Capacitance monitoring device and monitoring method for magnetorheological suspension sedimentation process

A magnetorheological fluid, capacitance monitoring technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of low measurement accuracy, inability to realize real-time measurement, and inability to achieve disturbance, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

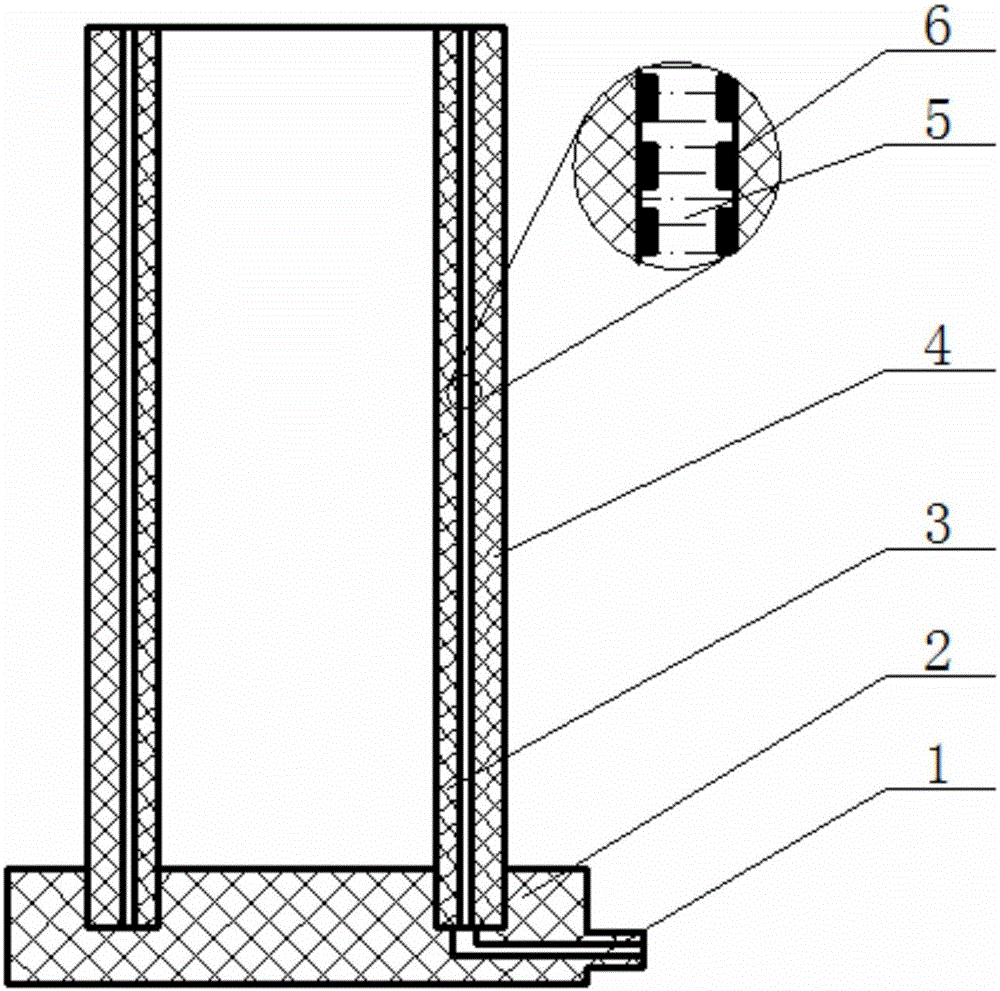

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

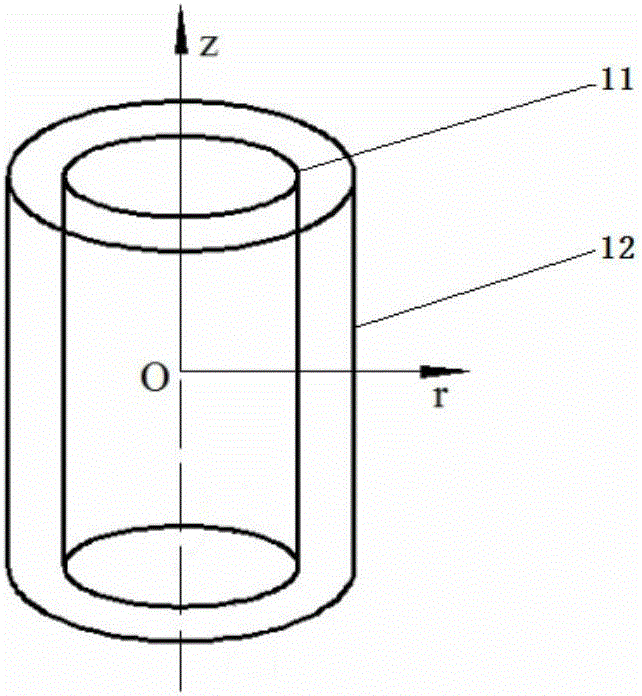

[0031] Dielectric permittivity is one of the properties of dielectric materials, and changes in the type and composition of dielectric materials will change their permittivity. In the measuring container where the magnetorheological fluid is used as the capacitor medium, during the sedimentation process of the magnetorheological fluid, the content of the components of the magnetorheological fluid changes at different liquid levels, resulting in different permittivity at different liquid levels.

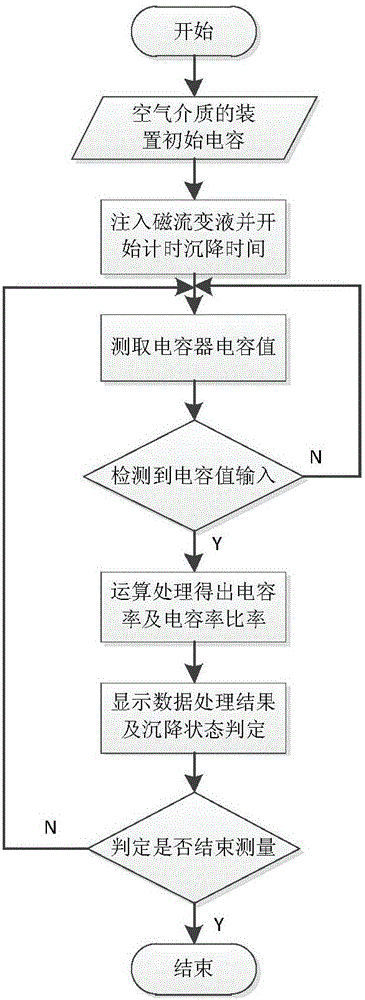

[0032] In the method of monitoring the sedimentation characteristics of magnetorheological fluid based on permittivity, the difference in permittivity of different liquid heights during the sedimentation process of magnetorheological fluid will be expressed as the change of capacitance of the magnetorheological fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com