Helicopter undercarriage loading device

A loading device and landing gear technology, which is applied in the direction of measuring devices, aircraft component testing, mechanical component testing, etc., can solve the problems of difficult upward loading, unsatisfactory design effect, and complicated bench structure, etc., so as to achieve easy installation, Strong practicability, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the present invention in detail and to facilitate the understanding of those skilled in the art, specific implementations of the present invention will be described in conjunction with the accompanying drawings.

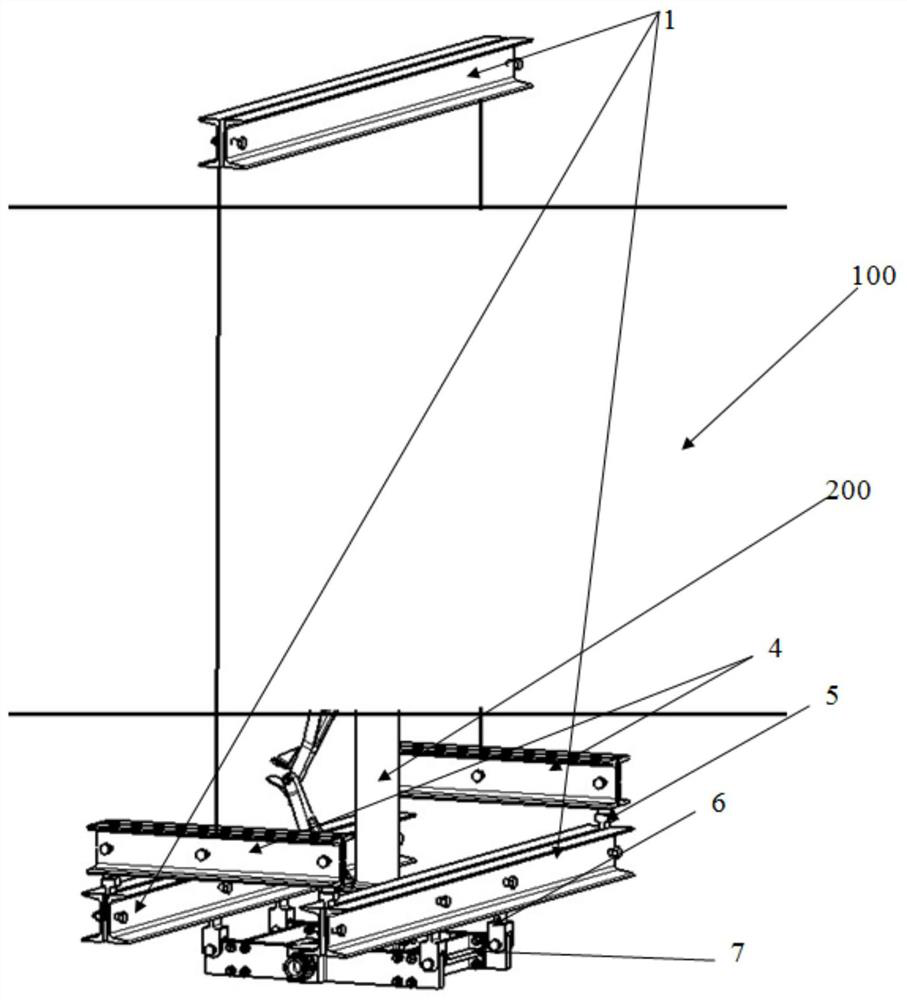

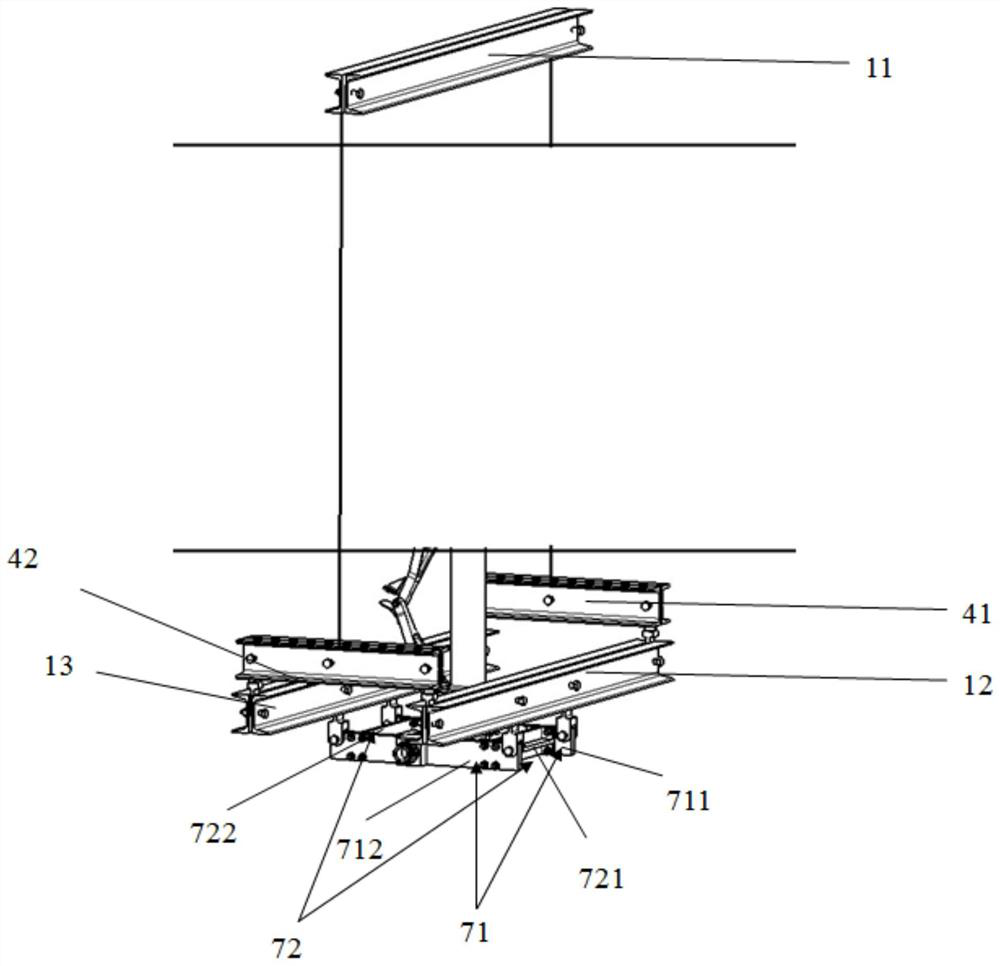

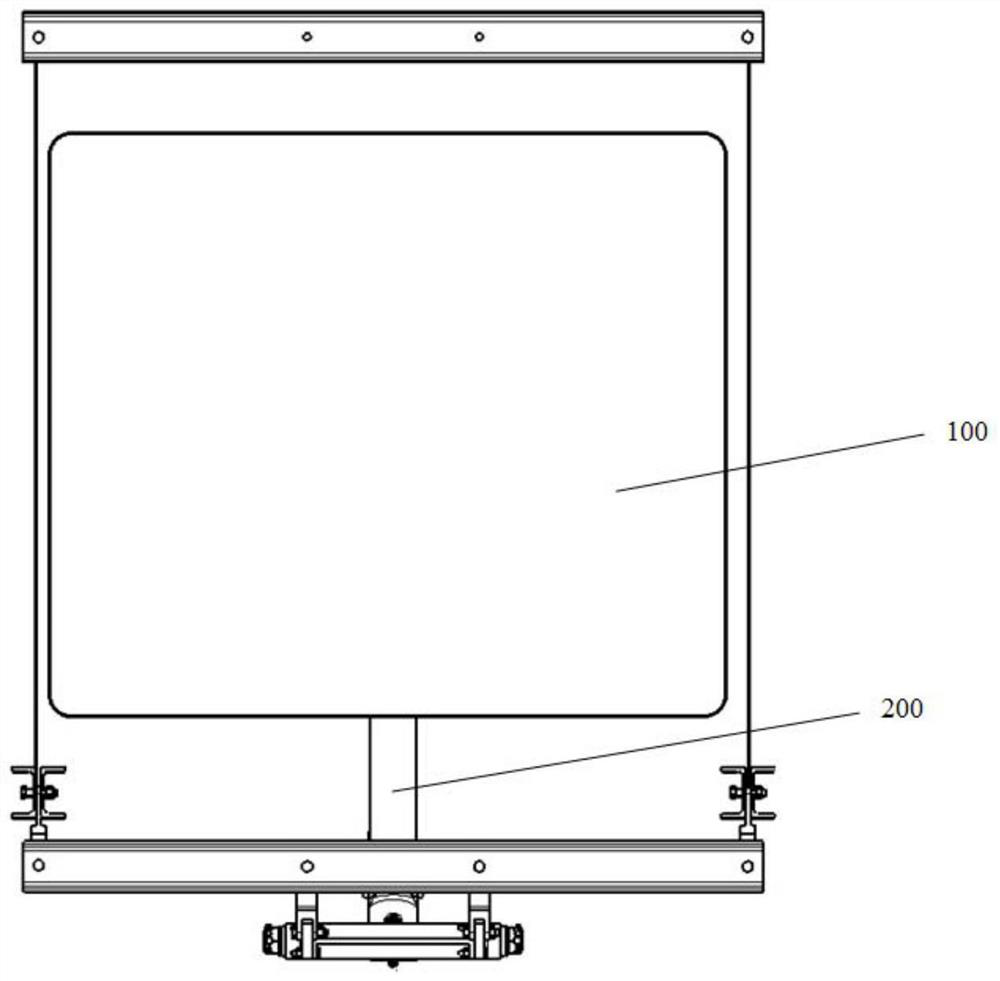

[0028] Such as Figure 1-4 Shown, a kind of helicopter landing gear loading device is used for carrying out loading test to helicopter landing gear test piece, and described helicopter landing gear test piece comprises fuselage frame 100, landing gear 200, and the position of described landing gear 200 is positioned at the machine. The lower part of the body frame 100 is characterized in that the loading device includes a long lever assembly 1, a connecting cable 2, a short lever assembly 4, a first adapter 5, a second adapter 6, and a wheel support assembly 7;

[0029] The long lever assembly 1 includes an upper long lever 11, a lower front long lever 12, and a lower rear long lever 13 arranged in parallel up and down along the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com