Task box based batch material management system and method

A technology of management system and management method, applied in resources, logistics, data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

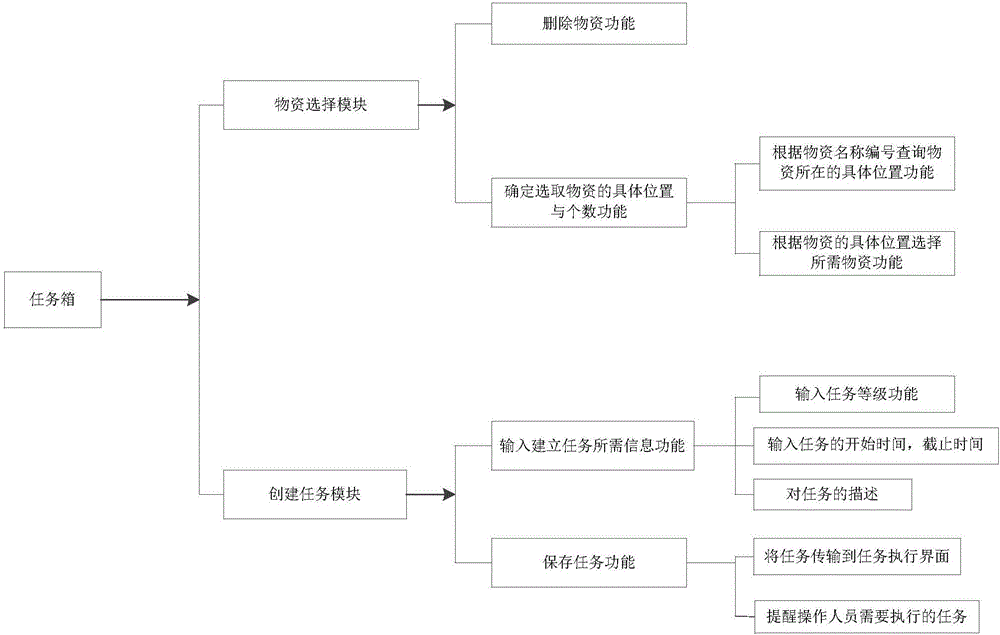

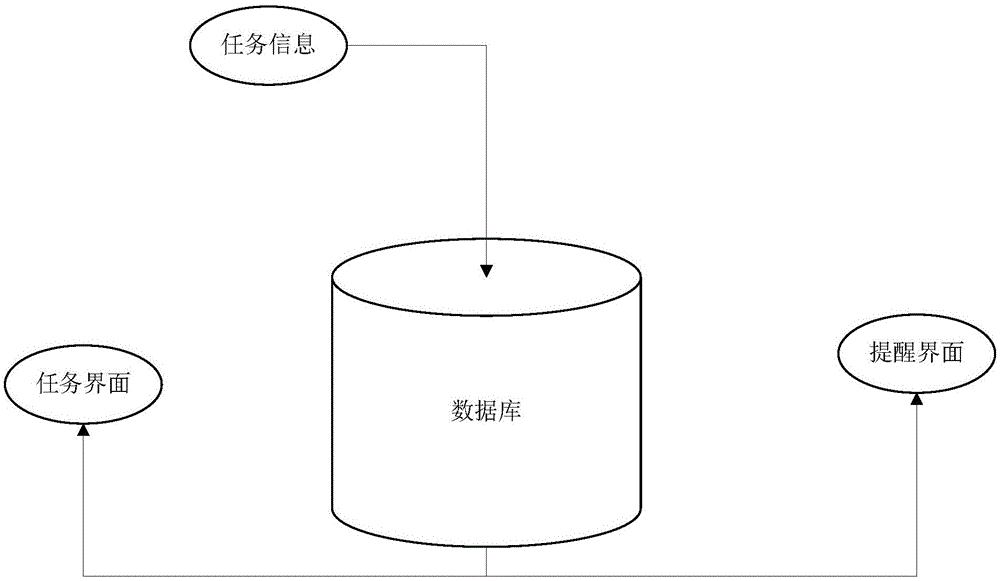

[0049] like Figure 1 to Figure 3 As shown, according to an embodiment of the present invention, this embodiment discloses a batch material management system based on a task box, which changes the way of material selection, proposes the concept of a task box, and uses the task box as an intermediate buffer area, thereby A two-tier architecture for material selection is realized. The task box has two forms: one is to provide a unified task box to save all the optional materials. The other is to provide multiple task boxes, each task box corresponds to a type of task, and saves the alternative materials that need to be processed for this type of task.

