Multifunctional steam dump control system and control method

An emission control system and steam system technology, applied in the direction of steam engine devices, steam engines, machines/engines, etc., can solve the problem of not considering the appropriateness of the closing process of the cut-off process at the end of the discharge, affecting the safety of ships operating in steam power devices, and unable to discharge in an appropriate amount Control and other issues, to achieve the effect of avoiding multiple frequent discharges, rapid action, and complete discharge functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

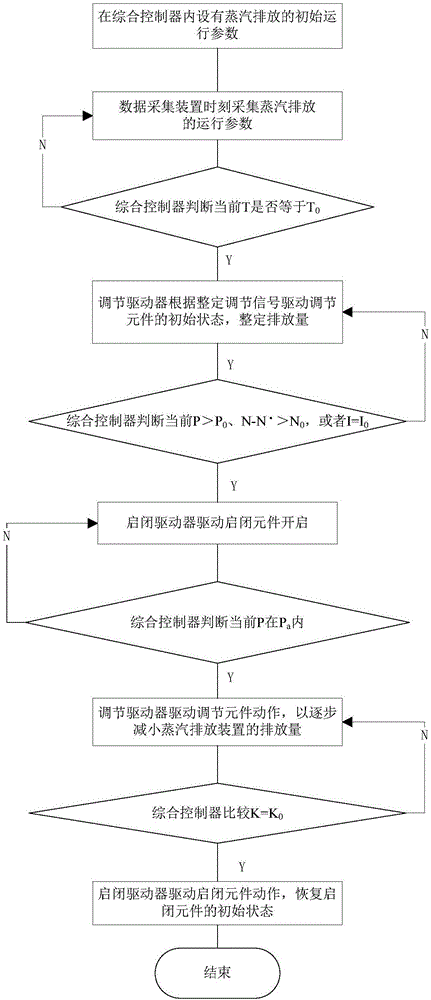

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

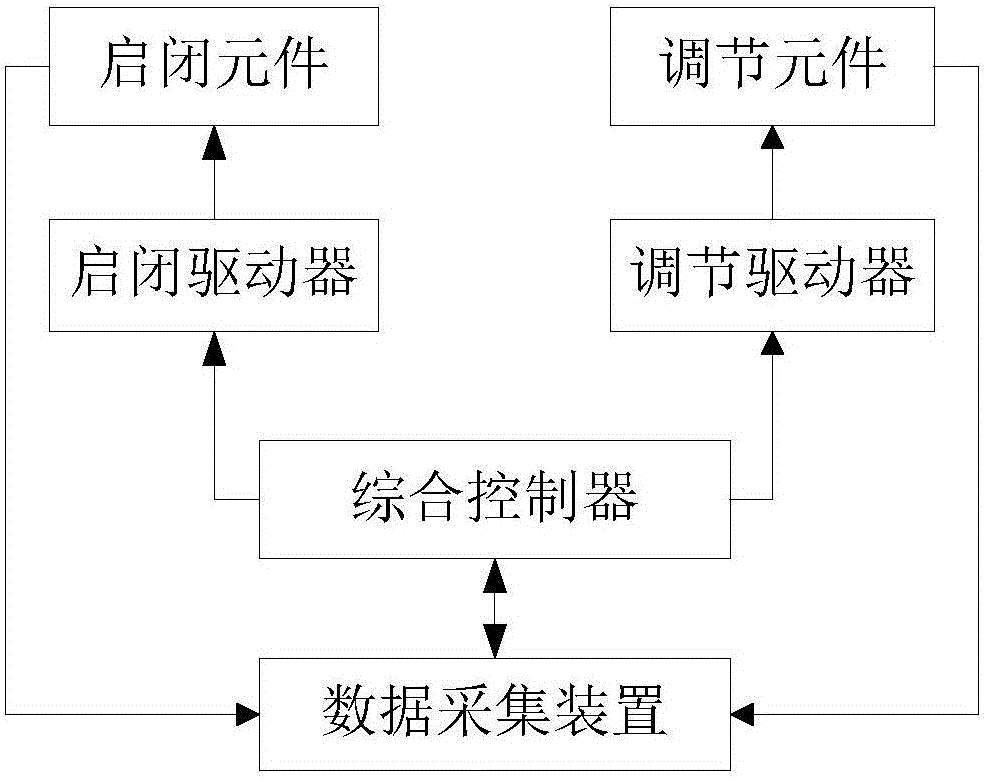

[0035] see figure 1 As shown, the embodiment of the present invention provides a multifunctional steam emission control system, including:

[0036] Data acquisition device, the data acquisition device is used to collect operating parameters of steam discharge during the steam discharge process; the operating parameters include the switch state T of the opening and closing element, the flow rate of the steam turbine regulating valve, the pressure P of the main pipe of the steam system, and the stable value range of the main pipe pressure of the steam system P a , device operating power N, system load power N · , the signal value I of steam turbine speed closing, and the opening degree K of the regulating element.

[0037] An integrated controller connected to the data acquisition device, the integrated controller is equipped with initial ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com