A method for making puff sleeves applied to shirts

A production method and a technology of puff sleeves, which are applied in the application, sewing tools, clothing and other directions, can solve the problem of insufficient beauty of the shoulder line and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

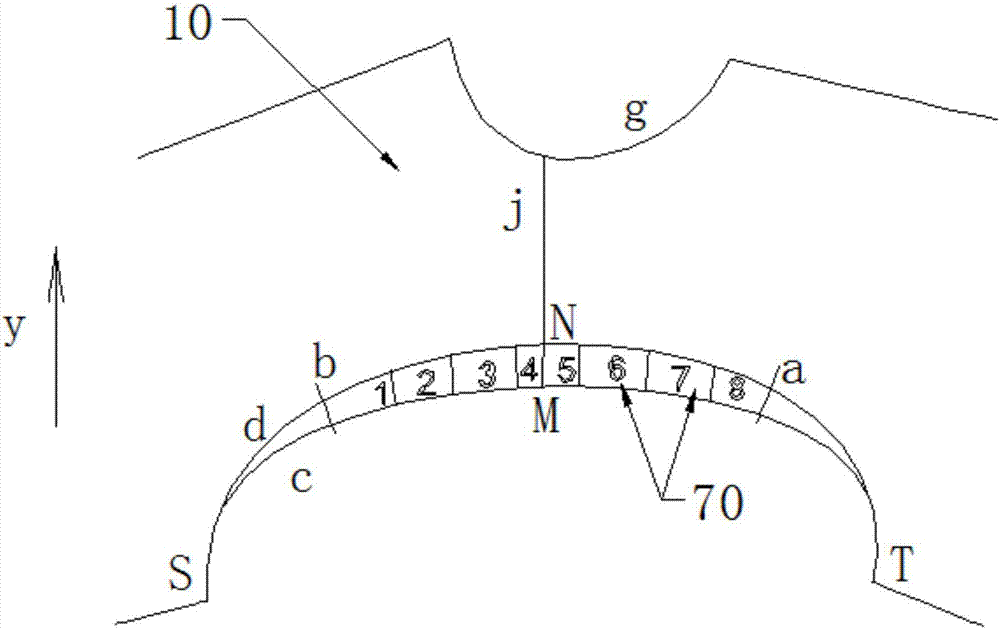

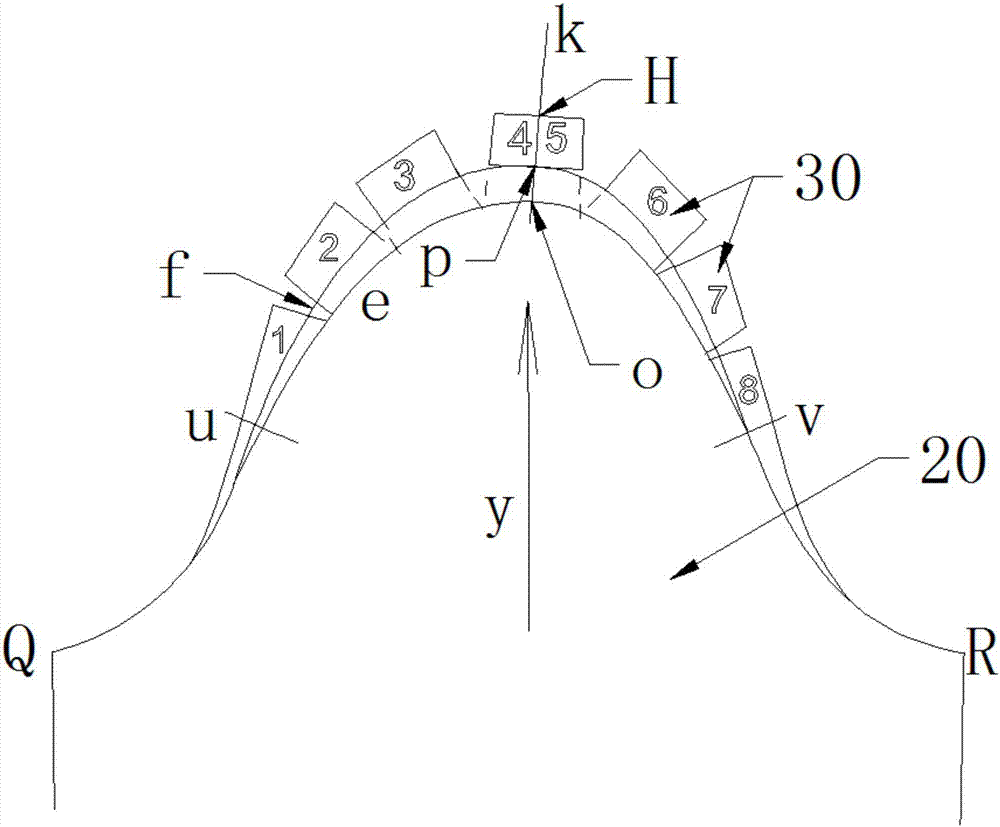

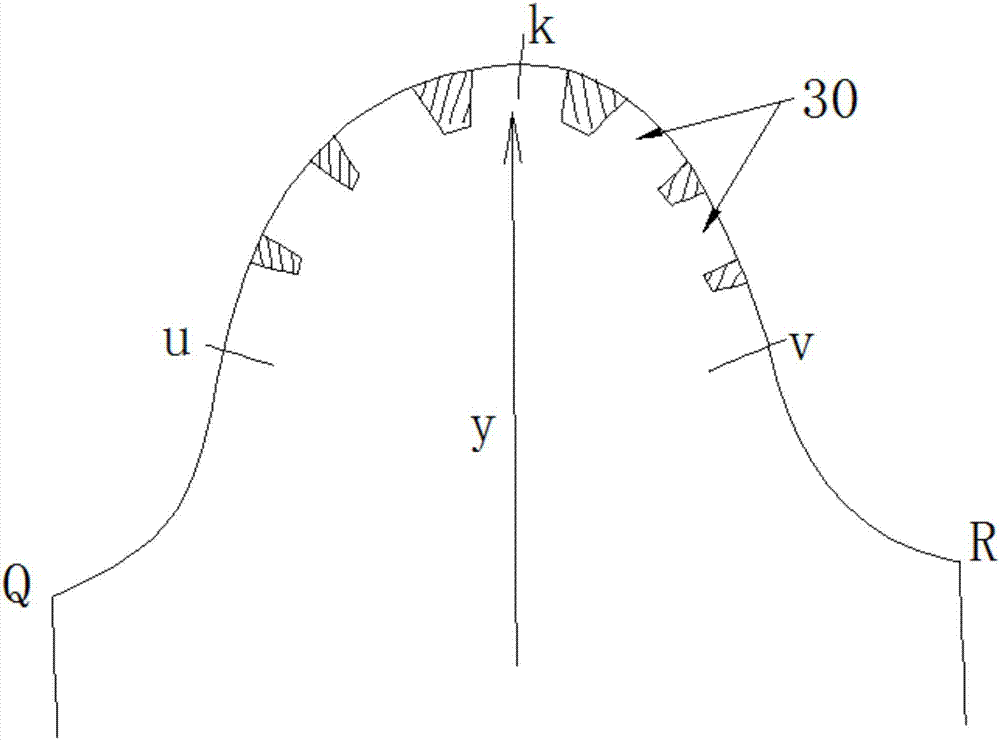

[0031] refer to figure 1 , is a structural schematic diagram of the shoulder part of the bodice version in the embodiment of the manufacturing method of the puff sleeve applied to the shirt, combined with figure 2 , is a structural schematic diagram of the sleeve mountain part of the sleeve version in the embodiment of the manufacturing method of the puff sleeve applied to the shirt, and image 3 , the structural plan view of the sleeve mountain part obtained by implementing the embodiment of the manufacturing method of the puff sleeve applied to the shirt, and Figure 4 , is a schematic diagram of the three-dimensional structure of the sleeve part obtained by implementing the embodiment of the manufacturing method of the puff sleeve applied to the shirt. And in order to clearly show the technical characteristics of the present invention, part of the structure is omitted, and it is defined as figure 1 , figure 2 The paper directions shown in are the positive directions, a...

Embodiment 2

[0046] The content and production process of this embodiment are basically the same as the above-mentioned embodiment 1, the only difference is that step 5 is:

[0047] On the shoulder part 10, draw two oblique lines a and b that intersect with the original armhole arc c and the new armhole arc d respectively, and from the oblique line a, oblique line b, and the original armhole arc c 1. The area enclosed by the new armhole arc b is used as the third pleat plate, and the third pleat plate is divided into several pleat blocks 70, that is, how many pleats are used; further, the oblique line a and the oblique line b The shoulder line j is arranged as a mirror image of the reference line, but is not limited thereto. And oblique line a and oblique line b are actually used as the end positions of both sides of the active pleats, and the specific positions are obtained according to the parameters of the number and width of active pleats in the design stage. Draw oblique line v corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com