A method and device for monitoring the gas path performance of a gas turbine

A technology of gas turbine and gas circuit, which is applied in the direction of internal combustion engine testing, etc., can solve problems such as inability to effectively detect gas circuit faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

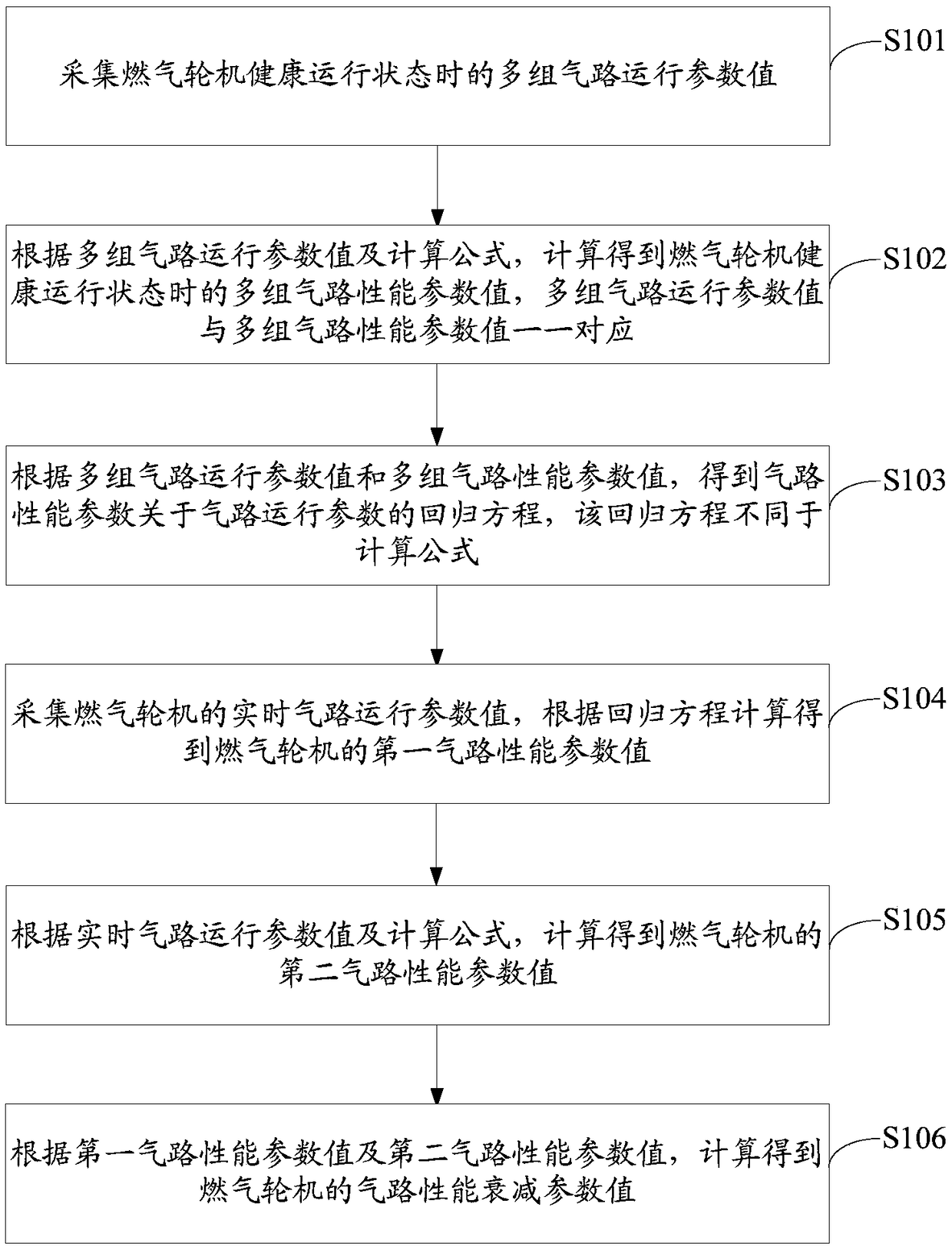

[0095] This embodiment provides a method for monitoring the gas path performance of a gas turbine, such as figure 1 As shown, steps S101, S102, S103, S104, S105 and S106 are included. Each step is described in detail below.

[0096] Step S101: Collect multiple sets of gas path operating parameter values when the gas turbine is in a healthy operating state.

[0097] Gas path operating parameters include data directly measured by sensors installed on various components of the gas turbine, or parameters that cannot be directly measured but can be directly measured by sensors and obtained after a basic calculation. Specifically, the operating parameters of the gas circuit may include ambient temperature, ambient pressure, gas generator compressor inlet temperature, gas generator compressor outlet temperature, gas generator compressor inlet pressure, gas generator compressor outlet pressure, gas generator Compressor rotor speed, gas generator turbine inlet temperature, gas gene...

