Large-scale vibration engineering control device optimization arrangement method

A technology of engineering control and layout method, which is applied in the direction of design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of high economic cost and unfavorable durability of steel spring vibration isolators, so as to reduce economic costs and protect Vibration isolation objects, effects of strong variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, detailed description will be given below in conjunction with the accompanying drawings.

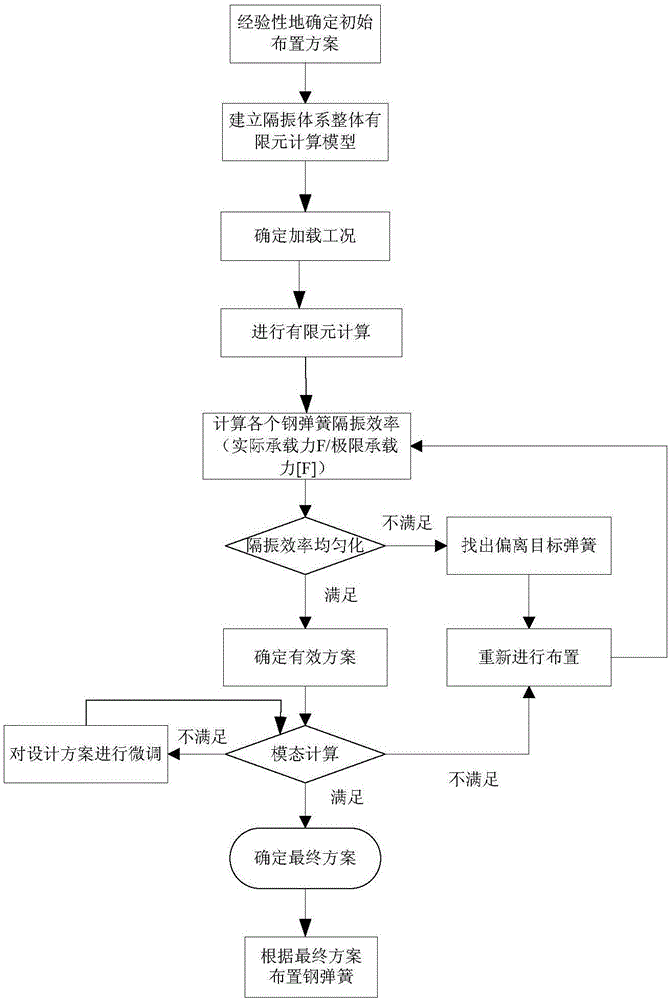

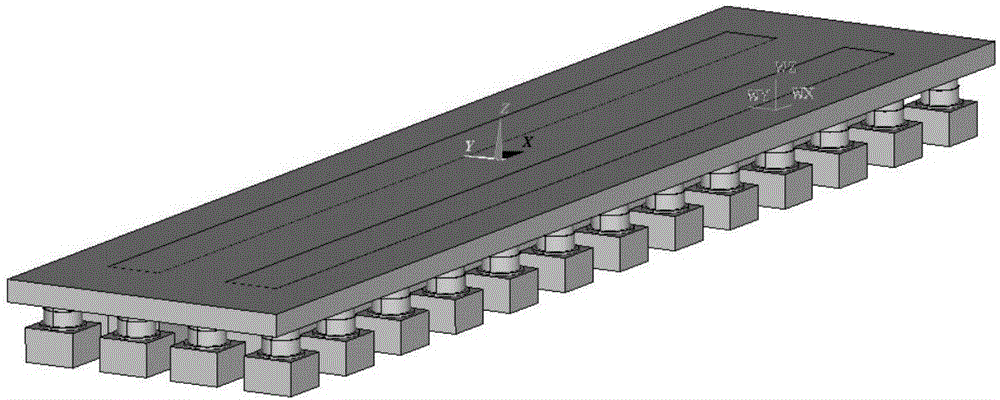

[0022] The present invention establishes the finite element calculation model of the integral steel spring vibration isolation system (including the pedestal and the steel spring), and establishes a loading parameterized command flow, and evaluates the effective efficiency of its actual performance according to the actual bearing capacity of the vibration isolator (taking the ultimate bearing capacity as Standard) to optimize the use efficiency of each vibration isolator by continuously revising and adjusting the initial layout or traditional empirical layout, and finally determine the optimal solution for all vibration isolation devices to achieve the maximum utilization efficiency.

[0023] like figure 1 As shown, in the present invention, a method for optimal layout of a large-scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com