Spiral gear limiting device

A limit device, screw-type technology, applied in gear teeth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve problems such as pressure dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

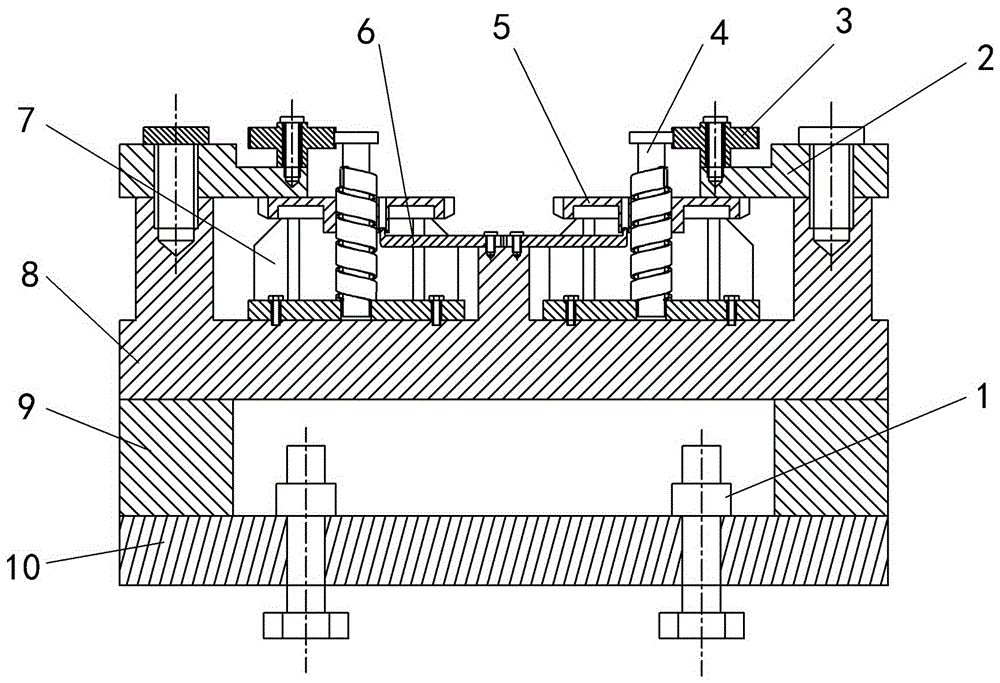

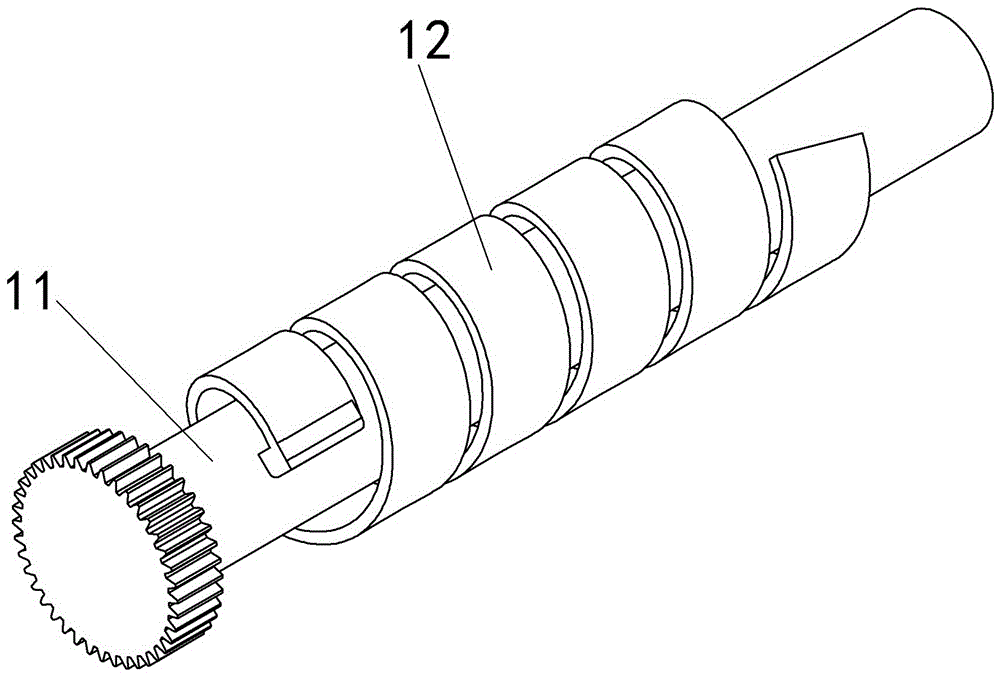

[0017] Example: such as figure 1 , The helical gear limiting device in this technical solution includes a base and a clamp assembly installed on the base. There are six sets of clamp assemblies on the base, distributed in a 2×3 matrix. The base is composed of an upper base plate 8, a lower base plate 10, and a backing plate 9 arranged between the upper and lower base plates 10. The upper base plate 8 and the lower base plate 10 are connected together by screws, and the outer periphery of the base plate is provided with lifting bolts. The lower base plate 10 is provided with T-bolt 1 for connecting the machine tool. The clamp assembly includes a gear 5 supporting seat 7, a fixed element group 4, a positioning block 6, and a pressure block 2. The supporting seat 7 is in the shape of a disk, and the outer circumference of the disk extends upwards with pillars arranged at intervals. The support seat 7 is fixedly installed on the base, and the top of the support seat 7 is horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com