Horizontally-arranged single-power source vehicle drive assembly

A vehicle-driven, single-power-source technology, applied in the direction of hybrid vehicles, motor vehicles, power plants, etc., can solve problems such as the inability to use compact vehicles, the inability to adapt to complex road conditions, and the single speed ratio transmission of the powertrain. , to achieve the effect of making up for the lack of driving force of the whole vehicle, making up for the short life and improving the driving force of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

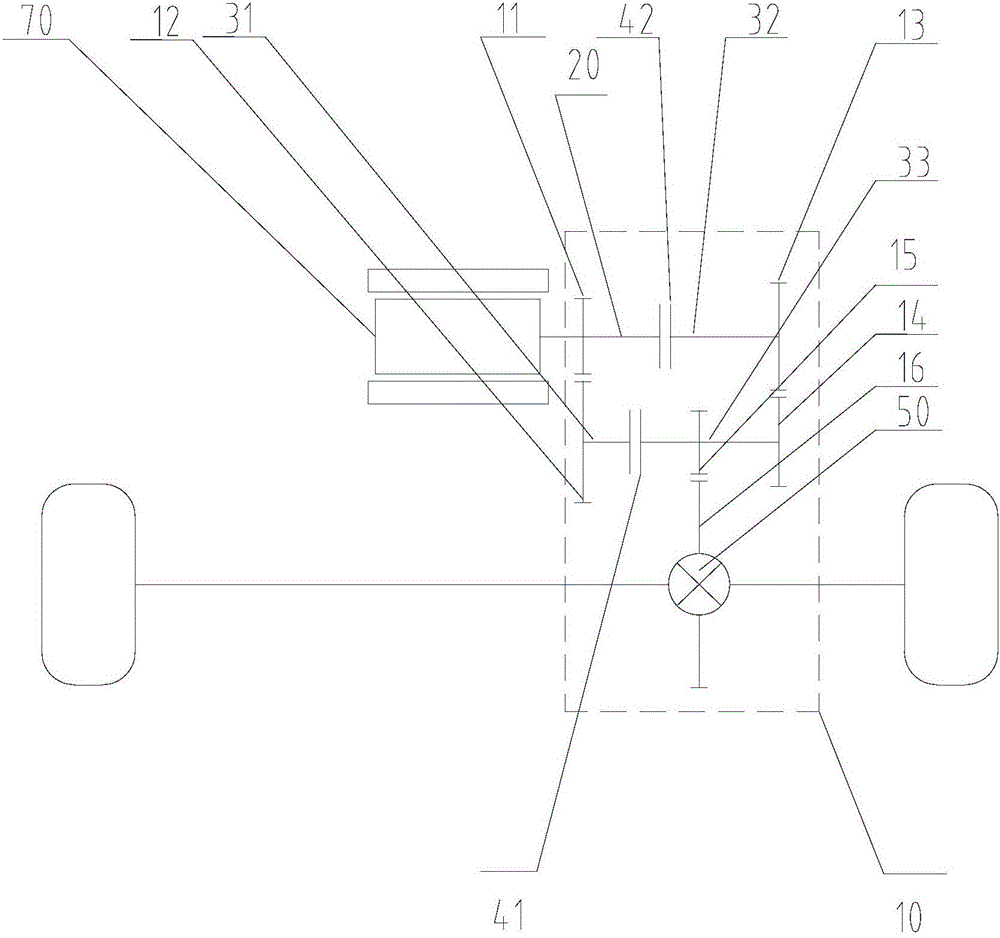

[0036] Such as figure 1 As shown, in Embodiment 1 of the present invention, a vehicle drive assembly with a single transverse power source is connected to the axle shaft. The vehicle drive assembly includes a power source and an automatic transmission 10, and the automatic transmission 10 is provided with an input shaft 20 , the power source is connected to the input shaft 20, and a differential 50 is arranged at the connection between the automatic transmission 10 and the axle shaft.

