Double drive planetary gear reducer and hydraulic clutch device

A technology of planetary reducer and hydraulic clutch, which is applied in the directions of fluid-driven clutches, non-mechanical-driven clutches, clutches, etc., can solve the problems of hydraulic clutch devices that are not compact in structure, cannot realize double-drive linkage, and cannot be combined at high speed, so as to achieve easy Automatic control, easy oil circuit setting and control, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

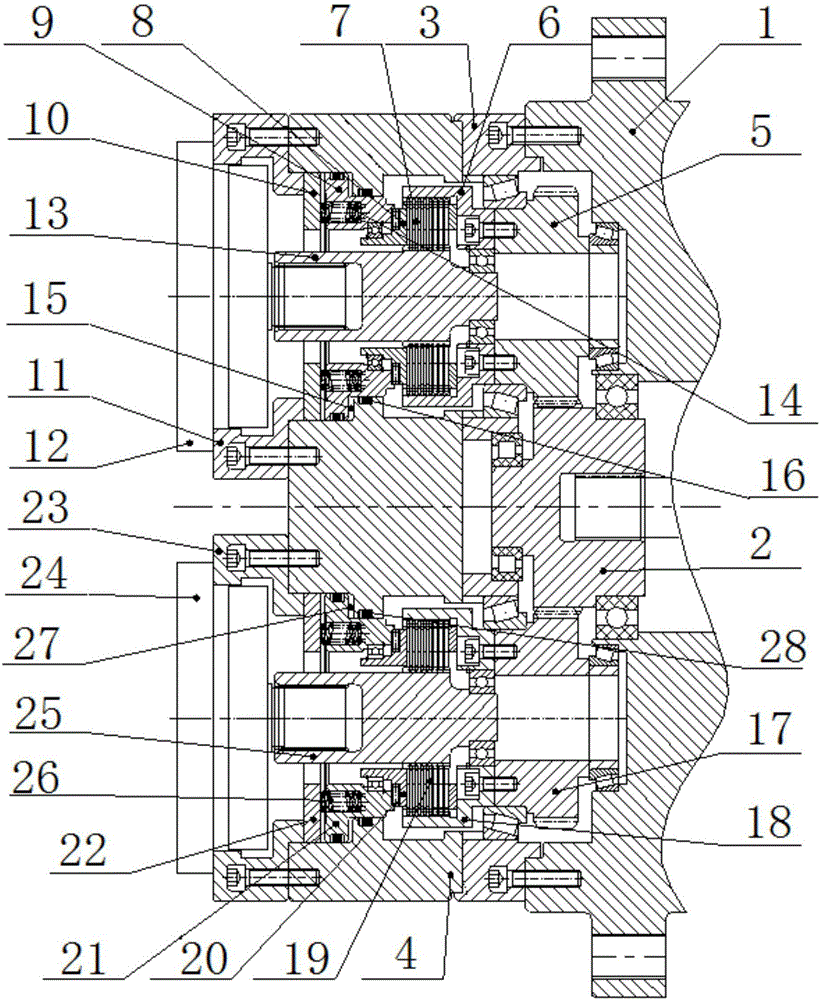

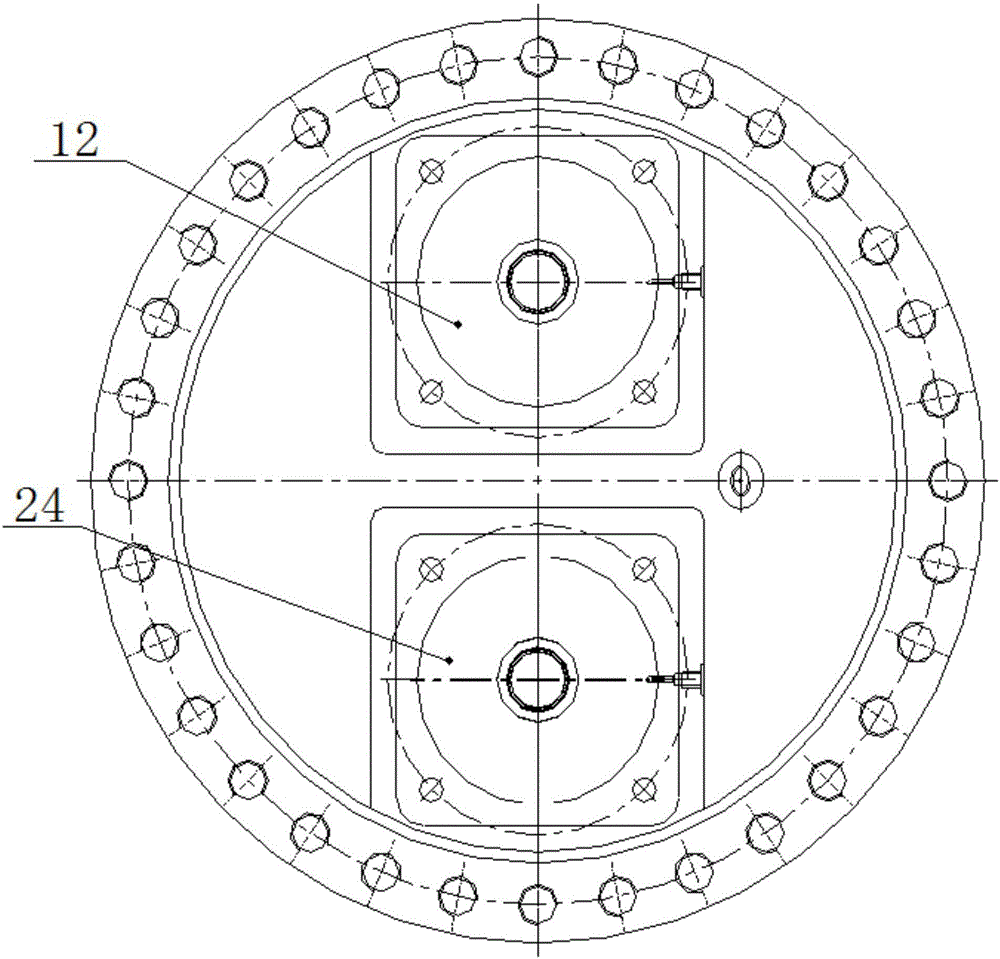

[0032] like figure 1 and figure 2 As shown, a hydraulic clutch device for a double-drive planetary reducer, including a planetary reducer base 1 and intermediate gears 2 arranged in sequence along the axis of the planetary reducer base 1, connecting a flange 3 and a clutch base 4, and also including a On both sides of the axis of the planetary reducer base 1, clutch I and clutch II with axes parallel to the axis of the planetary reducer base 1, the intermediate gear 2 is connected to the planetary reducer base 1 through a ball bearing, The connecting flange 3 is connected with the connecting flange 3 through a roller bearing, the connecting flange 3 is connected with the planetary reducer base 1 through bolts, and the clutch seat 4 is connected with the connecting flange 3 through bolts;

[0033] The clutch I includes output gear I5, output housing I6, friction plate group I7, pressure plate I8, piston I9, baffle plate I10, input end cover I11, hydraulic motor I12 and The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com