Continuous Mining Method of Gently Inclined Vein Based on Combined Chessboard Bottom Structure

A technology of bottom structure and mining method, applied in surface mining, underground mining, special mining, etc., can solve the problems of hidden safety hazards, difficult roof management, and high stope ceiling, achieve high safety operating conditions, and shorten stope mining time. , the effect of large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

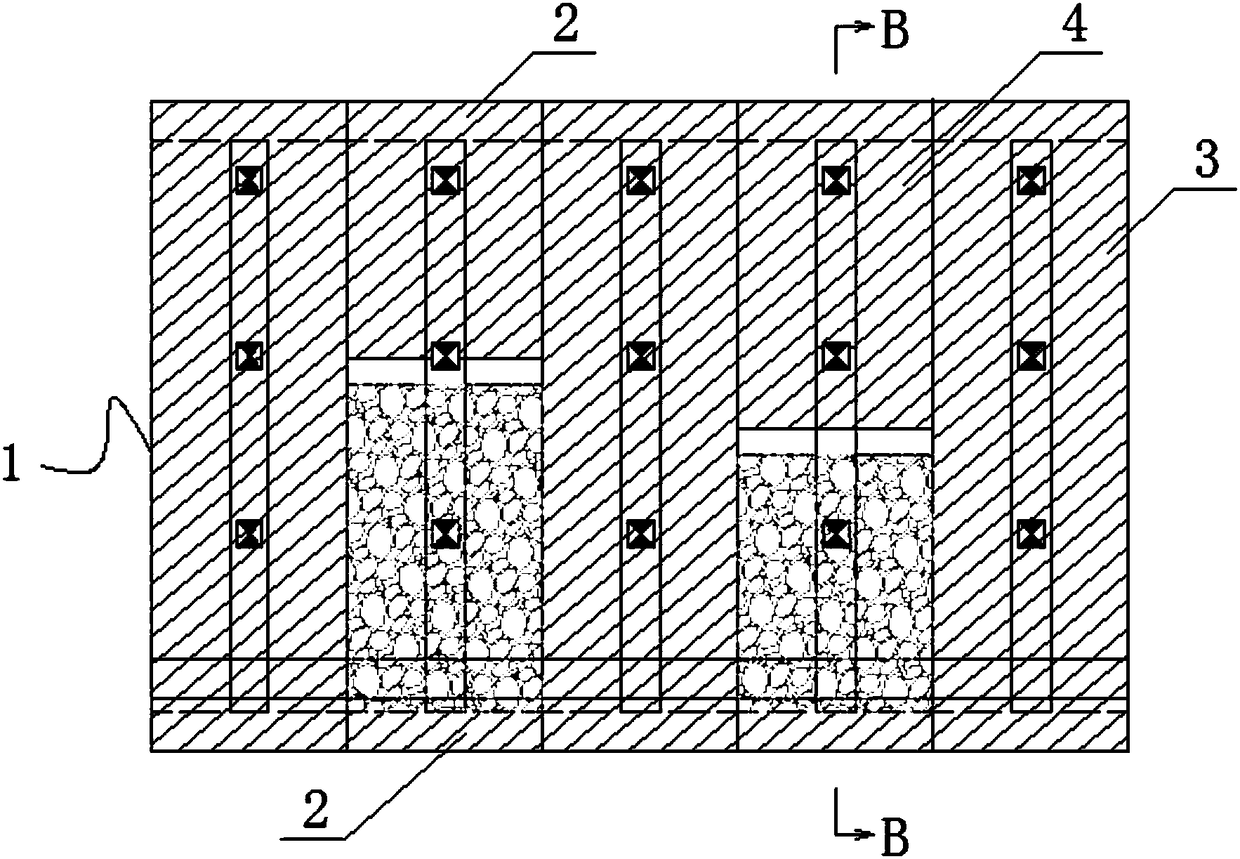

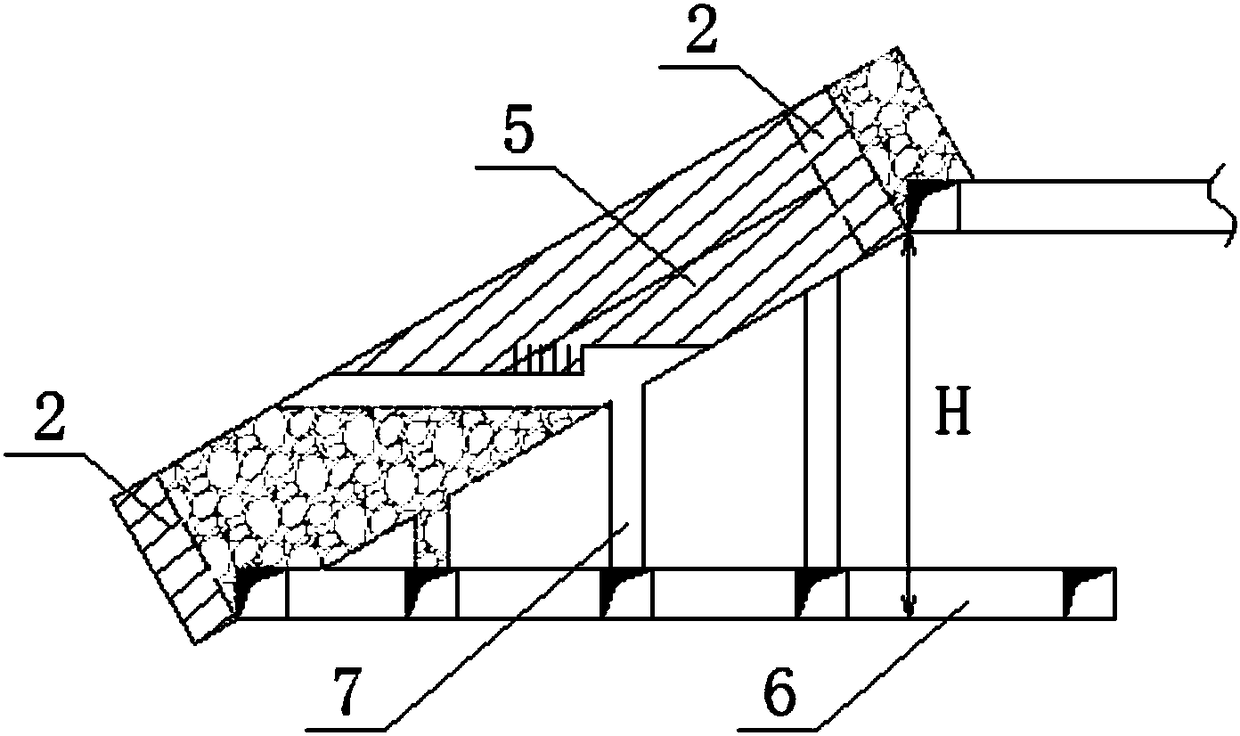

[0031] like Figure 1-4 As shown in one of the present invention, a kind of gently inclined ore vein continuous mining method based on the combined checkerboard bottom structure of the present invention, the mining method comprises the following steps:

[0032] 1) The ore body 1 with a dip angle of 20-35° is divided into the middle section along its dip, and the upper and lower ends of the middle section are respectively reserved with inclined roof pillars 2, and the ore body 1 is divided into alternately arranged mine houses 4 and ore pillars 3 along the strike , implement the mining sequence of first mining room 4 and then mining pillar 3, ore pillar 3 and mine room 4 form a panel every 5-8, and form a panel, wherein the height H of the middle section of ore body 1 is 30m, and the inclined roof The thickness of the pillar 2 is 5-10 meters, the width of the mine house 4 is 8-10m, and the width of the mine pillar 3 is 10-15m;

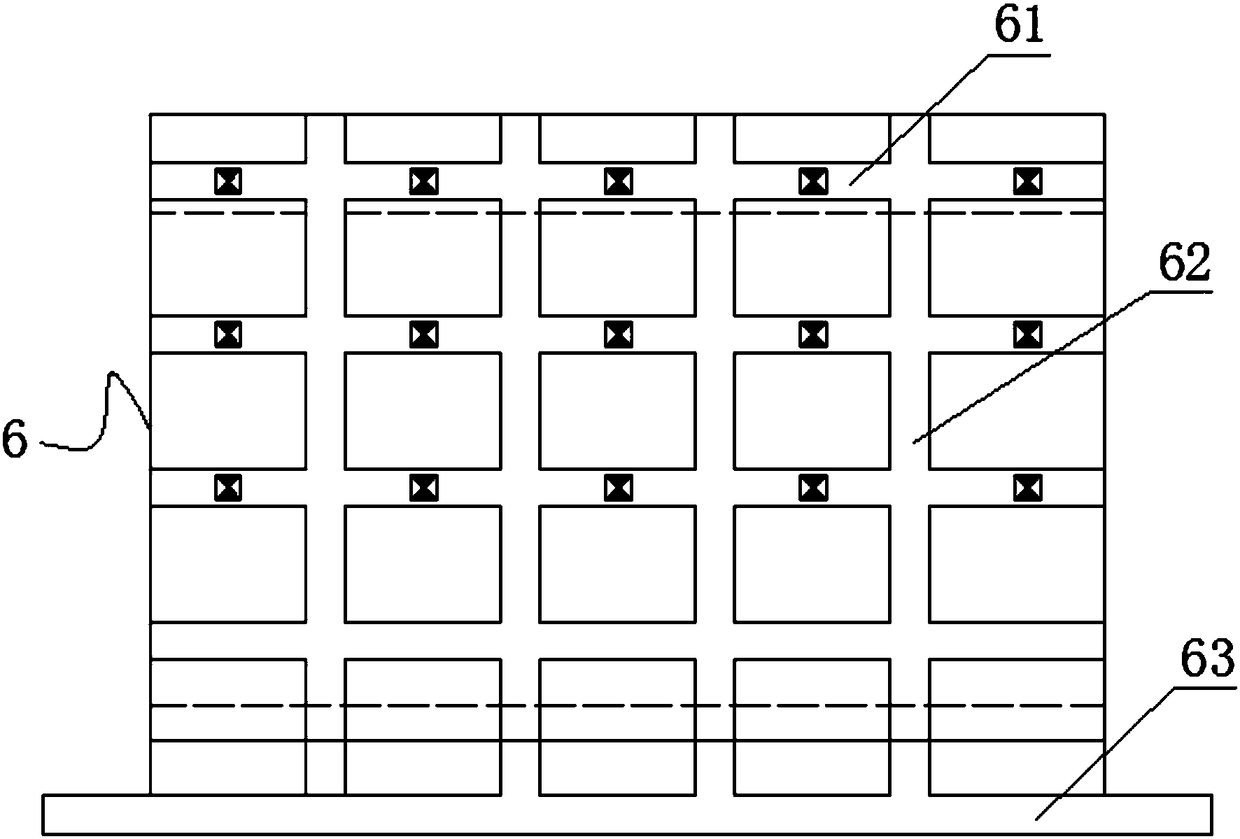

[0033] 2) Establish a checkerboard-type ore-disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com