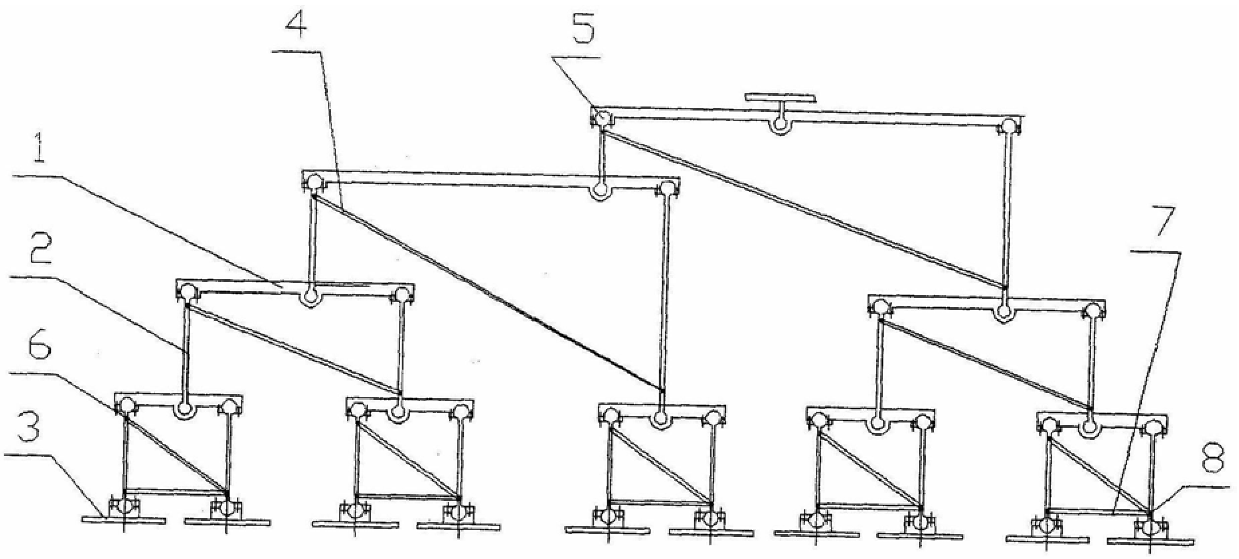

[0011] The present invention will be described in further detail below. See Figure 1, a non-metallic aerodynamic structure surface static test plus

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

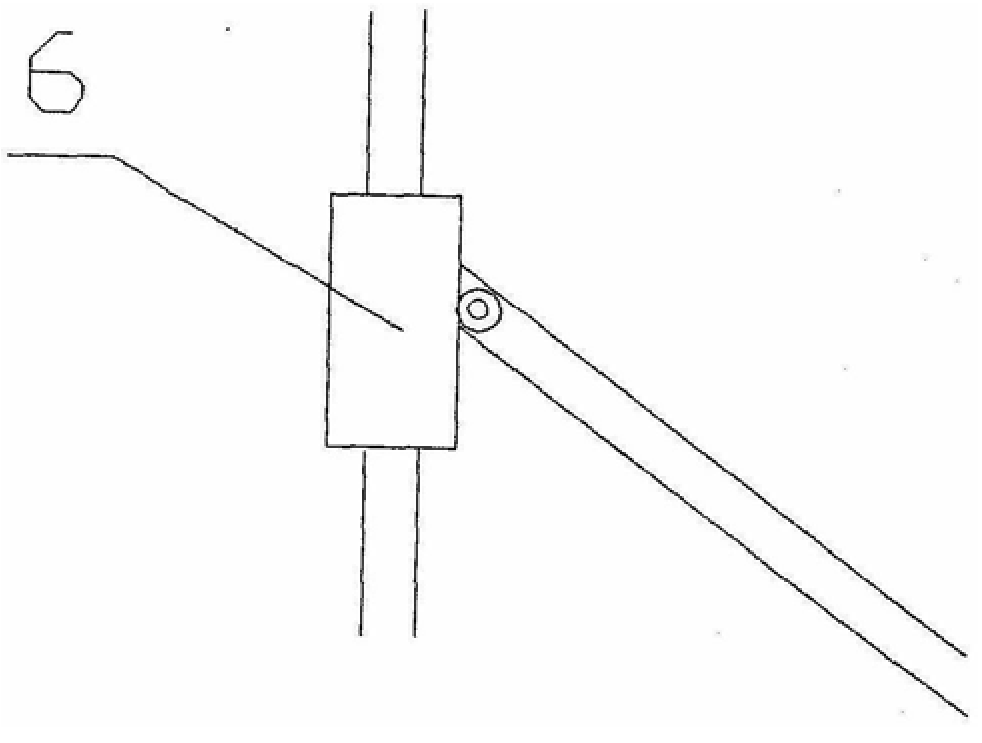

The invention relates to a non-metallic aerodynamic structural surface static test loading device, which belongs to the test technology and relates to the improvement of the aircraft aerodynamic structural surface static test loading device. Including a load distribution system composed of multi-stage load distribution mechanism, characterized in that the force rod [2] and the load distribution beam [1] in the load distributor of each level of load distribution mechanism pass through the universal ball joint [5 ] connection; there is a diagonal stay rod [4] between the two application rods [2] of the load distribution mechanism of the load distribution mechanism at each level, and there are two application rods [2] for each load distribution mechanism in the first-stage load distribution mechanism ] There is a tie rod [7] between the lower end. The invention is suitable for performing static tests on small non-metal structural surfaces, does not cause any damage to the aerodynamic structural surfaces, has a stable load distribution system, and can accurately apply loads to the tested pieces.

Description

A non-metallic aerodynamic structural surface static test loading device Technical field The invention belongs to test technology, relates to the improvement of the static test loading device of aircraft aerodynamic structure surface. Background technique For various aerodynamic structural surfaces, it is necessary to carry out various test loading assessments, determine its bearing capacity situation, assessment Whether it meets the design requirements. For the aerodynamic structural surface with large structural size, the test clips are generally tested by means of tension and compression. Set up and conduct tests. However, for the structural surface of small structural size, if it is a metal part, it is generally used to punch on the test surface. The test fixtures are arranged in the form of holes, and the multi-point distributed load strength assessment of structural parts can be carried out by using the multi-level lever composite effect test. None of the abov...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/08G01N3/04

Inventor 王宏伟臧其昌何辉

Owner CHINA AIR TO AIR MISSILE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com