[0037] In Embodiment 1 of the present invention, the power source is the electric motor 70 , and the rotor shaft of the electric motor 70 is integrated with the input shaft 20 .

[0038] In the automatic transmission 10, a first intermediate shaft 31 is arranged parallel to the input shaft, a second intermediate shaft 32 is arranged in a direction coaxial with the input shaft 20, and a third intermediate shaft is arranged coaxially with the first intermediate shaft 31. 33 , a first clutch 41 i...

Embodiment 2

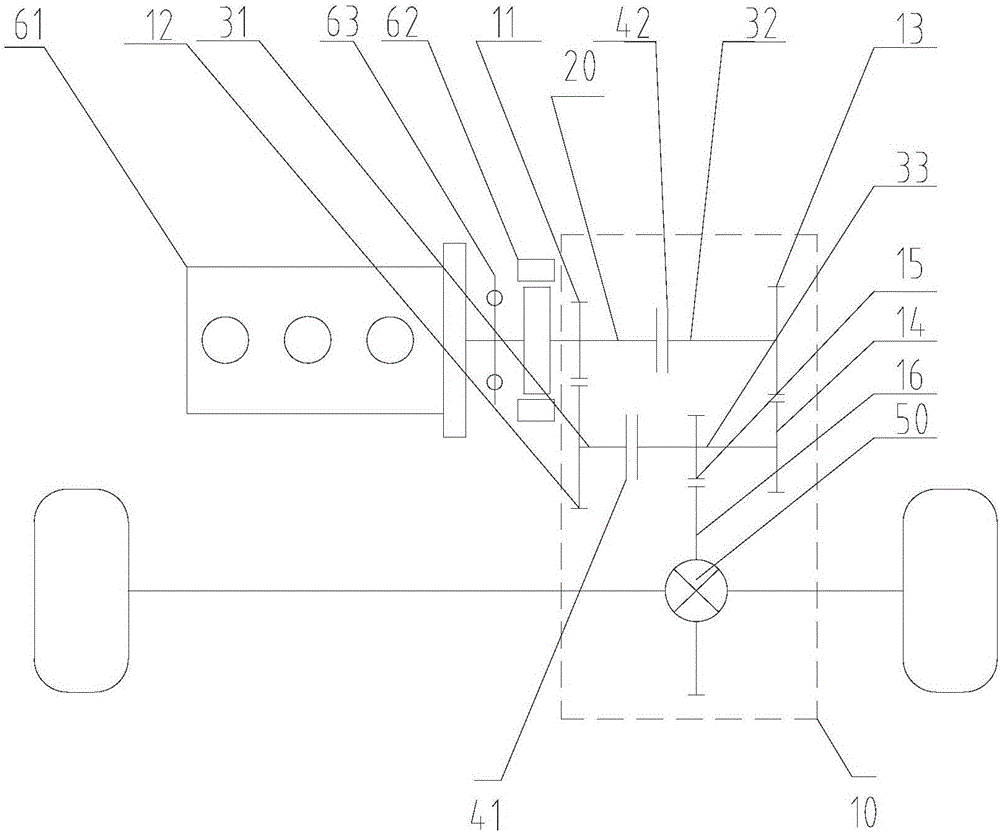

[0052] In Example 2 of the present invention, as figure 2 As shown, the power source is the combination of the engine 61 and the ISG motor 62. On the one hand, the idling loss and pollution of the engine are reduced, and on the other hand, the ISG motor acts as a generator, which can regenerate power, recover energy, and achieve energy saving effects. .

[0053] Other contents of Embodiment 2 of the present invention are the same as Embodiment 1, and will not be described again here.

Embodiment 3

[0055] In Example 3 of the present invention, as figure 2 As shown, a torsional damper 63 is provided between the engine 61 and the ISG motor 62, which has a buffering function and reduces the torsional stiffness of the junction between the engine and the ISG motor, thereby reducing the natural frequency of torsional vibration and eliminating torsional vibration.

[0056] Other contents of Embodiment 3 of the present invention are the same as Embodiment 1, and will not be described again here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com