Carton folding device applied to guide-rail carton packing machine

A cartoning machine and guide rail technology, applied in packaging and other directions, can solve problems such as affecting work efficiency and inability to fully automate cartoning, and achieve the effects of improving production efficiency, reliable cartoning, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments will be described in detail below in conjunction with the accompanying drawings.

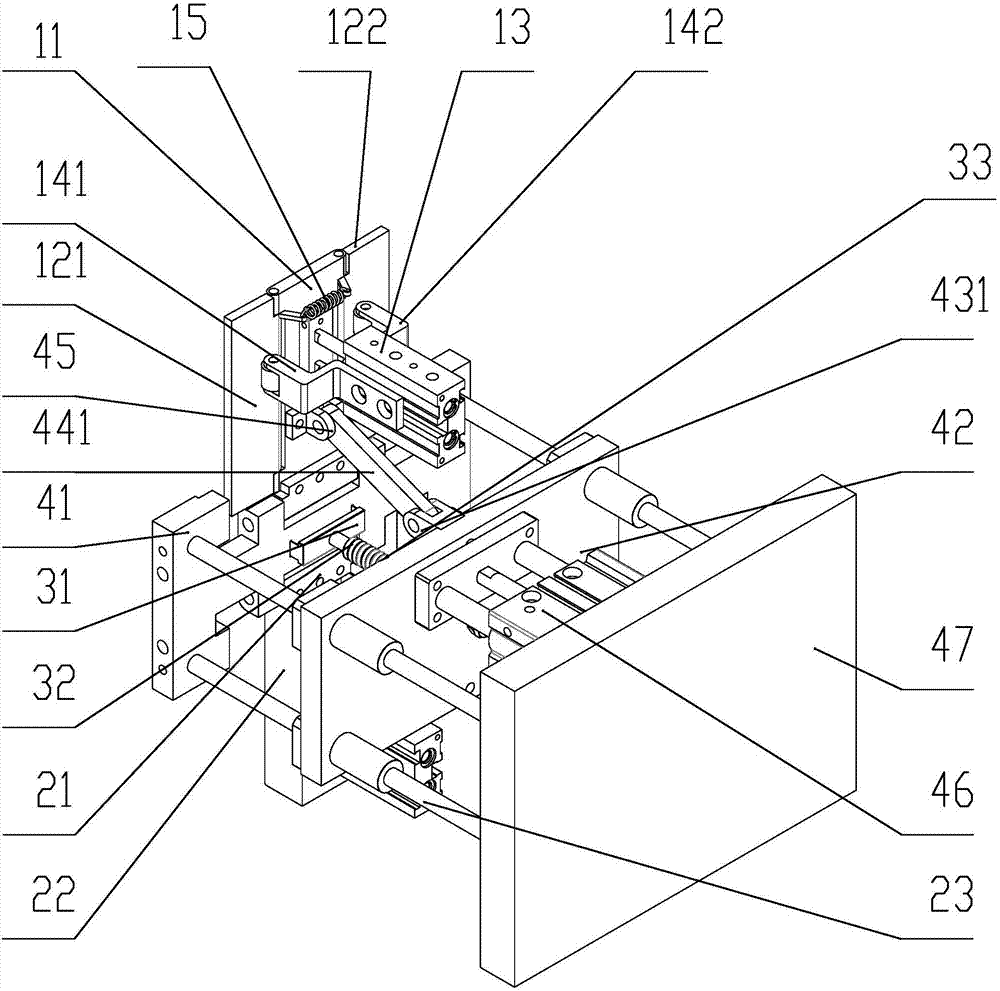

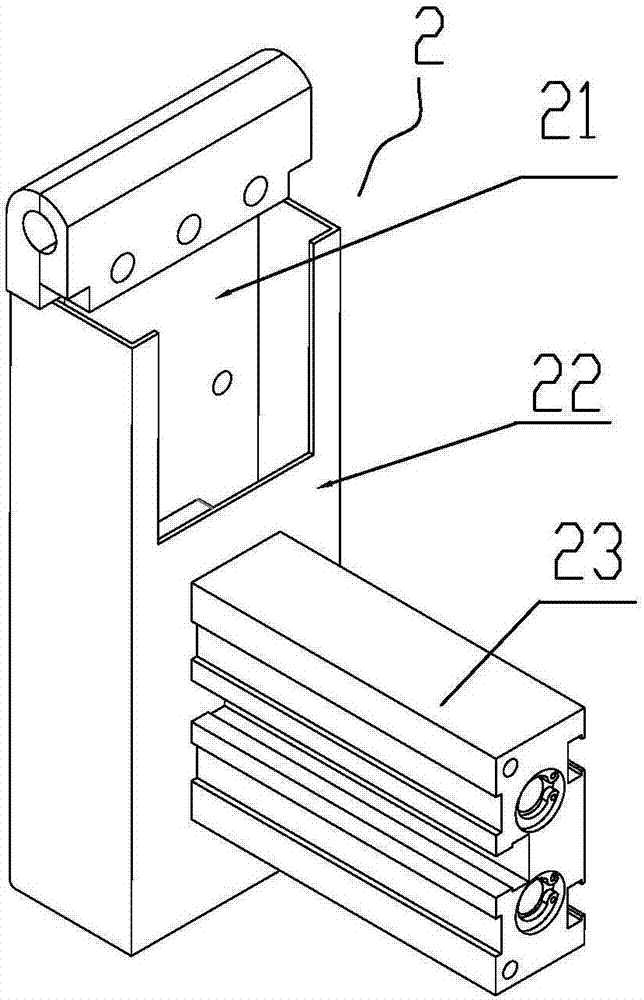

[0031] Figure 1-9 The box folding device shown in the guide rail cartoning machine includes an upper box folding mechanism 1, a lower box folding mechanism 2, a rear ear folding mechanism 3 and a push mechanism 4, an upper box folding mechanism, a lower box folding mechanism and a rear folding ear The working faces of the mechanism all face the guide rail 60 used as the folding mould. The upper folding box mechanism is above the lower folding box mechanism, and the rear folding ear mechanism is located between the upper folding box mechanism and the lower folding box mechanism.

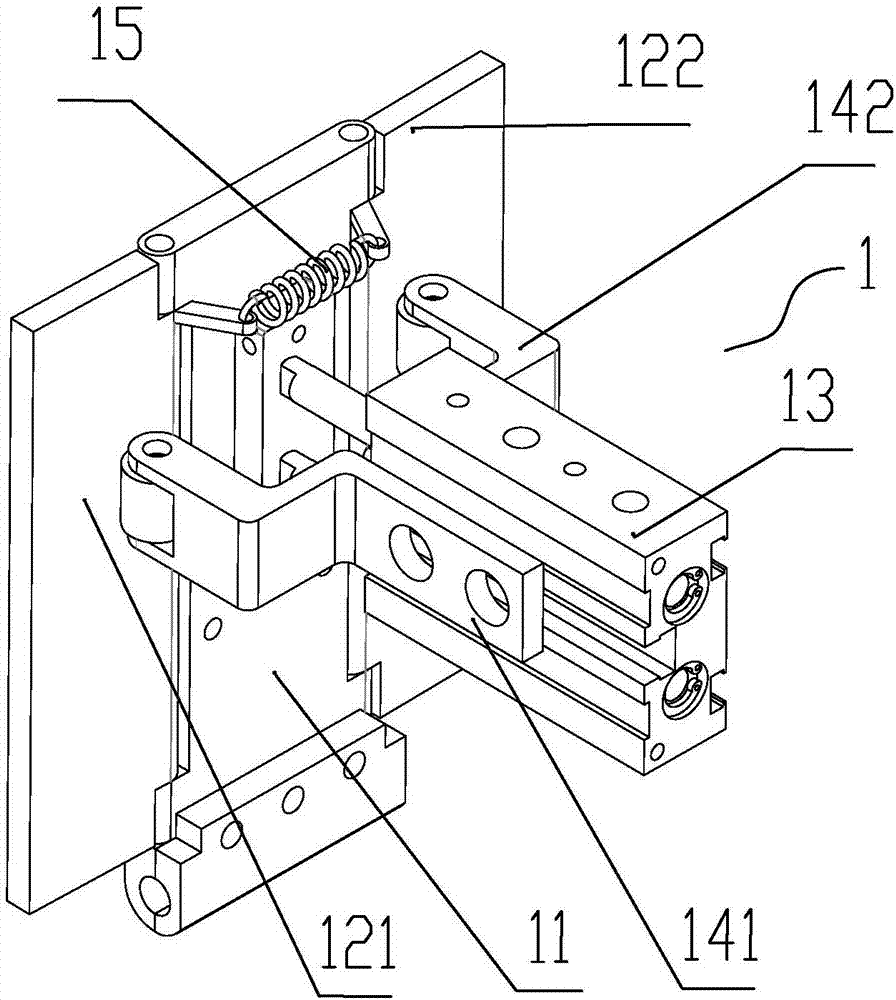

[0032] Such as figure 2 As shown, the upper folding box mechanism includes an upper flap 11, a small flap one 121, a small flap two 122, an upper cylinder 13, a pressure leg one 141, a pressure leg two 142, and an extension spring 15. The push panel 41 is arranged vertically and is fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap