Automatic compensation system for inner supporting axial force of foundation pit structural steel

An automatic compensation and support shaft technology, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problem that the axial force of the support beam in the steel section cannot be compensated in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

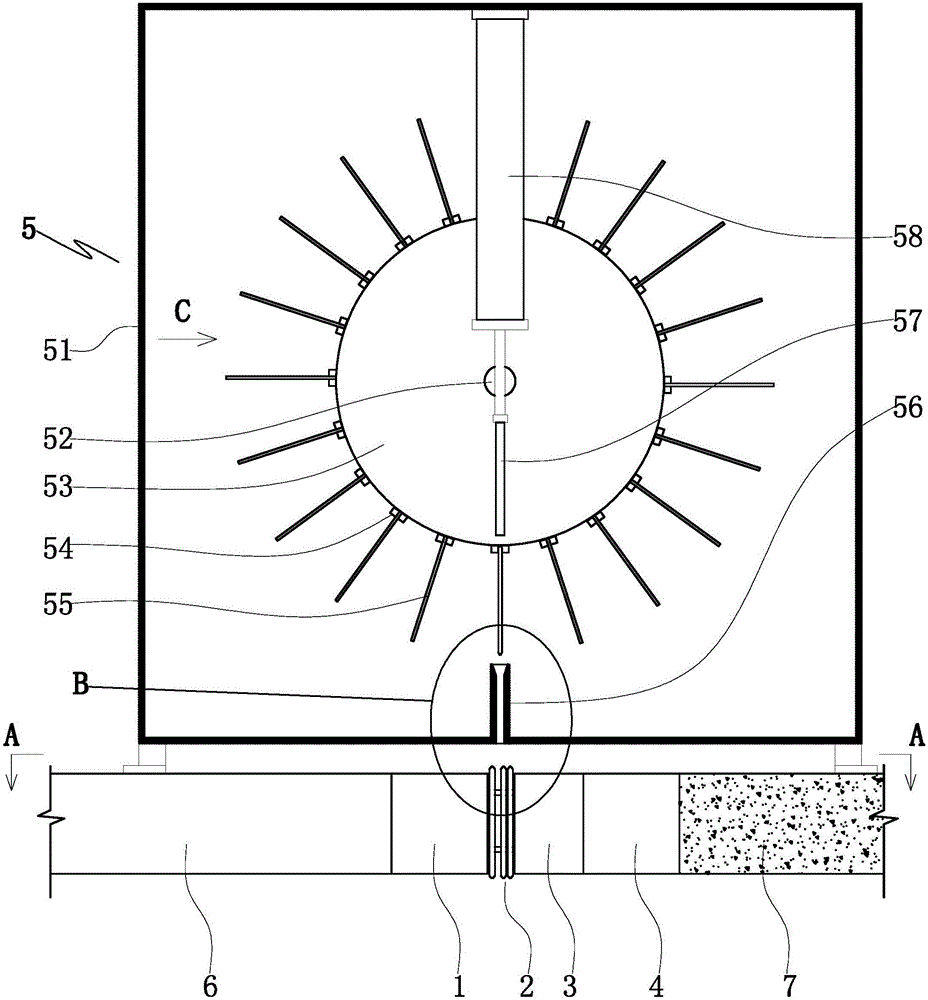

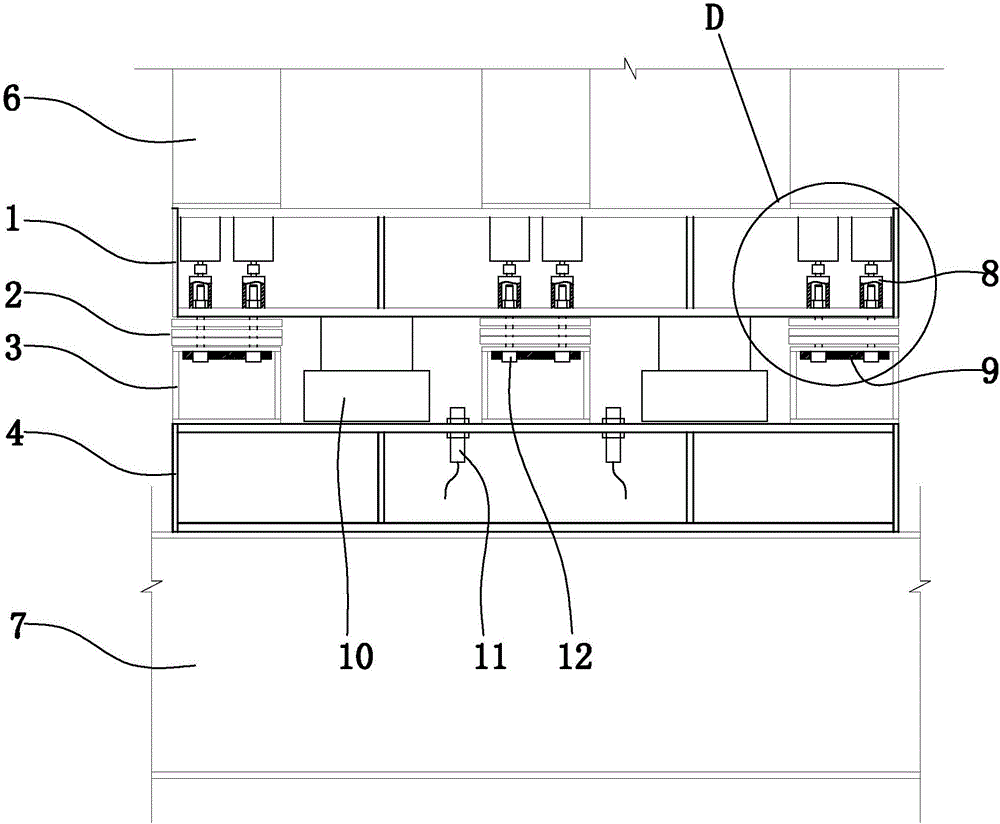

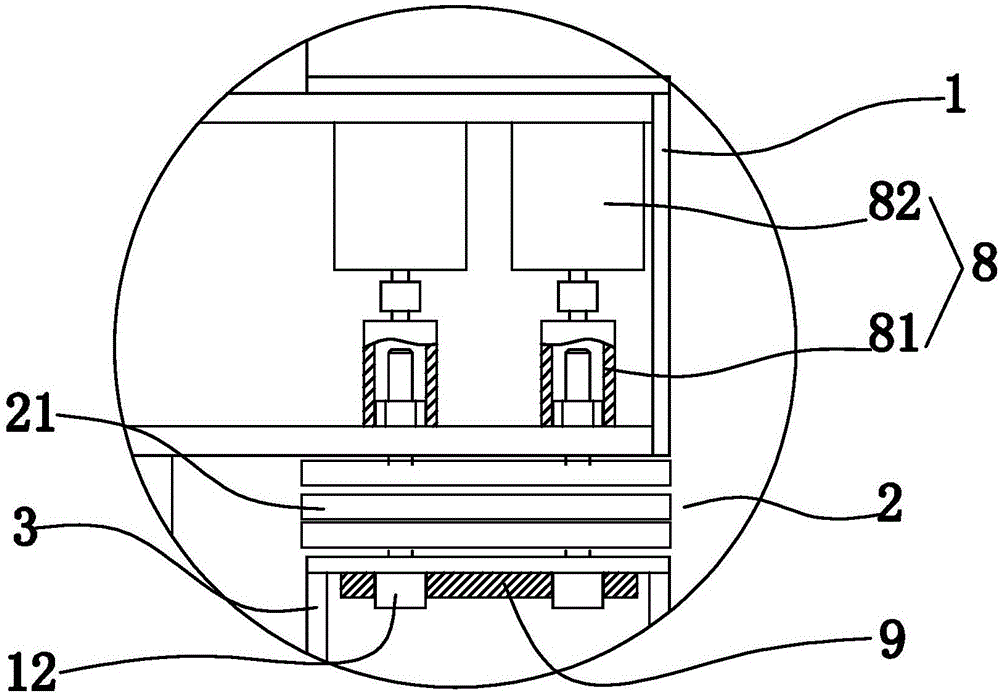

[0029] Such as figure 1 , figure 2 As shown, an automatic compensation system for the axial force of the foundation pit section steel internal support includes an axial force pressurization assembly, an axial force detection stressor (for example, an axial force gauge) and an axial force compensation device. The axial force pressing assembly includes a first supporting part 1 and a second supporting part 4 that can be stretched apart from each other, and a limit block 3 arranged between the first supporting part and the second supporting part. The first supporting part and the second supporting part are made of shaped steel, the first supporting part and the second supporting part of this embodiment are both made of H-shaped steel, and the two ends of the H-shaped steel constituting the first supporting part and the second supporting part are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com