A screen-off developing protective film, a preparing method thereof and a screen-off developing method

A developing method and protective film technology, which can be applied to chemical instruments and methods, synthetic resin layered products, layered products, etc., and can solve problems such as lack of visual effects and single functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

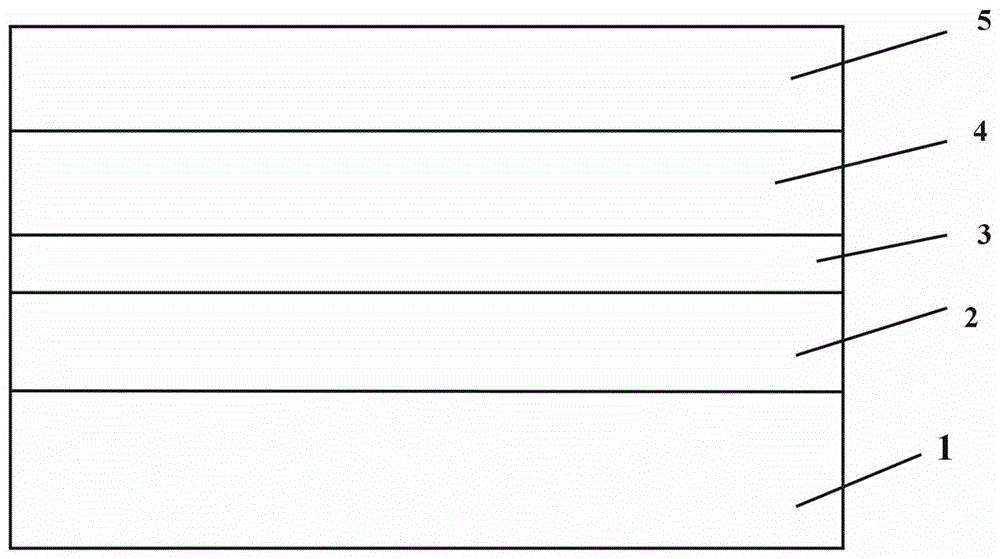

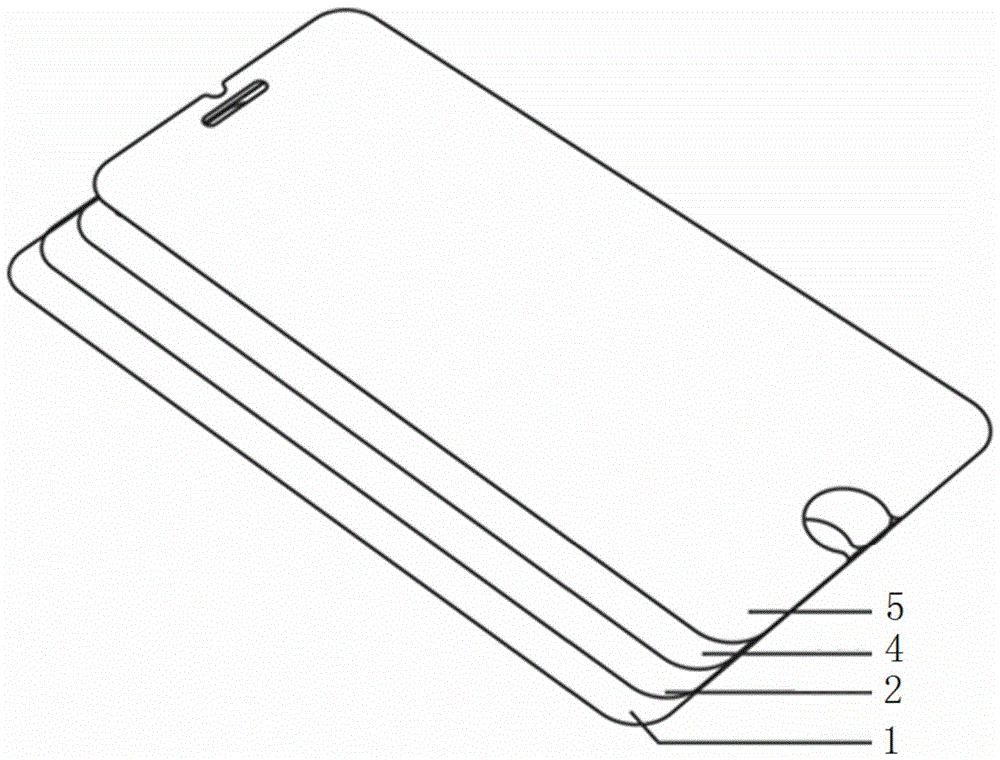

[0032] Example 1: as Figures 1~3 , an interest screen developing protective film, comprising a release film, a silica gel layer, an OCA adhesive layer and a protective film stacked in sequence; it is characterized in that a layer of developing ink is printed on the silica gel layer; the developing ink layer is located between the silica gel layer and the OCA layer. Between the adhesive layers, there is ink in some areas of the developing ink layer, and no ink exists in the rest. The area where the ink exists is the developing pattern area (used to form the developing pattern in the screen-off state).

[0033] The developed ink layer is white ink with a thickness of less than 1 u.

[0034] The developing ink layer is printed with transparent white ink below 3% (including 3%). 3% refers to 3% of white ink dots, and the white ink model is: T639B. 3% of white ink dots means that the area of white ink dots accounts for 3% of the total area.

[0035] The thickness of the devel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com