Turnover mechanism of electrode plate

A technology of flipping mechanism and electrode sheet, which is applied in the direction of electrodes and electrode manufacturing of primary batteries, can solve the problems of potential safety hazards and low efficiency, and achieve the effect of saving labor costs, improving work efficiency, and realizing automatic integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

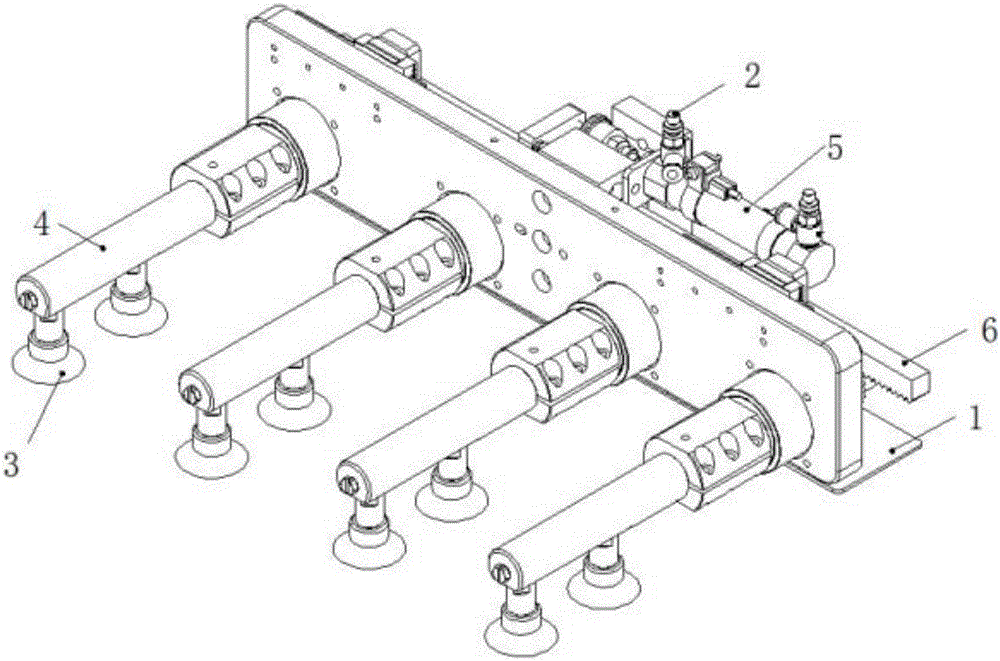

[0012] See figure 1 As shown, a flipping mechanism for an electrode piece includes a support base 1, a row of battery sucker rotating rods 4 on one side of the base 1, and one end of the battery sucker rotating rods 4 passes through the supporting base 1 and the flipping push cylinder 5 connect. Two groups of vacuum suction cups 3 are arranged at the bottom of the battery suction cup rotating rod 4 . The turning push cylinder 5 is rotationally connected with the end of each battery sucker rotating rod 4 through the turning rack 6 . The overturning push cylinder 5 is provided with a speed regulating valve 2 for controlling the overturning speed.

[0013] The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments of the present invention and are not intended to limit the present invention. Any modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com