Refrigerator stamping part folded edge forming die

A technology of stamping parts and forming dies, applied in the field of forming dies, can solve problems affecting production efficiency and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

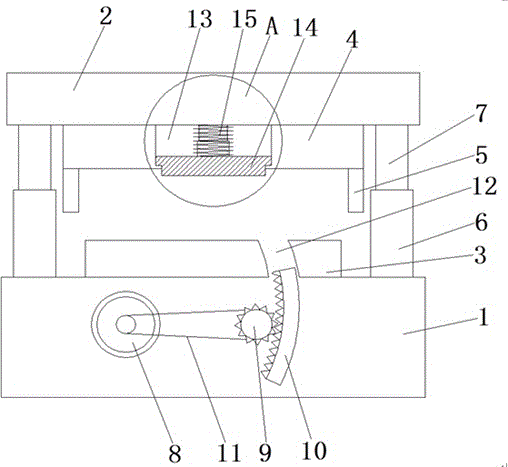

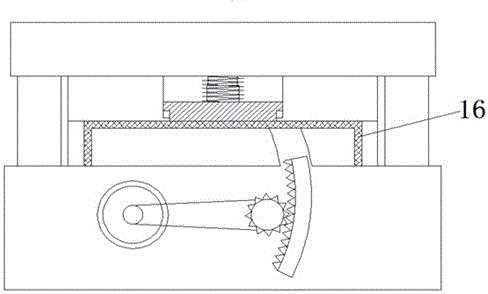

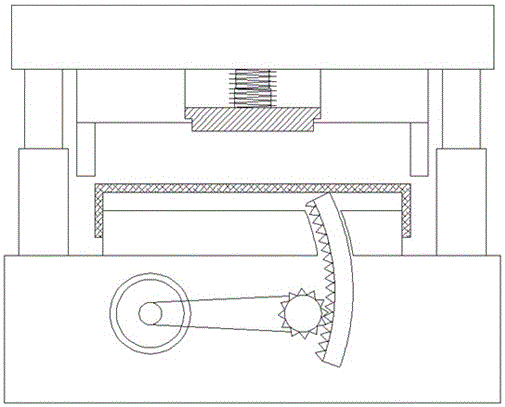

[0025] refer to Figure 1-4 , a folding mold for refrigerator stamping parts, including a corresponding fixed mold base 1 and a movable mold base 2, the fixed mold base 1 is arranged under the movable mold base 2, and the fixed mold base 1 and the movable mold base 2 pass through the first A telescoping rod is connected, and the top of the movable mold base 2 is connected with the power device, and is driven by the power device to move up and down. The first telescopic rod is composed of a sleeve 5 and an inner rod 7 which are nested with each other, and plays a guiding role;

[0026] A fixed module 3 is arranged on the top of the fixed mold base 1 , and a movable module 4 is arranged under the movable mold base 2 , and protruding blocks 5 for folding are respectively provided on both side edges of the movable module 4 . When folding the stamped part of the refrigerator, place the stamped part on the fixed module 3, the power device drives the movable die base 2 to move downw...

Embodiment 2

[0028] The middle position of the moving module 4 is provided with a through hole 13, and the through hole 13 is provided with a spring 15 and a lower pressing block 14. The bottom of the lower pressing block 14 stretches out from the through hole 13 of the driven module 4 before moving downward. The power device drives the movable mold base 2 to press down, and the lower pressing block 14 first contacts the stamping part, and under the force of the spring 15, the stamping part is pressed tightly to prevent the stamping part from being displaced, and then the movable mold base 2 continues to press down, and the bump 5 Fold the stamping parts to avoid the influence of the movement of the stamping parts on the processing accuracy. After the hemming is completed, the power device drives the movable mold base 2 to move upwards, and the movable module 4 is first separated from the stamping part. At this time, the lower pressing block 14 still exerts a downward force on the stamping...

Embodiment 3

[0030] In order to prevent the spring 15 from bending after a long time of use of the device, the spring 15 is provided with a second telescopic rod that can be retracted at will, and the second telescopic rod can maintain the verticality of the spring 15 to prevent the The spring 15 is bent, which affects the processing quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com