Adjustable conveying device

A transmission device and adjustable technology, applied in the directions of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of easy scratches, affect appearance, affect production efficiency, etc., to improve work efficiency, easy to use, device simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

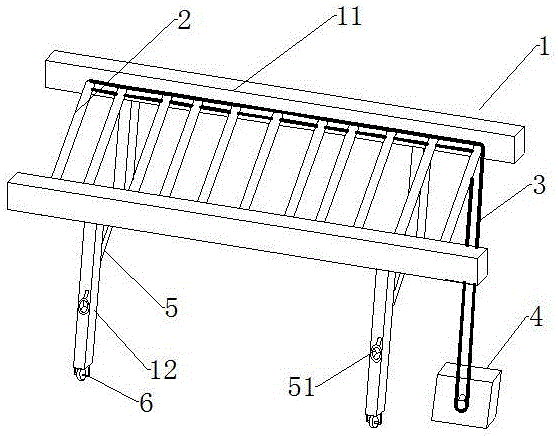

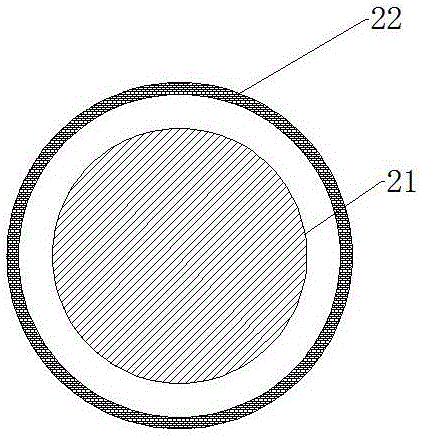

[0021] Such as figure 1 with figure 2 An adjustable transmission device shown is used for the transmission of stainless steel composite plates, including a bracket 1, a rolling rod 2, a transmission chain 3 and a driving device 4, and the rolling rod 2 is horizontally installed on the longitudinal link 11 of the bracket 1 Each rolling rod 2 is connected by a transmission chain 3, and the transmission chain 3 is transmitted by a driving device 4, and a screw device 5 for adjusting the lateral width of the support 1 is connected between the lower columns 12 of the support 1, The bottom end of the lower column 12 is provided with a roller device 6, and the inside of the rolling rod 2 is provided with a telescopic rod 21 that is automatically adjusted as the lateral width of the support 1 changes, and the two ends of the telescopic rod 21 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com