Embedded junction box for buildings and construction method of embedded junction box

A technology for junction boxes and buildings, which is applied in the directions of buildings, building structures, cable installation devices, etc., can solve the problems of inconvenient installation and poor sealing effect of ordinary junction boxes, and achieve convenient installation, beautiful decoration effect, safety, The effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

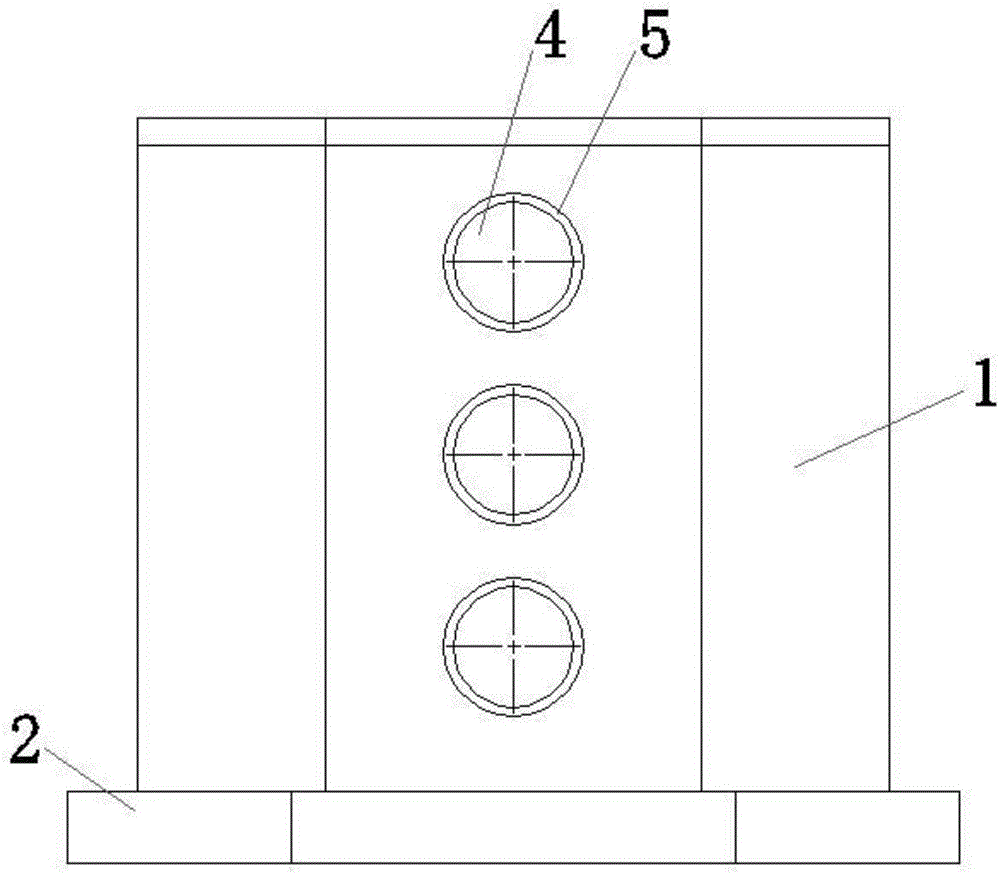

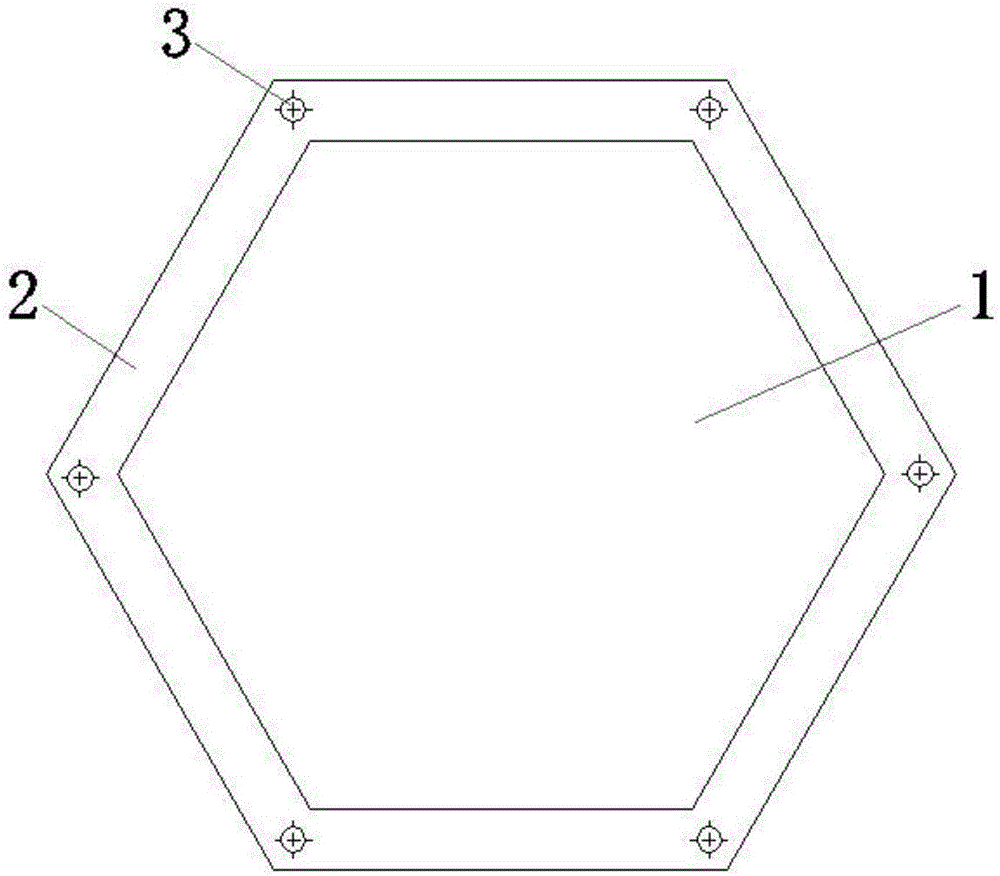

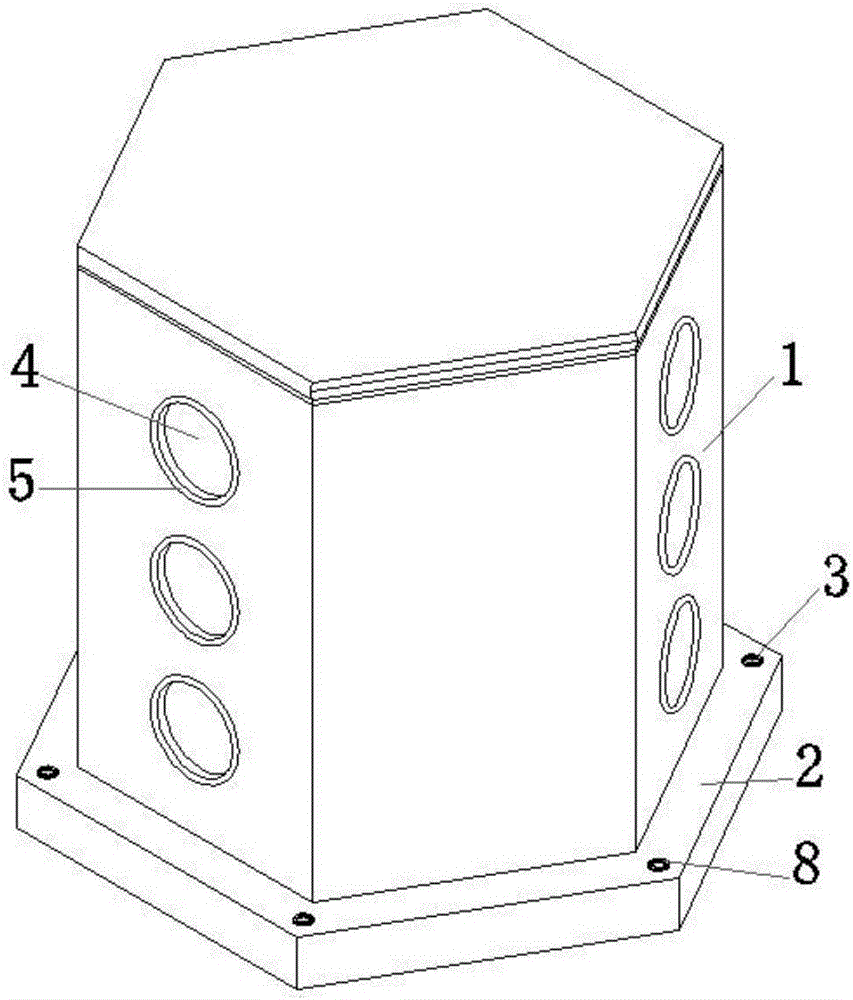

[0032] like Figure 1 to Figure 5 As shown, a pre-embedded junction box for construction is a hollow structure, which is characterized in that it includes a body 1, a base 2 and a head 7, the body 1 is a hollow structure with a regular polygonal horizontal section, and the top of the body 1 Sealing, one of the adjacent sides of the body 1 is provided with a threading hole 4, and an inwardly recessed gasket 5 is fixed on the threading hole 4; the base 2 is located directly below the body 1 and is fixedly connected to the body 1 As a whole, the base 2 is a hollow structure with a regular polygonal horizontal section, the side length of the regular polygon is longer than the side length of the regular polygon of the body 1, the base 2 is provided with a screw hole 3, and the screw hole 3 is located on the front At the corners of the polygon, the bottom surface of the base 2 is provided with a concave step 6 , and the sealing head 7 is bonded and adapted to the concave step 6 .

...

Embodiment 2

[0041] like Figure 1 to Figure 5 As shown, a construction method of a pre-embedded junction box for construction, the pre-embedded junction box has been filled with fillers such as sawdust before being sent to the construction site, and then the sealing head 7 is bonded to the bottom surface of the base 2, and the sealing gasket 5 All are inserted into the threading holes 4 and bonded tightly; the pre-embedded junction box has been inserted into the screw holes 3 before sending to the construction site. During the construction process, the cement nails are nailed to the corresponding positions of the formwork, and during the later decoration process, the operator only needs to open the head 7 to carry out line maintenance or installation work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com