Hot stamping aftertreatment equipment

A post-processing and equipment technology, which is applied in the field of hot stamping post-processing equipment, can solve the problems that paper dust cannot be cleaned, paper is easily contaminated with dust, and secondary pollution cannot be prevented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

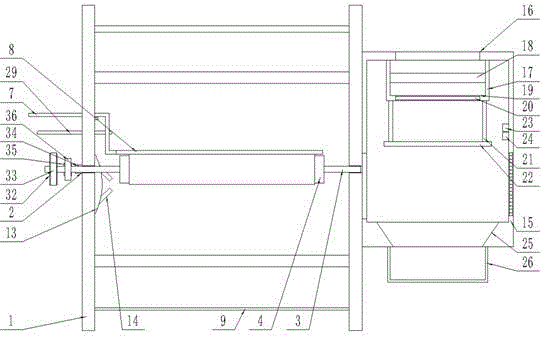

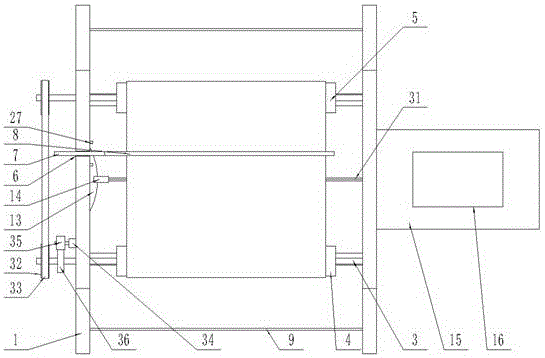

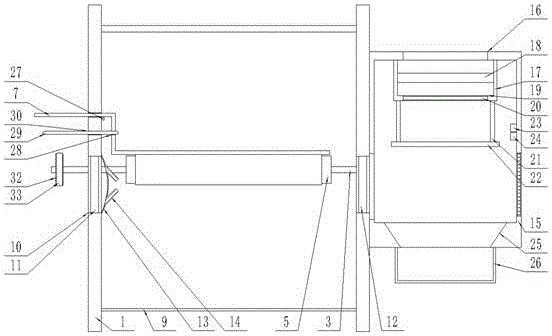

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a hot stamping post-processing equipment includes a working stand (1), and the working stand (1) is provided with a dust removal mechanism, a collecting mechanism and a rotating mechanism, and the rotating mechanism is opened on the working stand ( 1) Two sets of round openings (2) on the opposite sides, a pair of rotating rods (3) inserted in the two sets of round openings (2) at both ends, and rotating tubes A respectively fitted on the rotating rods (3) (4) With the rotating tube B (5), the round opening A (6) opened on the side surface of the working stand (1), a part of the rocker (7) embedded in the round opening A (6) and the fixing set The rocker (7) is inserted into the rotating finale (8) at the horizontal part of one end of the work stand (1). ), the openings (10) on the opposite side surfaces of the working stand (1), the air inlet fan (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com