Adhesive striping with apertured films

A technology of adhesive tape and perforated film, which can be used in bandages, medical science, sanitary napkins, etc., and can solve problems such as insufficient bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

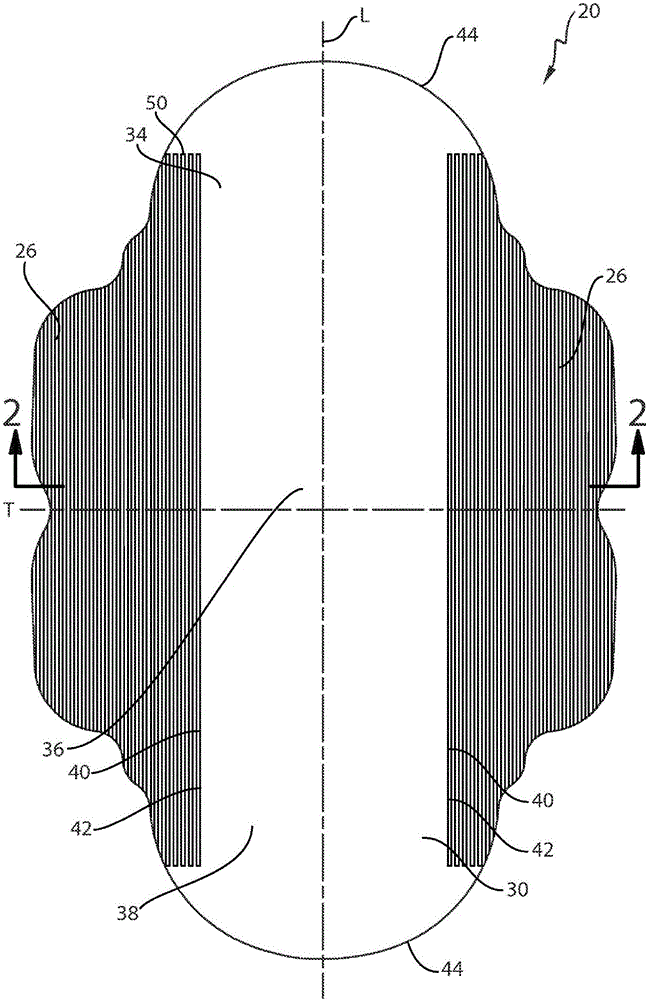

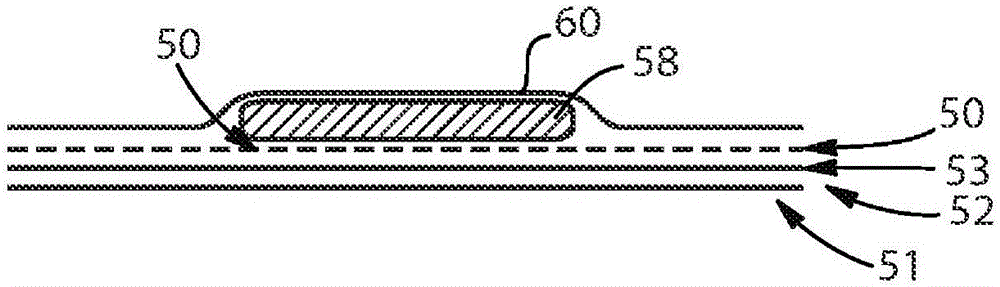

Method used

Image

Examples

Embodiment

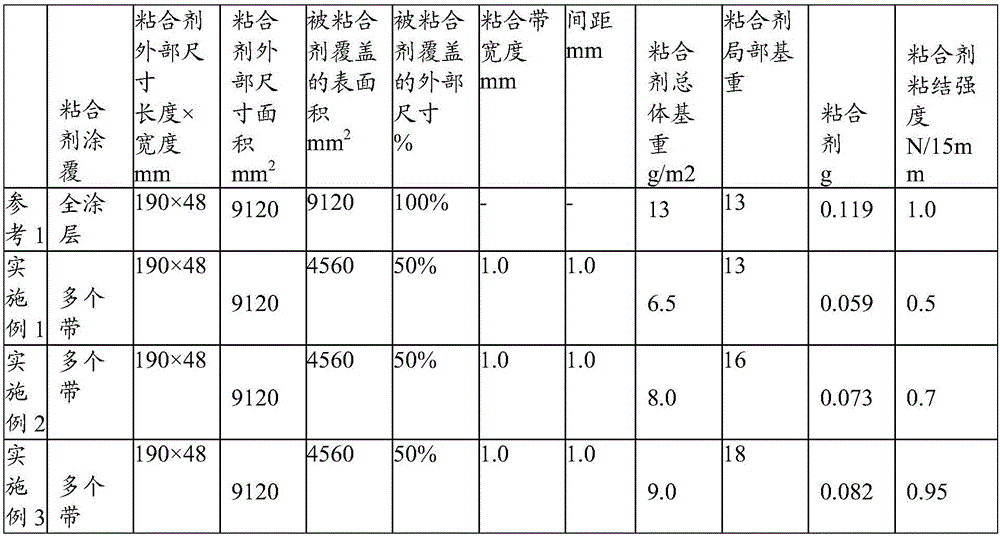

[0035] Table 1 shows four samples, referring to the data of Sample 1 and Examples 1-3, where the topsheet and backsheet laminates were bonded using multiple adhesive tapes. The laminates in all four samples were the same, ie, the bonded material was a backsheet film bonded to an apertured topsheet film, for use as eg a wing laminate. The adhesive used for all four samples was the same. All four samples have the same area of 190 x 48, or 9,120mm 2 .

[0036] For the reference sample, the adhesive was applied in a continuous layer covering the entire area of the sample at a spot basis weight of 13 gsm. This yielded 0.119 g of adhesive. Using the Standard Test Method for Peel Resistance of Adhesives, with modifications (described below), the resulting bond strength yields an adhesive bond strength of 1.0 N / 15mm.

[0037] For Examples 1-3, 50% of the area was coated with adhesive tape using a 1-to-1 slot adhesive pattern. The adhesive strips had a lateral width of 1 mm an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com