Multi-sensor counting device and counting method for detecting concave plate-shaped objects

A multi-sensor, counting device technology, applied in counting mechanisms/objects, instruments, etc., can solve the problems of inability to meet the counting requirements of full concave or convex concave mixed glass, undercounting or overcounting, and missing counting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

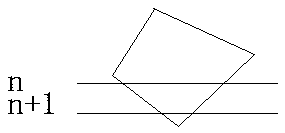

[0051] In the present invention, the definition of a convex plate is: the upper surface of the plate is orthographically projected, and the connection line between any two points in the planar figure obtained after the orthographic projection is all located on the planar figure. The definition of a concave plate is: the upper surface of the plate is orthographically projected, and there are at least two points in the plane figure obtained after the orthographic projection, and the connection line between these two points is not completely located The plate on the plane figure.

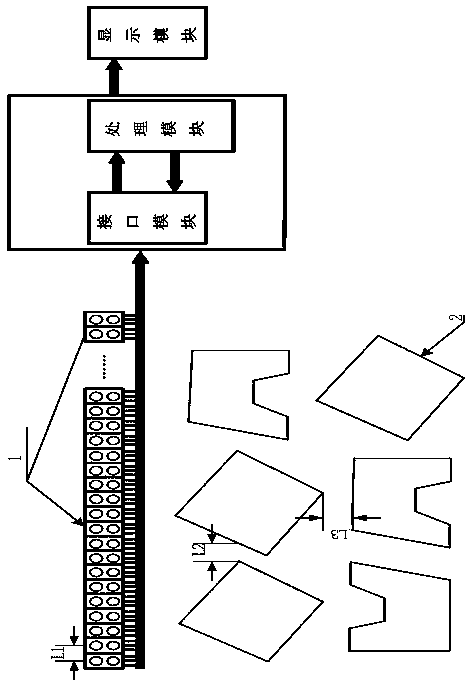

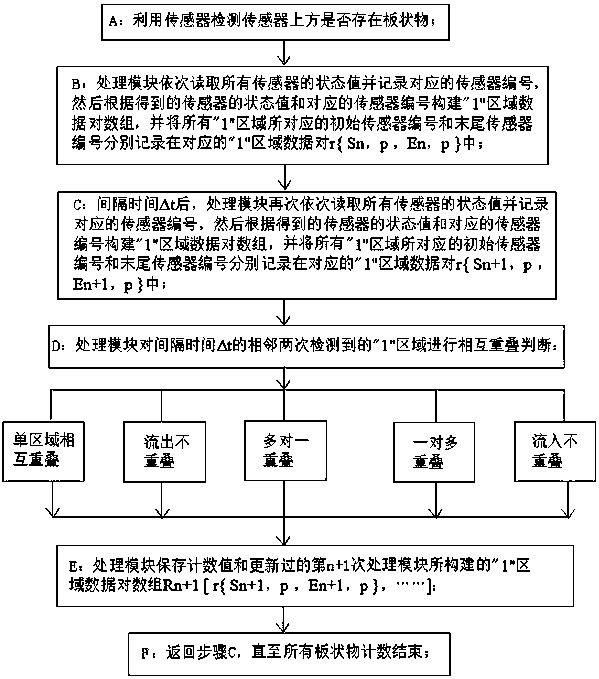

[0052] Such as figure 1 As shown, the multi-sensor counting device for detecting concave plate-like objects according to the present invention includes a processing module, an interface module and a plurality of sensors;

[0053] A plurality of sensors are evenly spaced under the plate conveying device, and in the sensor array composed of a plurality of sensors, the numbers from the first sensor to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com