Box folding mechanism

A box-folding and bending technology, applied in container manufacturing machinery, box-making operations, paper/cardboard containers, etc., can solve the problems that paper packaging boxes cannot be folded at one time, the structure of box-folding machines is complex, and there are many folding processes. To achieve the effect of compact structure, simple structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

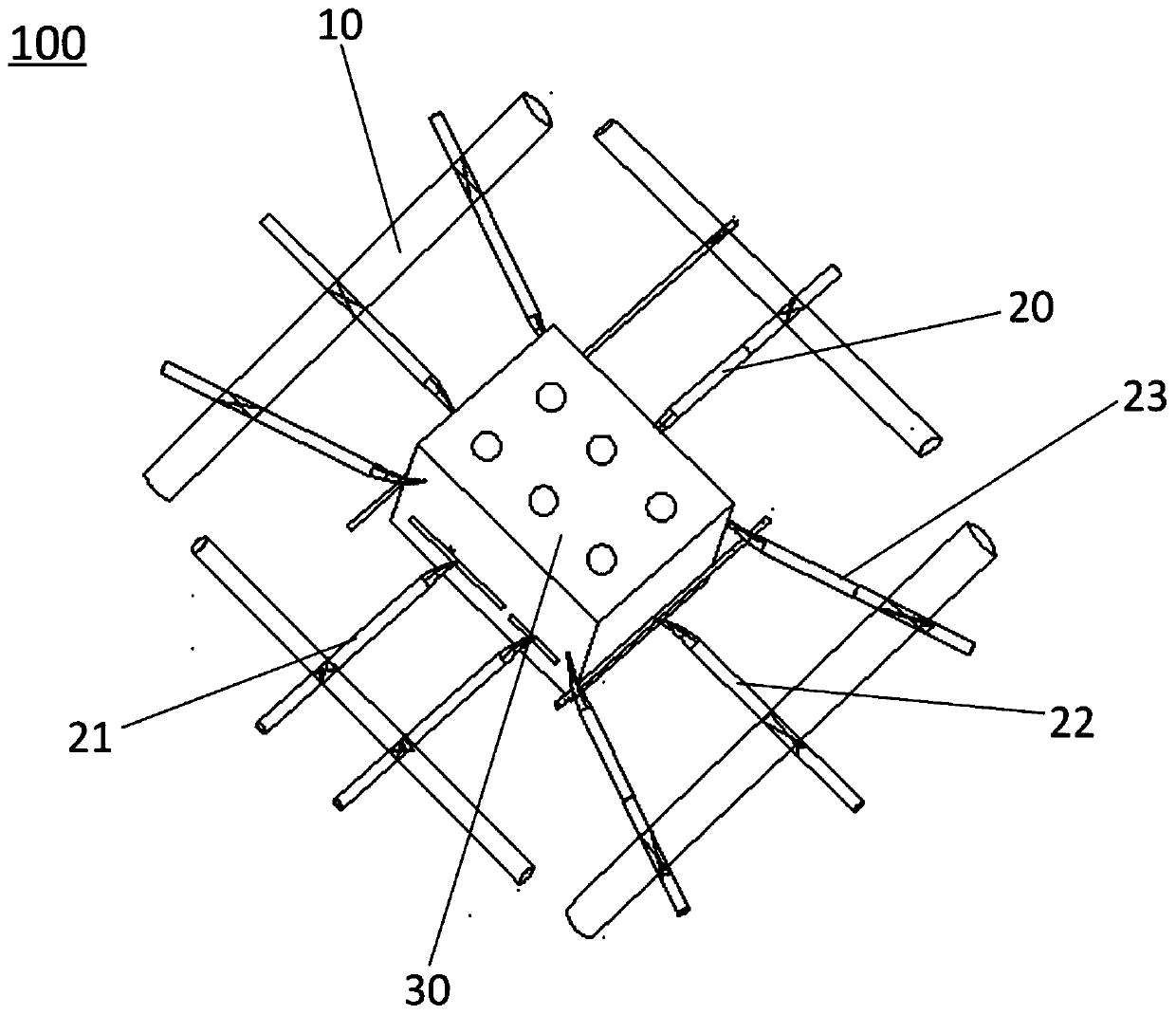

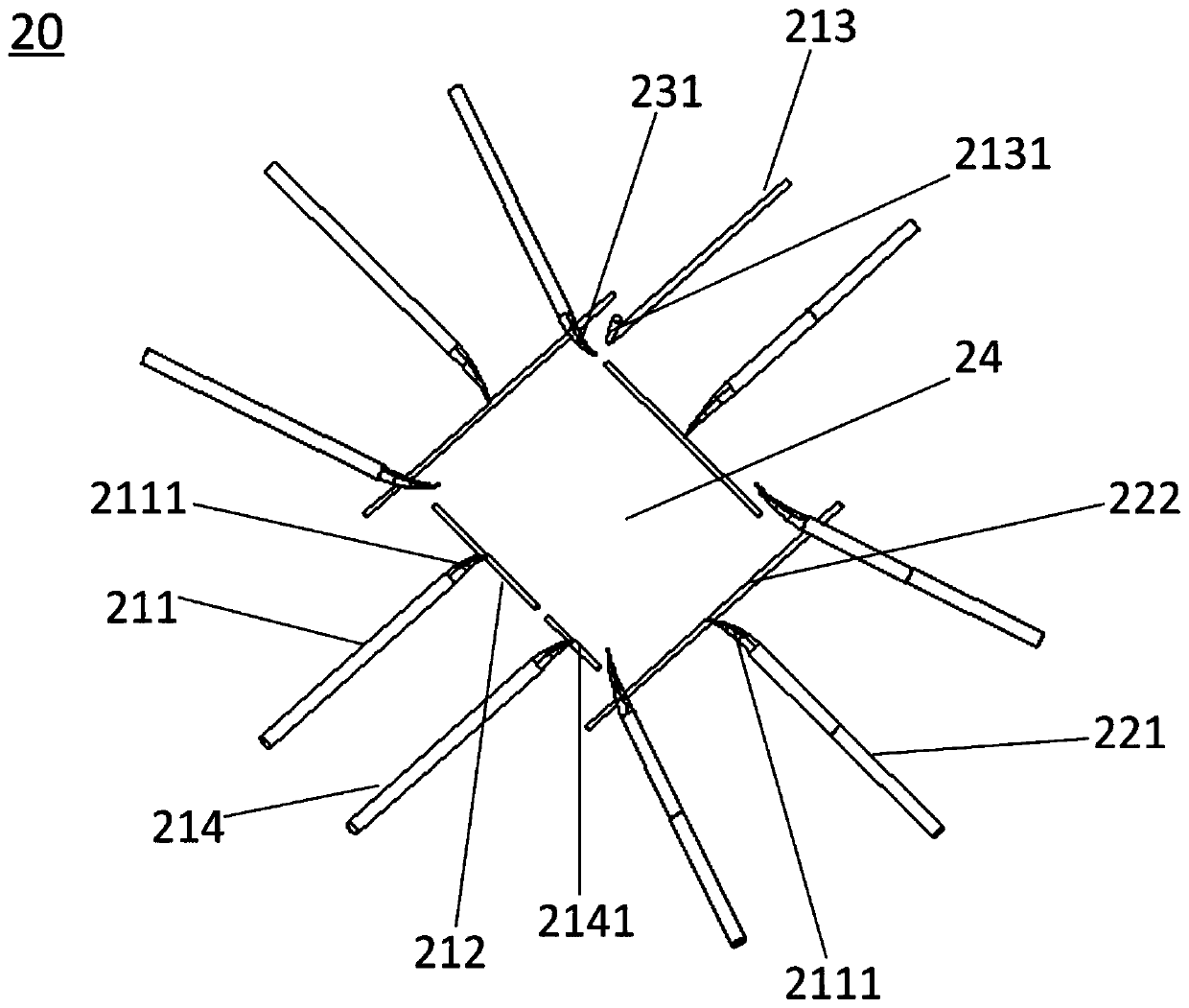

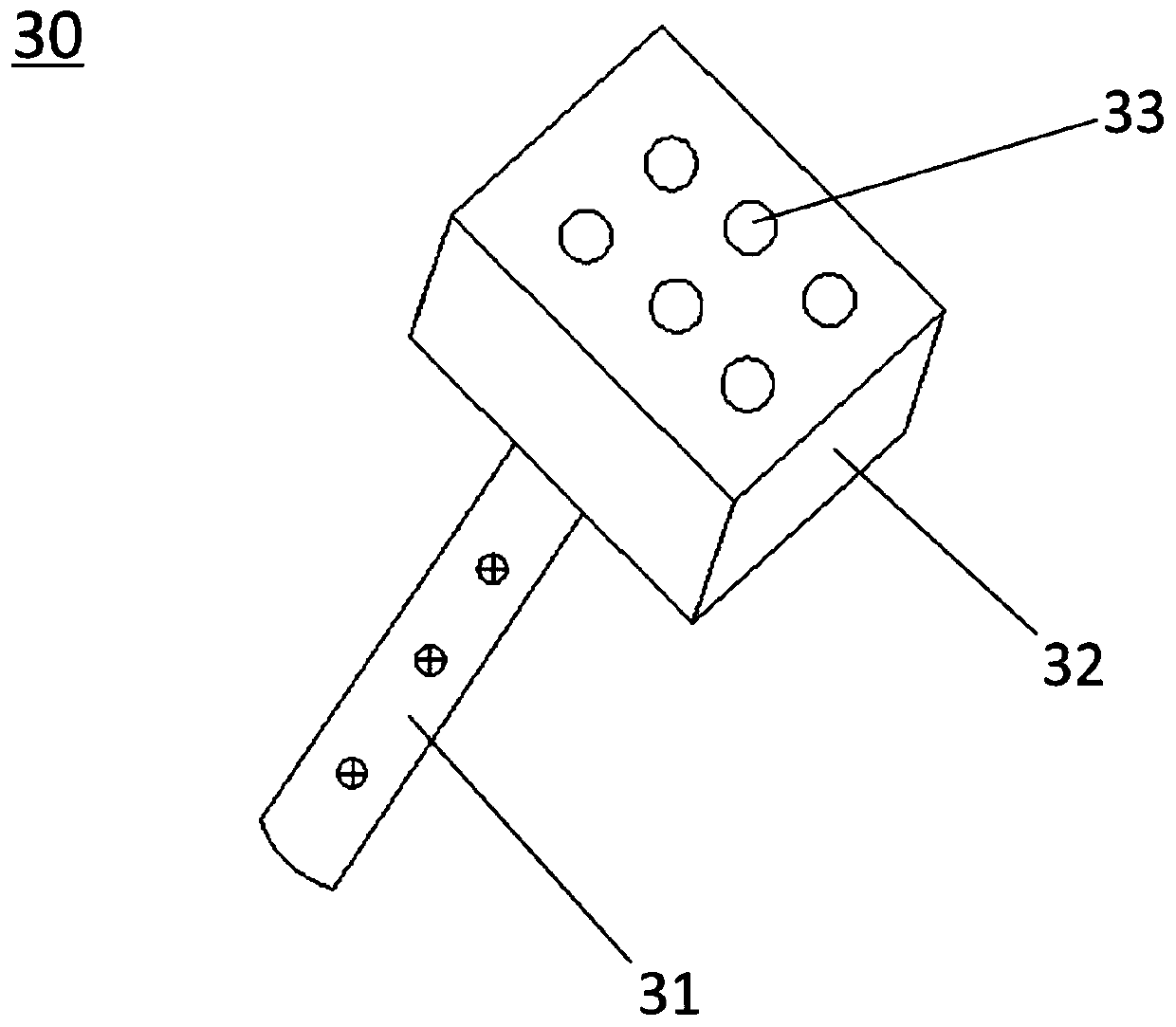

[0021] see Figure 1 to Figure 4 , the present invention is a box folding mechanism 100 for folding a blank cardboard 200 into a carton board 300 , the carton board 300 includes a box bottom 301 , side ears 302 , box sides 303 and a box top 304 . The folding box mechanism 100 includes a fixed frame 10 , a folding assembly 20 disposed on the fixed frame 10 , and an ejecting assembly 30 that cooperates with the folding assembly 20 .

[0022] see figure 1 and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap