Heating device comprising a lamp removably mounted on an associated reflector

A technology of heating devices and reflectors, applied in the direction of ohmic resistance heating devices, etc., to achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, components having the same structure or similar functions will be denoted by the same reference numerals.

[0037] Hereinafter, the longitudinal direction, the vertical direction and the transverse direction represented by the coordinate system "L, V, T" of the drawings will be adopted without limitation. Here, the transverse direction is oriented from rear to front.

[0038] In the following, the term "inner" will be used to define the surface facing longitudinally towards the lamp tube 18 and the term "outer" will be used to define the surface facing in the opposite direction.

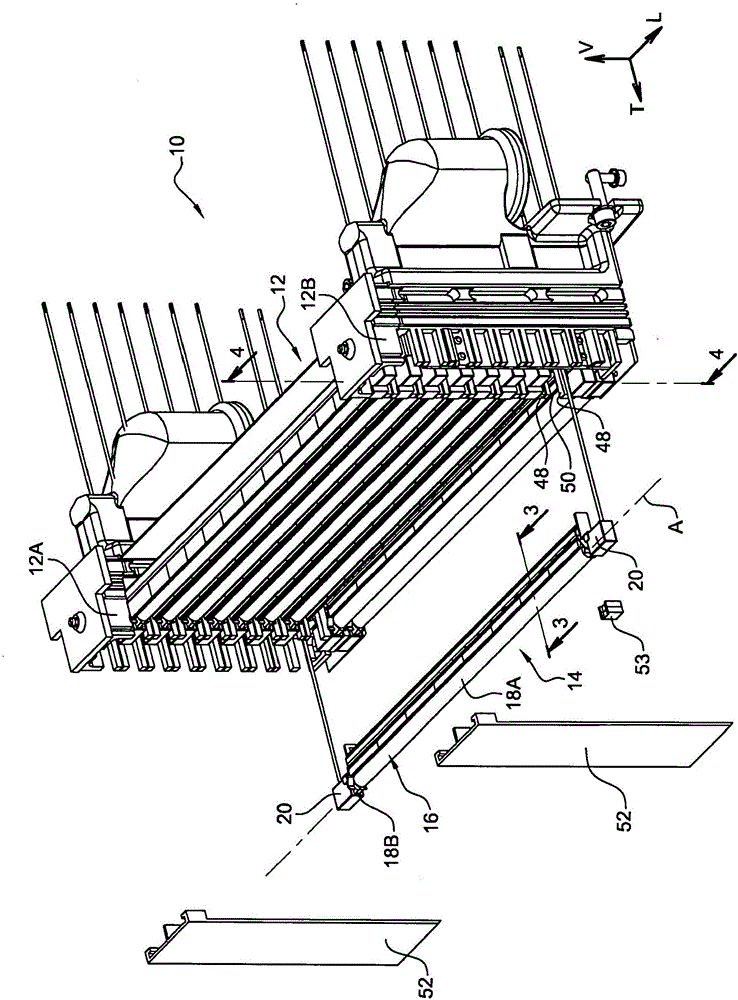

[0039] figure 1 A heating module 10 is shown in , which is used to equip a preform heating station (not shown). The heating module 10 has a support 12 for supporting a plurality of identical heating devices 14 .

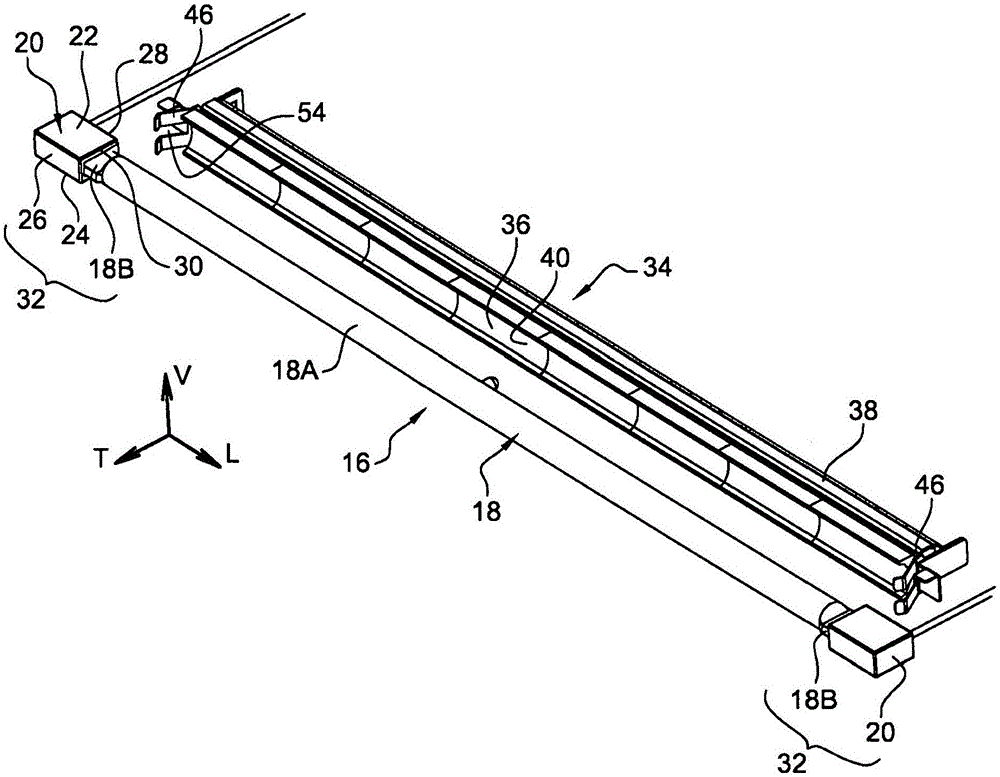

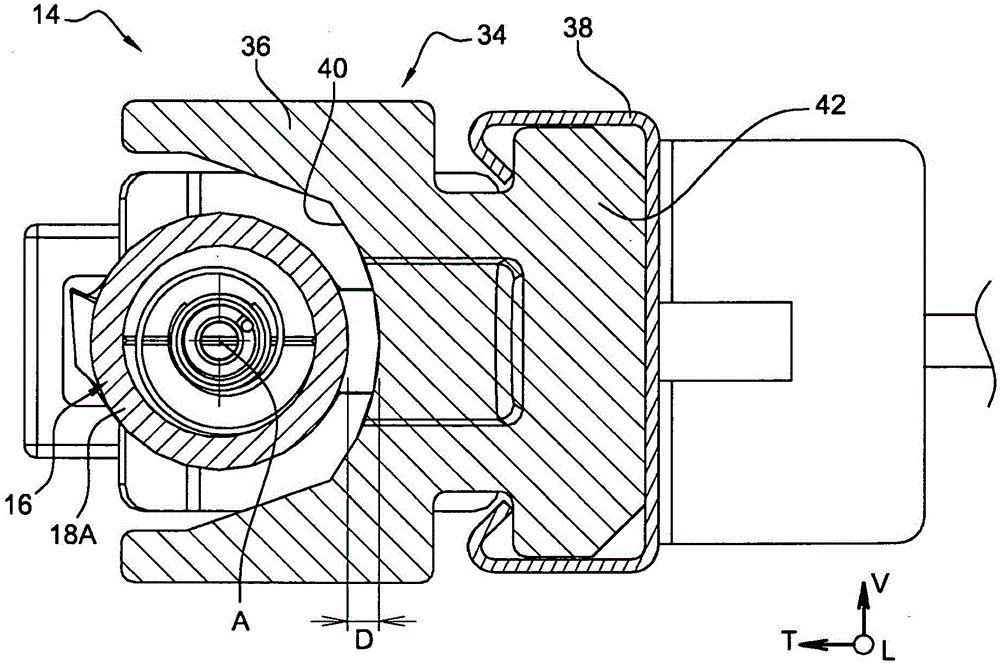

[0040] Such as figure 2 As shown, each heating device 14 has a lamp 16 . The lamp 16 has a lamp tube 18 with a longitudinal axis A. As shown in FIG. The lamp tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com