Production and dust-removal equipment for toilet paper

A technology for dust removal equipment and toilet paper, which is applied in the fields of removing smoke and dust, separating dispersed particles, chemical instruments and methods, etc., and can solve the problems of paper roll dust and unsanitary conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

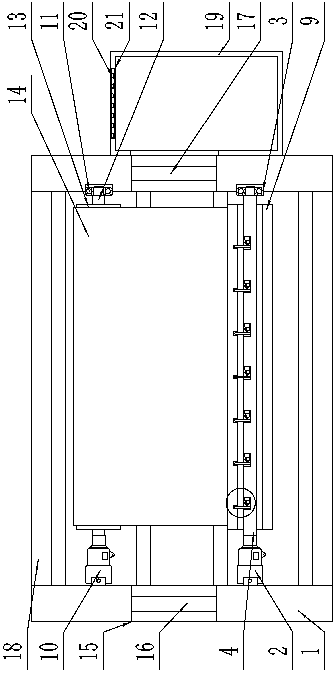

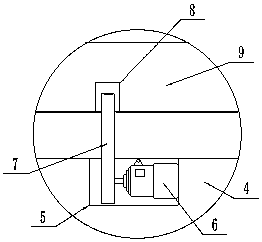

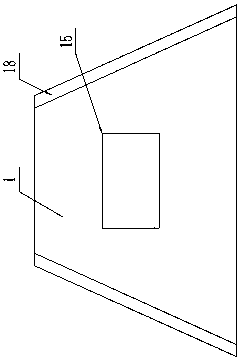

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a kind of dust removal equipment for toilet paper production includes a working stand (1). The working stand (1) is provided with a stable rotating mechanism, a dust removal mechanism and a belt turning mechanism. The belt turning mechanism is arranged on the working stand. The rotating motor A (2) and the bearing A (3) on the opposite side surfaces of the frame (1), one end inserted in the bearing A (3) and the other end fixed to the rotating end of the rotating motor A (2) rotating rod (4 ), a plurality of grooves (5) on the side surface of the rotating rod (4) equidistant along the straight line, a rotating motor B (6) set in the groove (5), and a set on the rotating end of the rotating motor B (6) The locking cam (7) and the rotating tube (9) which is set on the rotating rod (4) and has a plurality of grooves A (8) corresponding to the positions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com