Pod drive with traction propeller

A driving device, propeller technology, applied in the direction of rotating propeller, transportation and packaging, rotary propeller, etc., can solve the problems of resistance, stabilizer not optimizing flow, etc., to achieve the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

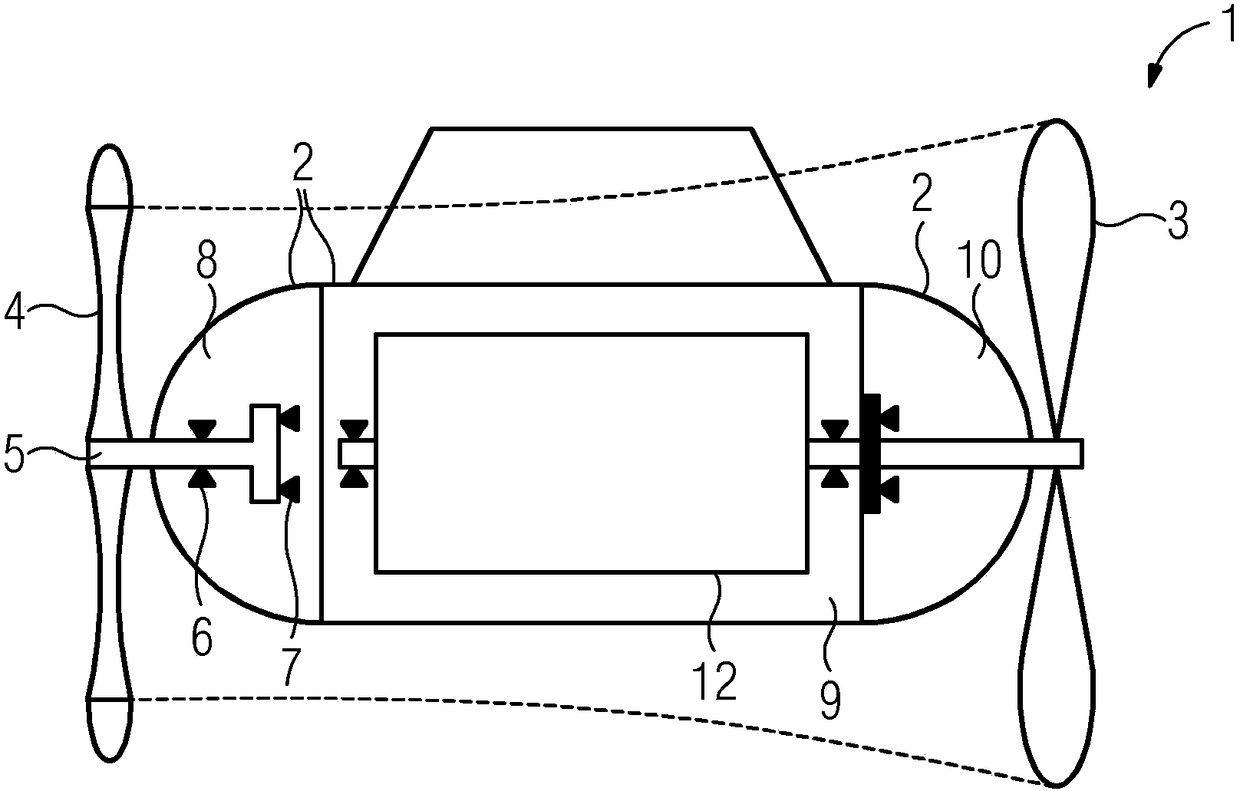

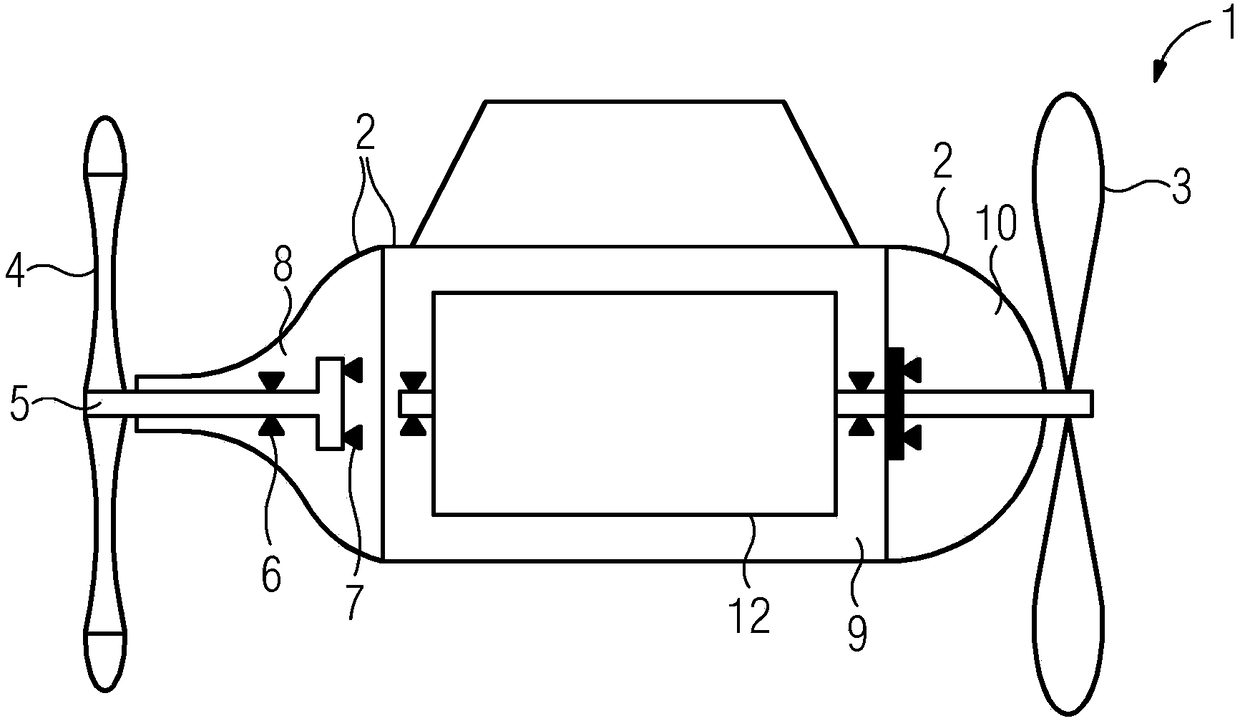

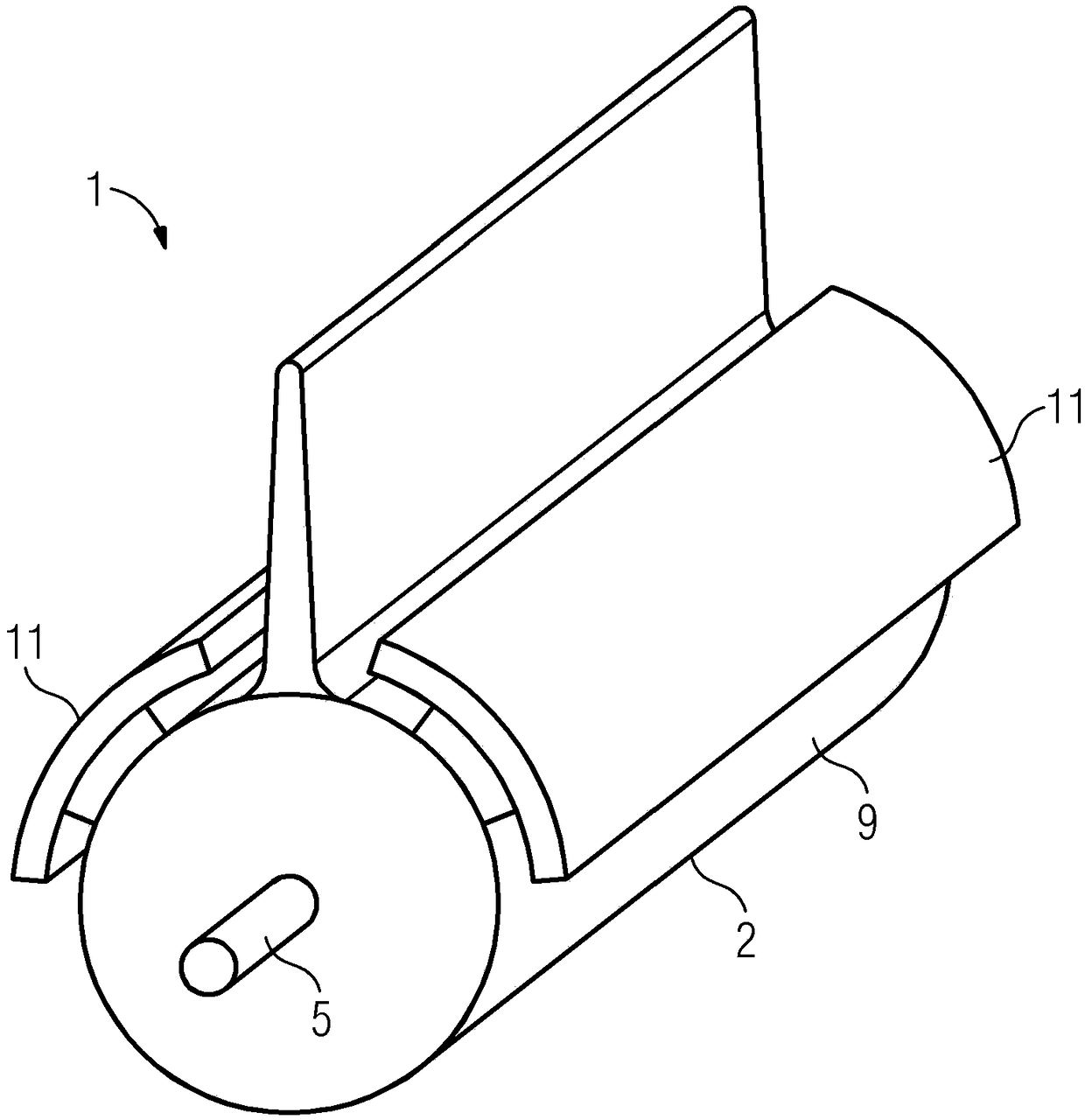

[0027] figure 1 Shown is a gondola drive 1 according to the invention with a housing 2, a traction propeller 3 and a guide wheel 4 at a guide wheel shaft 5, which is supported in part of the housing 2 by two bearings 6, 7. in paragraph 8. An electric motor 12 for driving the traction propeller 3 is accommodated in the other section 9 of the housing 2 , the shaft of which is supported by further bearings in the sections 9 and 10 . The dotted line between the traction propeller 3 and the guide wheel 4 indicates the jet constriction of the propeller jet, by means of which a guide wheel 4 with a diameter similar to that of the traction propeller 3 can be used. If the section 9 is sealed separately from the guide wheel section 8 , the guide wheel adapter 8 can function without an essential sealing element, since it is separated spatially and from the point of view of tightness from the rest of the POD. It is therefore advantageous here to use (sea) water lubricated bearings 6 , 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com