[0050] Specifically, when there is only one task box, the system includes: a task box for storing all the candidate materials; the task box includes: a material selection module and a task creation module; wherein, the material selection module, It is used to complete the function of selecting materials in the inventory; the ta...

Embodiment 2

[0062] According to another embodiment of the present invention, the difference between the batch material management system based on the task box in this embodiment and the above-mentioned first embodiment is only that multiple task boxes are provided, each task box corresponds to a type of task, and the task of this type is saved. Alternative supplies to be processed. Each task box material selection module and task creation module; wherein, the material selection module is used to complete the selection function of materials in the inventory; specifically, it includes two function points of deleting materials and determining the specific location and number of selected materials. The task creation module is used to complete the task creation function for the selected materials, and specifically includes two function points of inputting the information required for the specific task and saving the task.

[0063] The implementation of the batch material management system base...

Embodiment 3

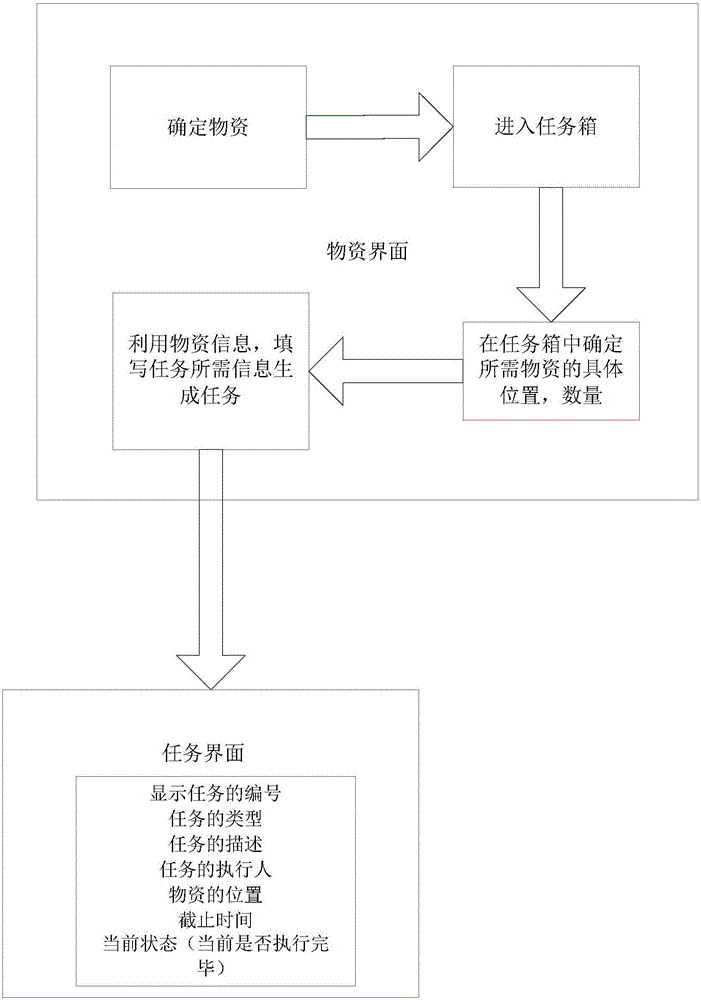

[0065] like Figure 4 As shown, according to another embodiment of the present invention, this embodiment discloses a batch material management method based on a task box, and the method is aimed at a situation where there is only one task box. Specifically, the batch material management method based on the task box includes the following steps:

[0066] Step 1. Enter the material selection interface, which is used to present the selected material. In order to realize the preliminary screening of the required materials, a search function is added to this interface. Enter the name or number of the required material in the set search bar, click Search, and the interface displays the material related to the information entered in the search.

[0067] Step 2. On the material selection interface, select the material to be managed and put it into the task box.

[0068] Step 3. After the material selection is completed, enter the task box.

[0069] Step 4. If there are materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com