Embodiment 2

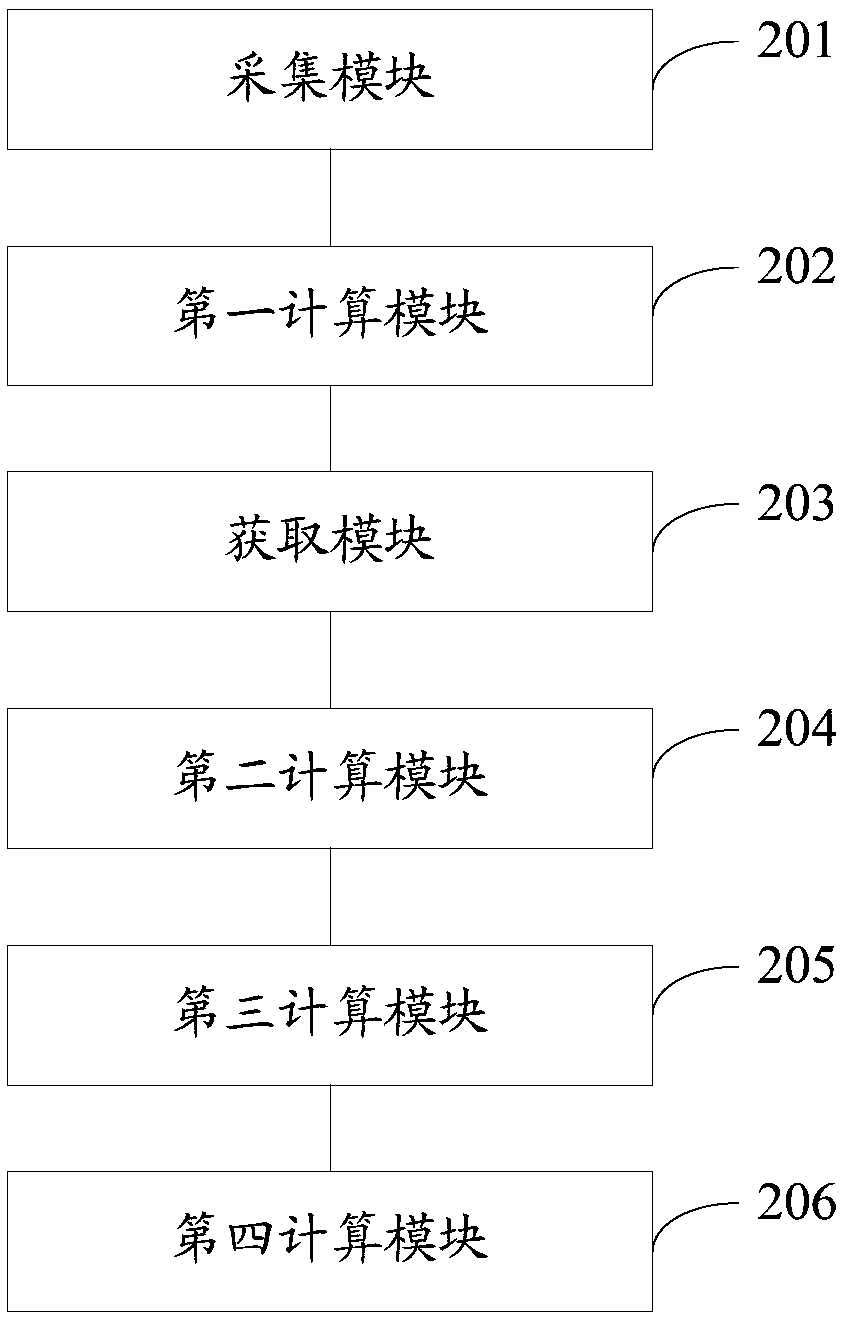

[0277] Corresponding to Embodiment 1, this embodiment provides a device for monitoring the gas path performance of a gas turbine, such as figure 2 As shown, it includes a collection module 201 , a first calculation module 202 , an acquisition module 203 , a second calculation module 204 , a third calculation module 205 and a fourth calculation module 206 . Each module is introduced in detail below.

[0278] The collection module 201 is used to collect multiple groups of gas circuit operation parameter values when the gas turbine is in a healthy operation state.

[0279] The gas circuit operating parameters collected by the collection module 201 include data directly measured by sensors installed on various components of the gas turbine, or parameters that cannot be directly measured but can be directly measured by sensors after a basic calculation. Specifically, the operating parameters of the gas path include ambient temperature, ambient pressure, gas generator compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com