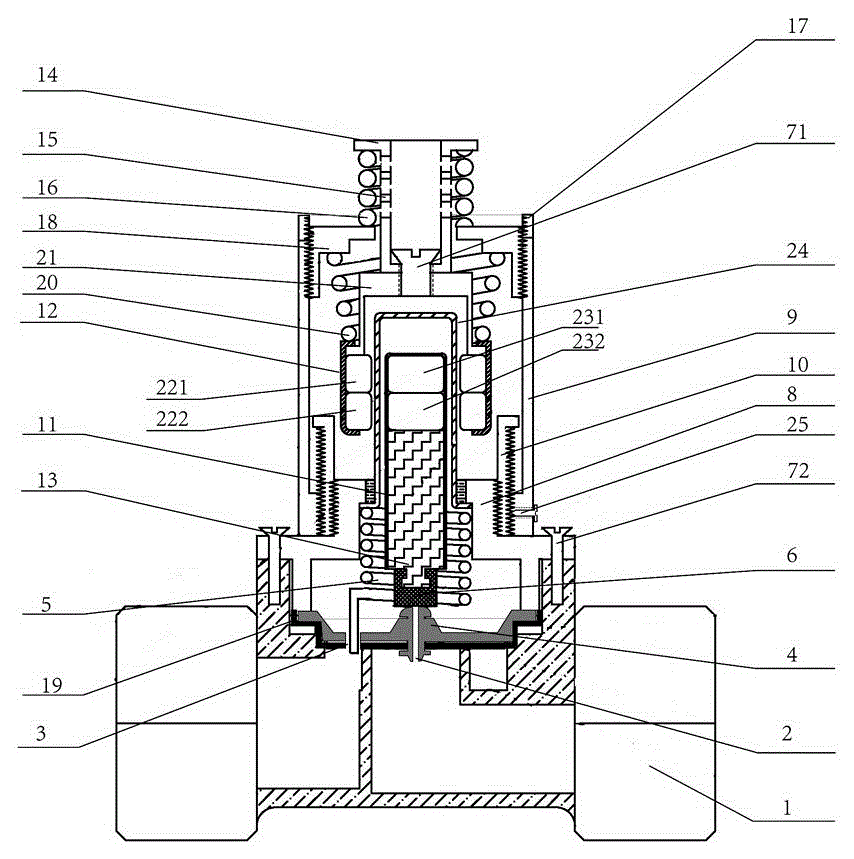

Temperature-controlled spraying fire valve capable of compensating memory alloy spring deformation error

A technology of memory alloy springs and memory alloys, which is applied to valve details, valve devices, valve operation/release devices, etc., and can solve problems such as valves not opening in time, part processing errors, and memory alloy springs being prone to errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Setting: when the ambient temperature reaches the transformation temperature of the memory alloy spring, it is 35°C.

[0014] After the sprinkler fire valve of the present invention is assembled at normal temperature, the handle (9) is rotated to drive the bias spring adjustment cap (18) to move down in the same direction, giving the bias spring adjustment cap ( 18) Apply pressure to move the magnetic ring sleeve (12) downward, so that the magnetic core assembly drives the pressure relief hole plugging pad (6) to block the pressure relief hole (2) and diaphragm downward Bracket (19), until the valve does not leak under normal conditions, at this time, rotate the handle positioning cap (17) to move down, lock the handle (9) and do not move, at this time, the switch controls the barrel (21) move down synchronously with the magnetic ring sleeve (12), so that the temperature control spring (16) is in a compressed state, and at the same time, the anti-blocking spring (5) als...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap