Roll paper processing and treatment equipment

A technology for processing equipment and roll paper, applied in the direction of smoke removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as unhygienic, roll paper dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

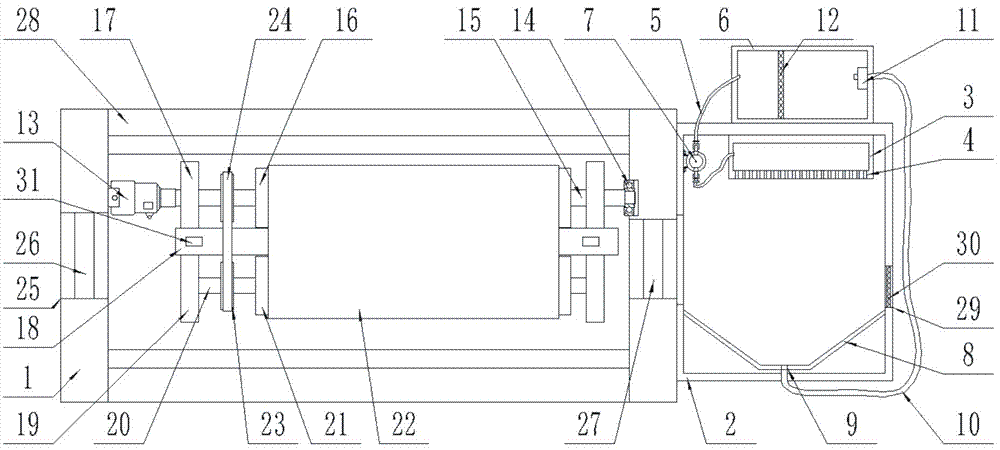

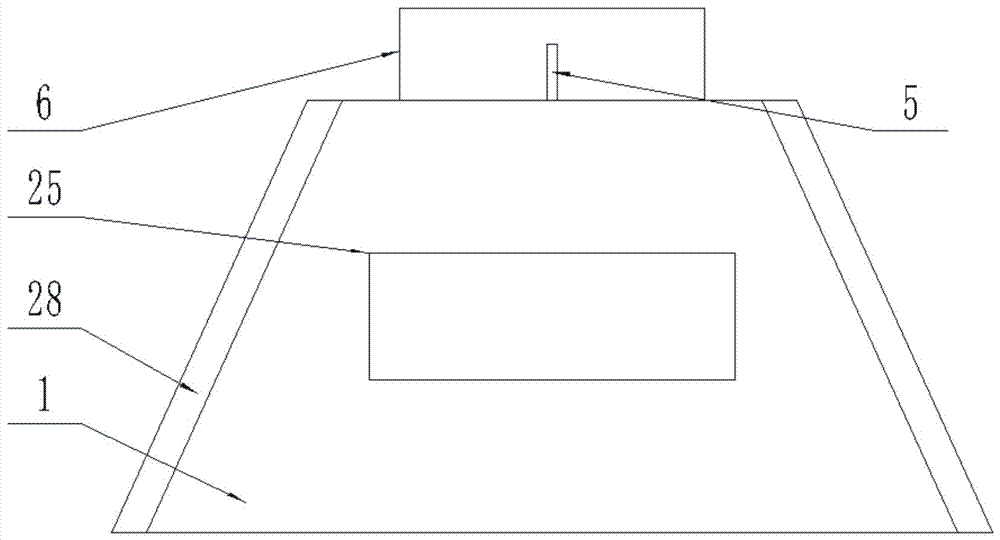

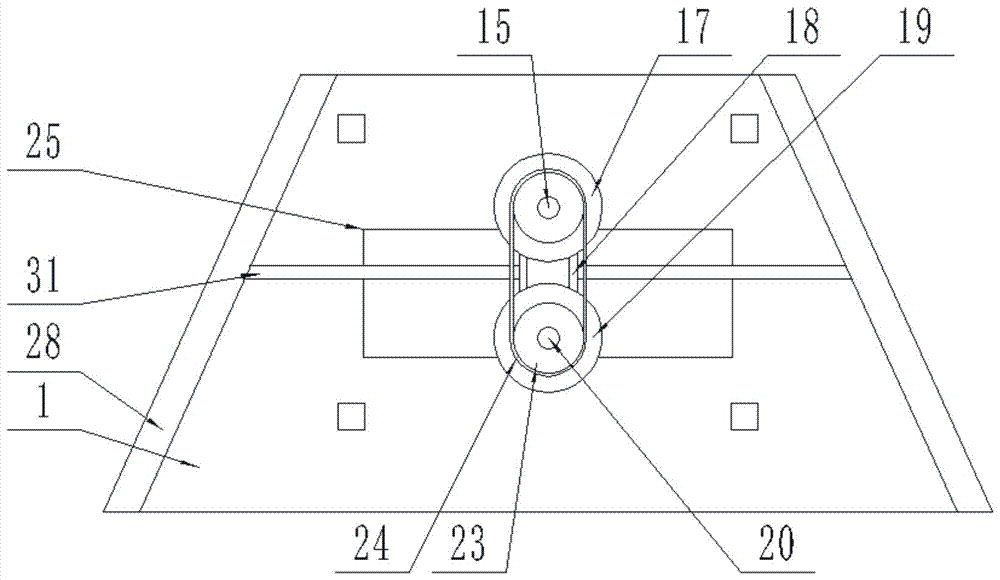

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a roll paper processing equipment includes a processing stand (1), a storage box (2) on one side of the processing stand (1), and a dust removal mechanism on the processing stand (1), The processing stand (1) is provided with a rotation transmission mechanism, and the dust collection mechanism consists of a horizontal straight pipe (3) arranged on the inner upper surface of the storage box (2), which is equidistantly opened under the horizontal straight pipe (3) along a straight line Multiple water seepage holes (4) on the surface, one end inserted into the storage box (2) and the water guide tube (5) connected to the water seepage hole (4), connected to the other end of the water guide tube (5) and placed on the storage box (2) The water tank (6) on the surface, the suction pump (7) arranged at the end of the water guide pipe (5) in the storage box (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com