Automatic box folding machine

A folding box machine, automatic technology, applied in container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve problems such as low work efficiency and poor quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

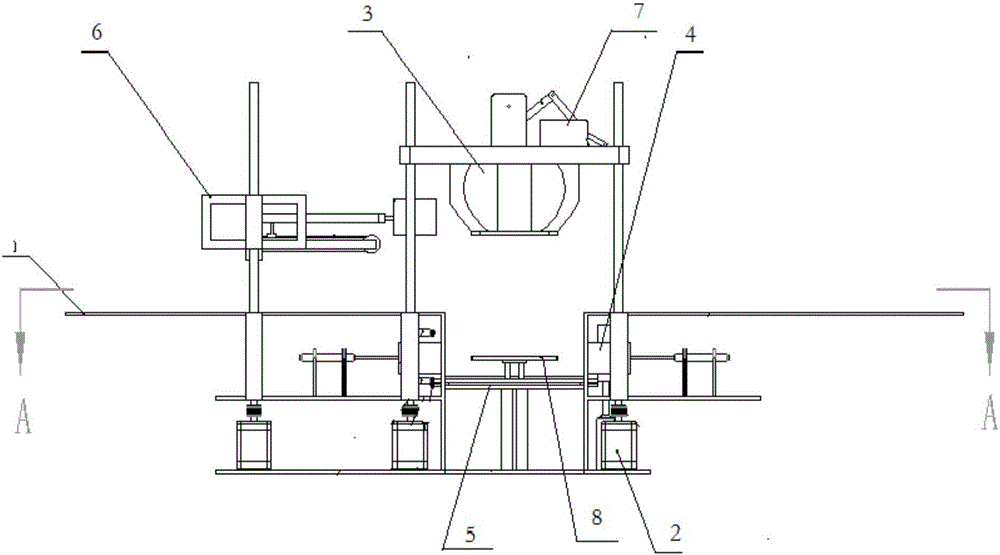

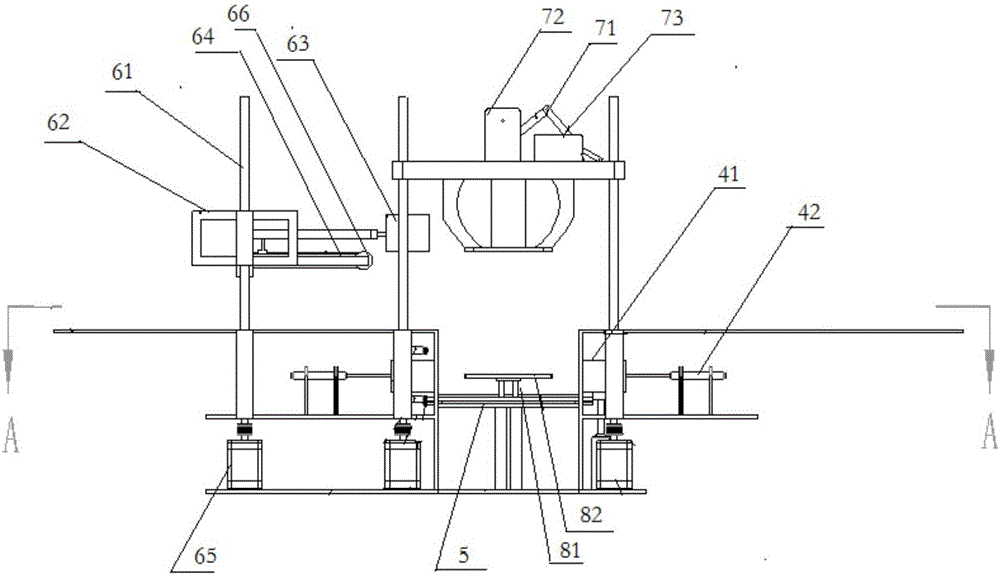

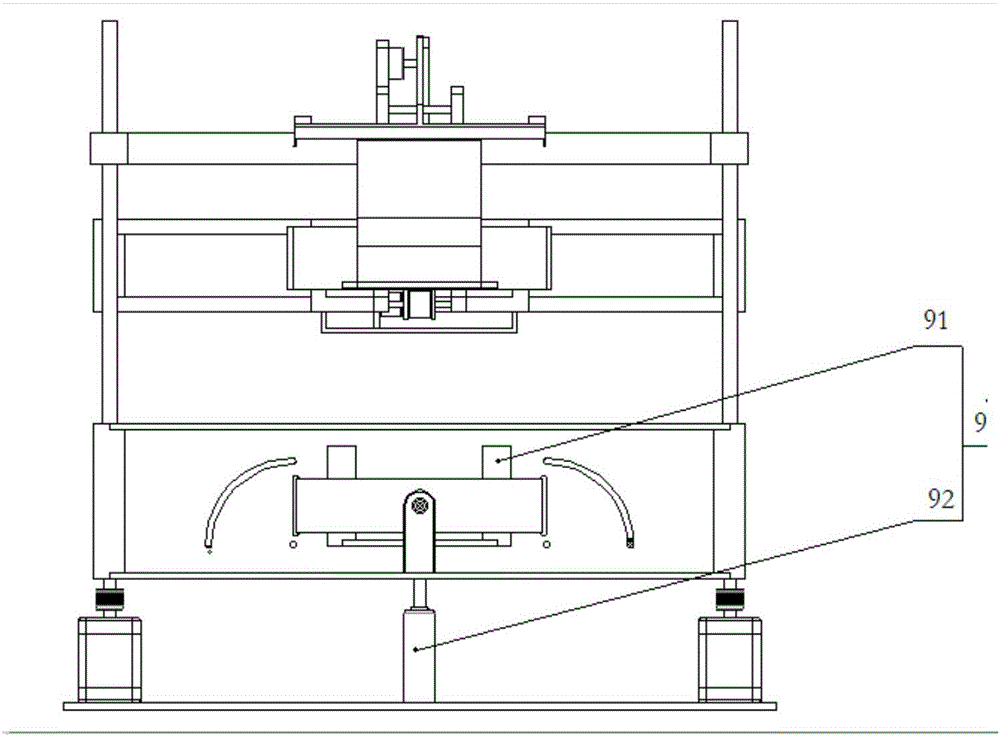

[0044] The embodiments of the present application provide an automatic box folding machine, which solves the technical problems of low work efficiency and poor quality stability in the prior art for packaging small commodities by manual folding.

[0045] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0046] An automatic box folding machine, applied to a type of cardboard, the box folding machine includes: a main body panel, including a top panel, a partition panel, a bottom panel, a side panel and a middle panel, wherein the top panel, side panels and middle panel form a folding In the concave space of the cardboard, the partition board, the middle board and the bottom board are arranged in parallel, and the partition board separates the top board and the bottom board into two layers of space; the first driving mechanism is arranged on the bottom board; The pressing m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap